Gas-liquid linked dismounting device of fan impellers

A gas-liquid linkage, fan impeller technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low disassembly efficiency, limited disassembly space, time-consuming alignment, etc., and achieve the effect of improved disassembly and efficient disassembly.

Active Publication Date: 2010-09-22

HAISAI NEW TECH CHANGSHA

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the special structure of the centrifugal fan impeller and its shaft sleeve, Rama cannot be used to disassemble the impeller

At the same time, due to the limited disassembly space of the impeller, it takes time to disassemble the impeller with a simple fixture such as a clamp device, and the disassembly efficiency is low. The manual disassembly method is to knock the impeller shaft sleeve from one side of the impeller with an iron rod or hammer , it is time-consuming and laborious, and it is easy to cause damage to the fan impeller and motor shaft, and even cause the entire fan to be scrapped. Therefore, there has been no efficient impeller removal device at present.

For the rusty centrifugal fan at the junction of the impeller shaft sleeve and the motor shaft, there is no set of effective disassembly methods and disassembly tools.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

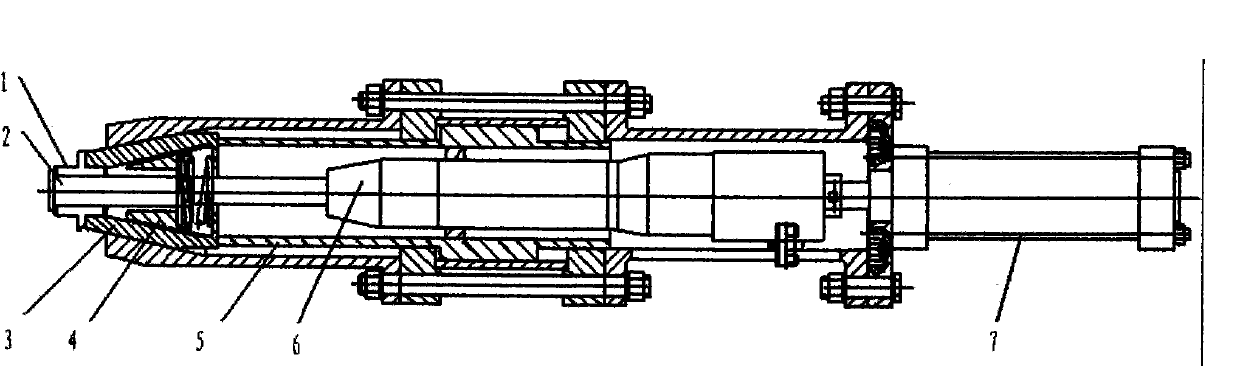

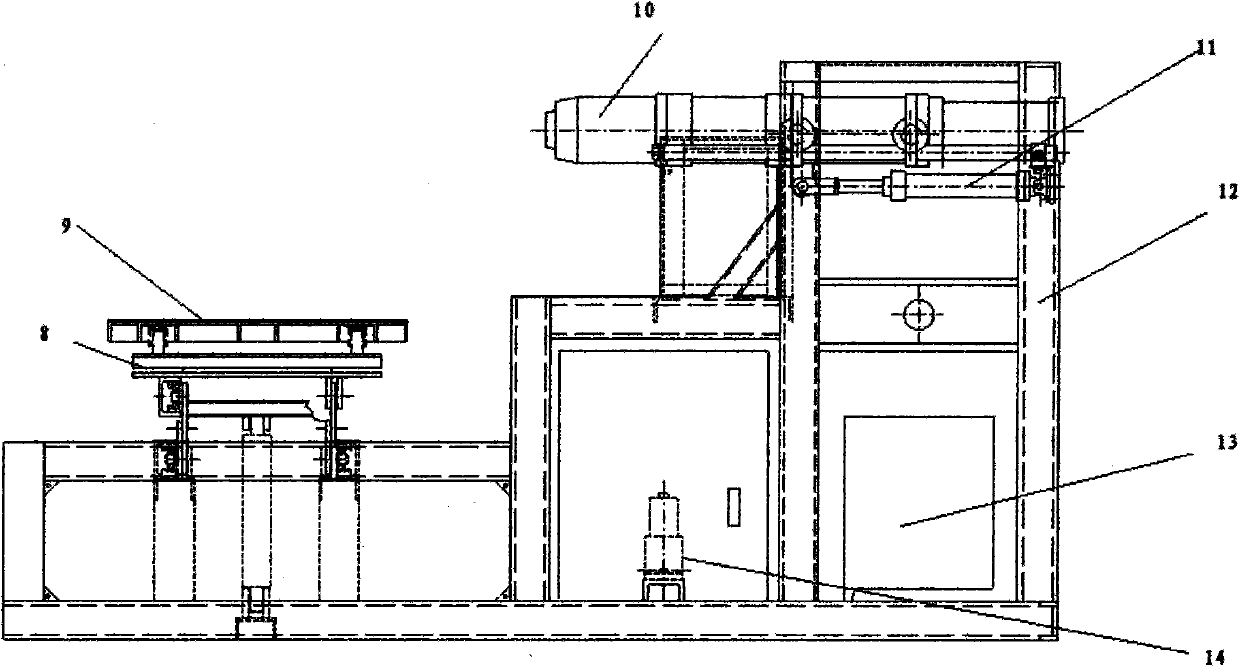

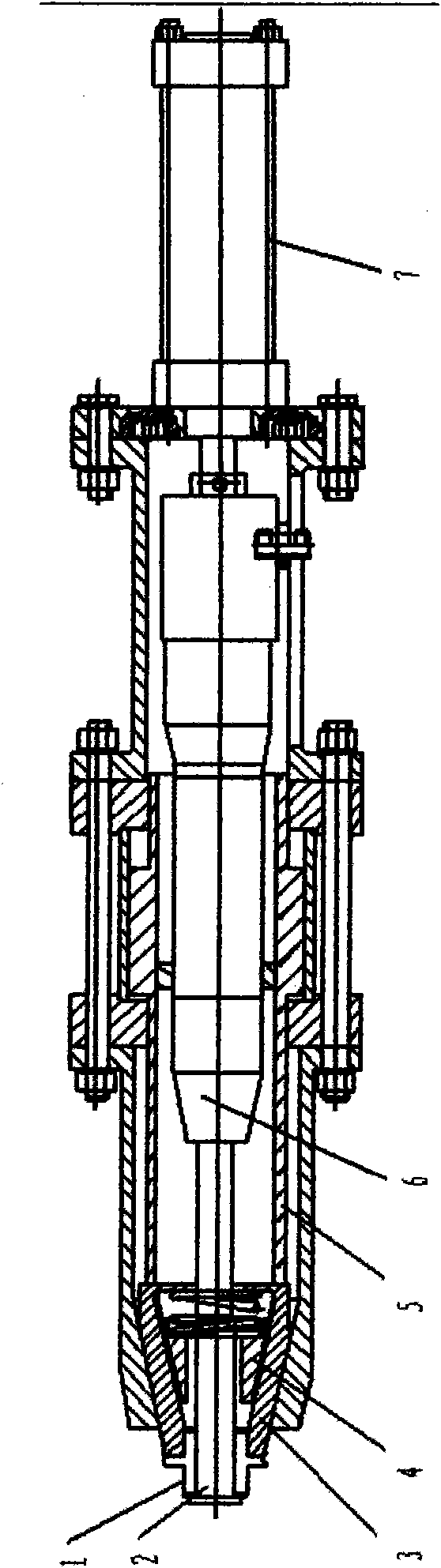

Login to View More Abstract

The invention relates to a gas-liquid linked dismounting device of fan impellers, mainly comprising a stand, a hydraulic system, a pneumatic system, an electrical control system, a dismounting operation device, a lifting table and a rotating platform. The gas-liquid linked dismounting device is characterized in that impeller shaft sleeves are clamped by adopting the hydraulic system, a motor shaft is impacted by the pneumatic system for the gas-liquid linked dismounting of the fan impellers, a jaw part is provided with teeth and is locally quenched, the lifting table adopts a scissors fork type structure