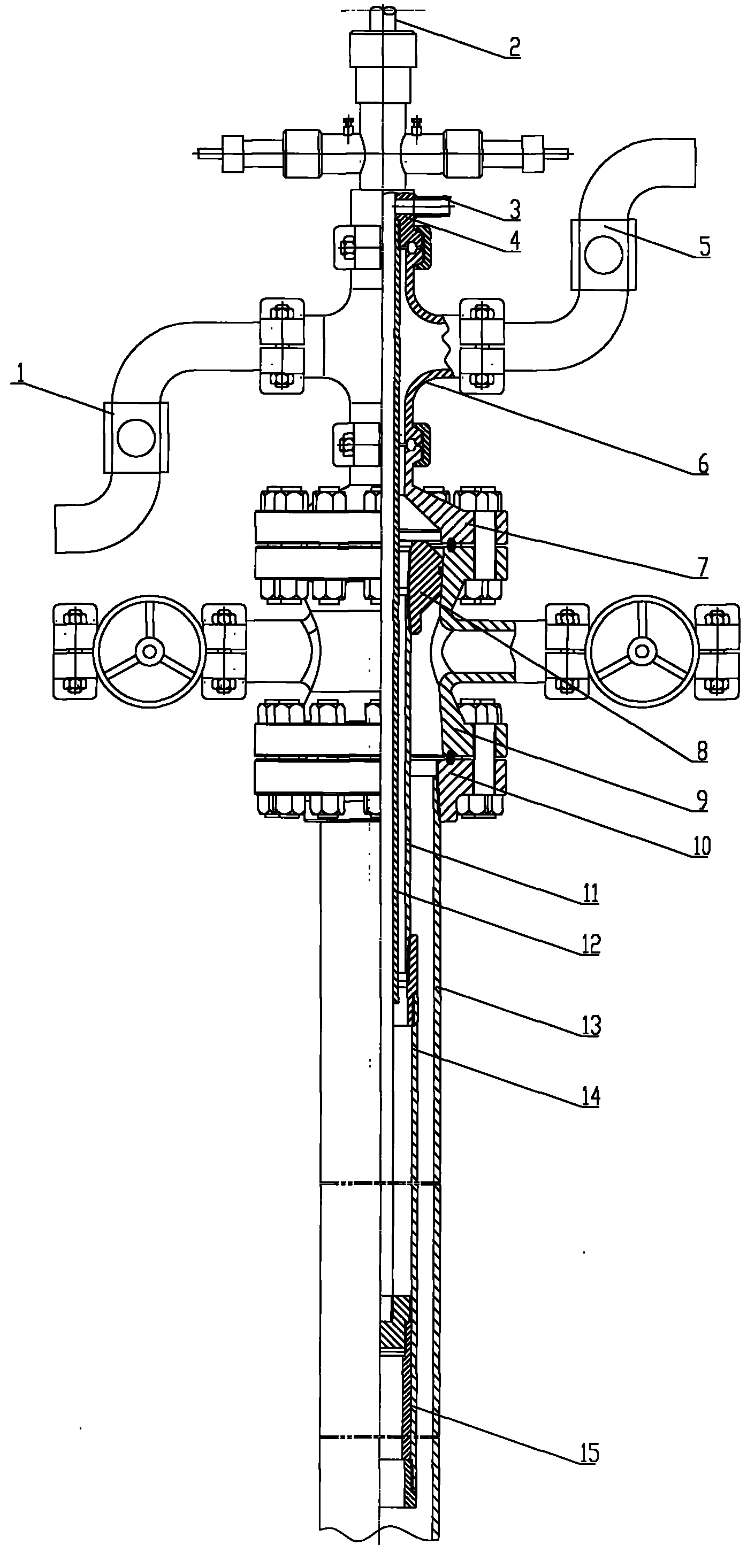

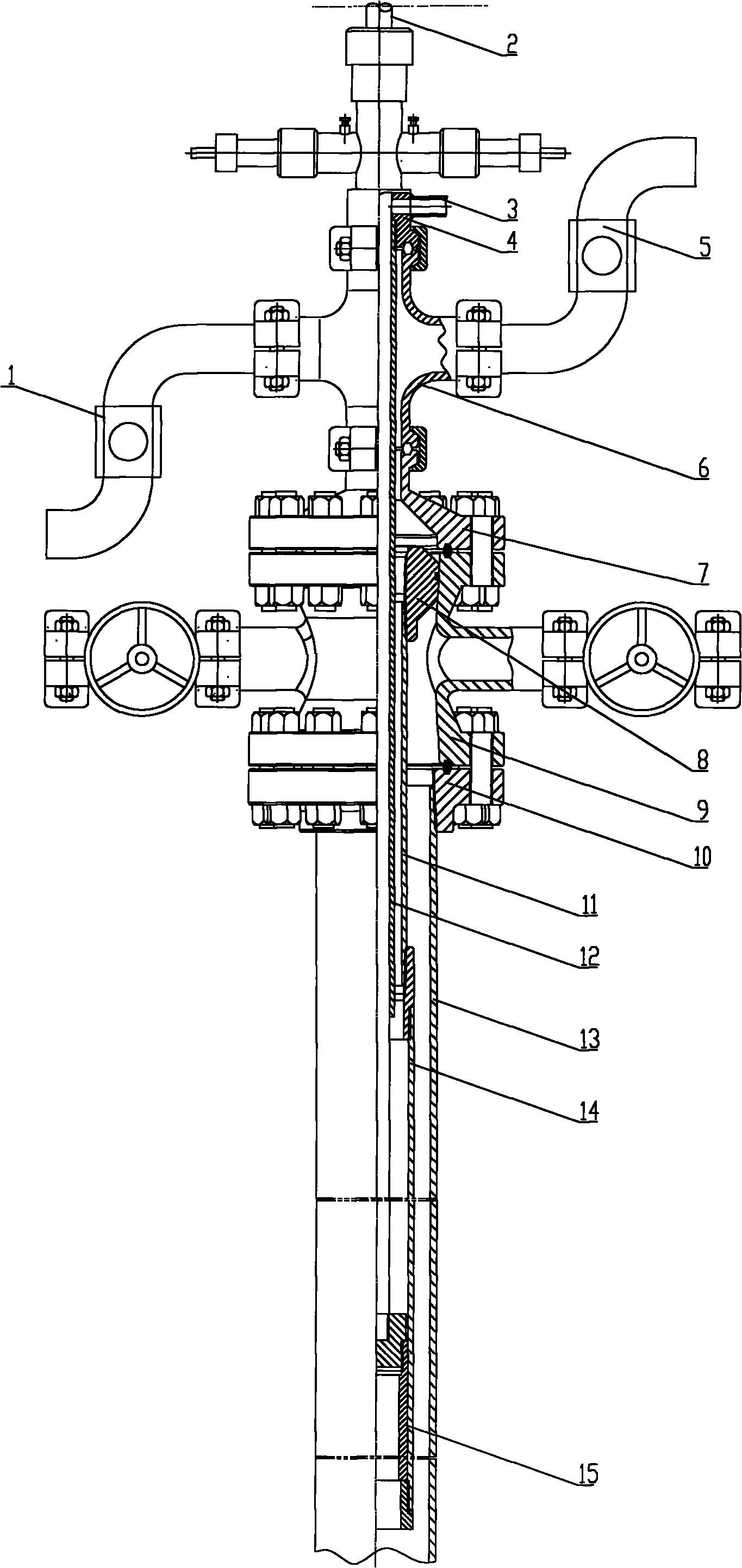

Pressurized water injection device

A booster pump and four-way technology, applied in the field of equipment for oil field water injection, can solve the problems of inability to improve the permeability of the water injection layer, economic losses, frequent maintenance, etc., achieve significant economic and social benefits, improve permeability, and manage low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. As shown in the figure, the embodiment of the present invention consists of a liquid inlet valve 1, a polished rod 2, a pressure relief pipe 3, a sealer 4, a liquid discharge valve 5, a small cross 6, an upper flange 7, a hanger 8, and a large cross 9. Lower flange 10, inner pump barrel 11, casing 12, booster pump barrel 13, booster plunger 14, small cross 6, upper flange 7, large cross 9, lower flange 10 from the upper Connect from bottom to bottom, the upper part of the casing 12 is connected to the lower flange 10, the hanger 8 is installed in the large cross 9, and is sealed with the large cross 9, the liquid inlet valve 1 is installed on the side of the small cross 6, and the small four The drain valve 5 is installed on the other side of the passage 6, the pressure relief pipe 3 is installed at the lower part of the sealer 4, the pressure relief pipe 3 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com