Automatic feeding method for sows and piggery applying same

A feeding method and technology for breeding sows, applied in the field of sow feeding, can solve problems such as delaying the feeding time of sows that have not yet eaten, reducing the efficiency of automatic feeding sows, and affecting the development of sows, so as to improve automation Effects of feeding efficiency, faster feeding speed, and reduced feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

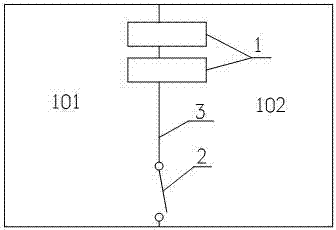

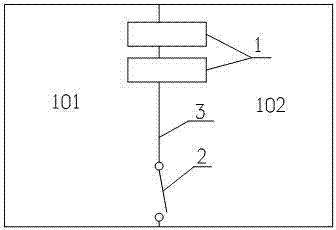

[0011] Such as figure 1 As shown, the pigsty used in the present invention is provided with a fence 3, and the fence 3 separates the pigsty into two relatively independent areas of the area to be fed 101 and the area 102 that has been fed. The size is basically the same. In the fence 3, a fence gate 2 and two sow feeding devices 1 are arranged side by side. The sow feeding device 1 is provided with a one-way passage connecting the area to be fed 101 and the area 102 that has been fed. In practical application, the sow feeding device 1 can adopt an existing automatic feeding station, which is provided with a feeding channel surrounded by fences on both sides and only for a single sow to pass through in one direction. The entrance and exit of the channel are respectively provided with one-way doors, and a sow automatic feeding machine controlled by a computer is installed between the entrance and the exit in the channel. The electronic ear tags are used to identify and distingu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com