and has a high lifting speed and a low lifting speed, wherein the low lifting speed is used for dismounting alignment. When the impellers at both ends of a fan are dismounted, the fan is placed on the platform, and then the two impellers can be rapidly dismounted by utilizing the rotation and the lifting of the platform; and a clamp head is pushed to clamp the impeller shaft sleeves by an oil cylinder, an impacting mechanism carries out flexible impacting and loosening on the motor shaft, an uploading air cylinder generates static thrust for the impact mechanism and applies the static thrust to the motor shaft, and the motor shaft is pushed out of the impeller shaft sleeve under the actions of a dynamic load and a static load. The invention can prevent the fan impellers, the impeller shaft sleeves and the motor shaft from being damaged when the fan is dismounted, thereby greatly improving a dismounting effect.

Description

technical field The invention relates to fan equipment, in particular to a gas-liquid linkage dismantling device for a fan impeller applied to the disassembly of a centrifugal fan impeller. Background technique Existing centrifugal fans all include impellers. When the fan is working, the impellers are easily dirty, which affects the performance of the centrifugal fan, and is also easy to damage the impellers. The impellers need to be removed regularly for cleaning and maintenance. In the maintenance of centrifugal fan, the disassembly of centrifugal fan impeller is an important maintenance work. Due to the special structure of the centrifugal fan impeller and its shaft sleeve, Rama cannot be used to disassemble the impeller. At the same time, due to the limited disassembly space of the impeller, it takes time to disassemble the impeller with a simple fixture such as a clamp device, and the disassembly efficiency is low. The manual disassembly method is to knock the impelle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P19/027

Inventor 成新明周春华

Owner HAISAI NEW TECH CHANGSHA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com