Valve

A valve and valve disc technology, applied in the application field of the valve, can solve problems such as bearing and seal damage, and achieve the effect of simplifying positioning and minimizing structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

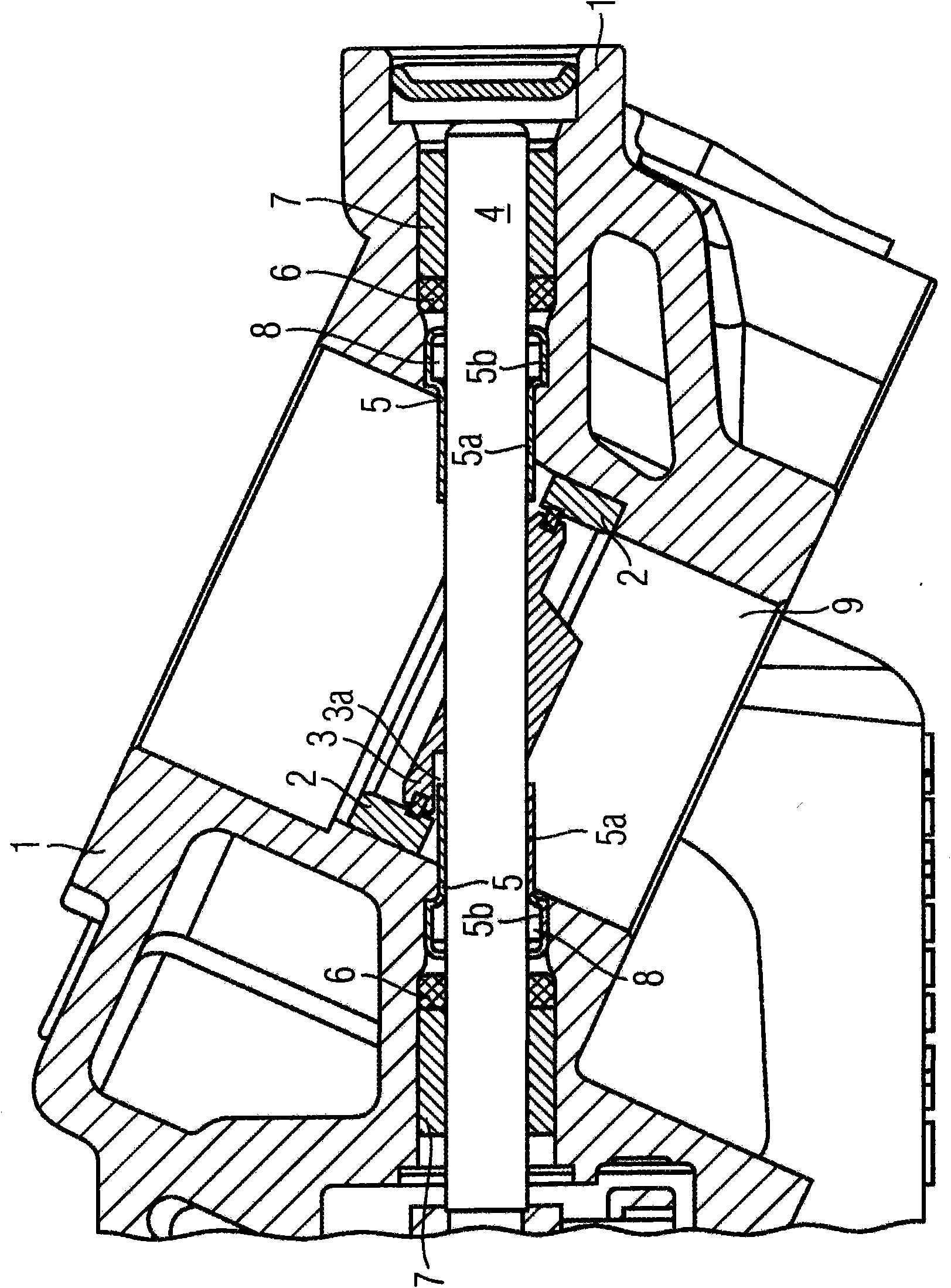

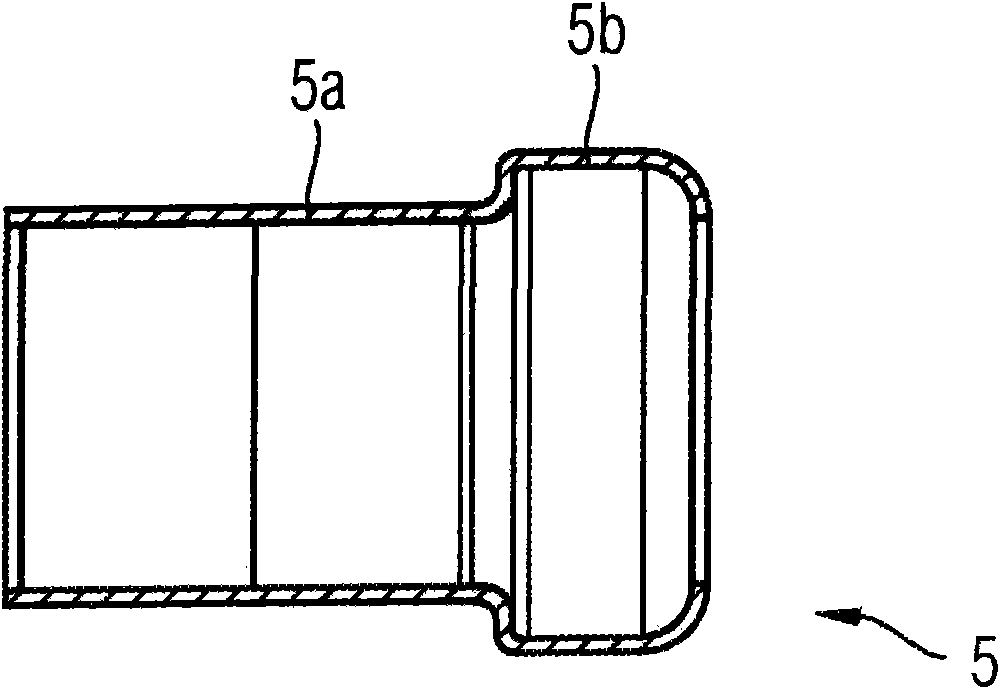

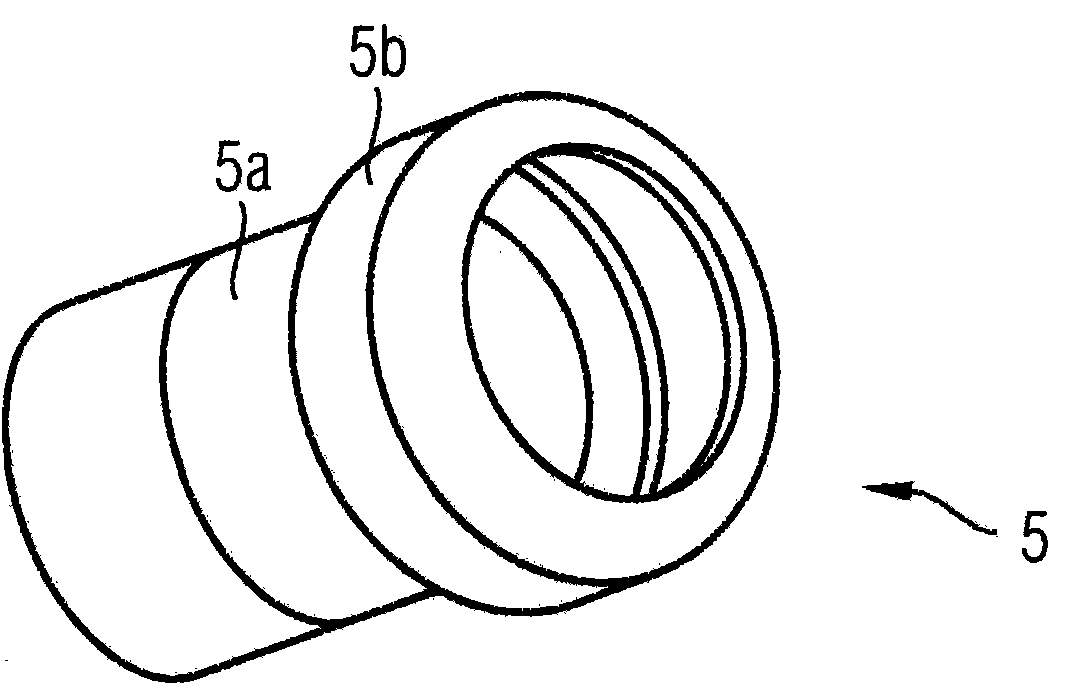

[0016] figure 1 A longitudinal section view of the valve is shown. The valve comprises a housing 1 with a valve seat 2 for a valve flap 3 which is rotatably supported on a drive shaft 4 . The drive shaft 4 is guided through the housing 1 on both sides. In this region, a sleeve 5 is arranged in a stationary manner in the housing 1 , through which sleeve the drive shaft 4 is rotatably guided. The sleeve 5 has a first region 5a which faces the valve flap 3 and surrounds the drive shaft 4 with a first gap. Furthermore, the sleeve 5 has a second region 5 b facing away from the valve flap 3 and having an enlarged diameter compared to the first region 5 a and enclosing the drive shaft 4 with a second gap on its end face facing away from the valve flap 3 . A storage space 8 is formed by the diameter expansion, which is suitable for collecting pollutants or condensed water. An annular seal 6 and a bearing 7 are arranged around the drive shaft 4 in the vicinity of the end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com