Cloth bonding apparatus

A cloth bonding and adhesive technology, applied in the field of cloth bonding devices, can solve the problems of unable to control the pressure, unable to reach sufficient gas pressure in the storage room, unable to press out the adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

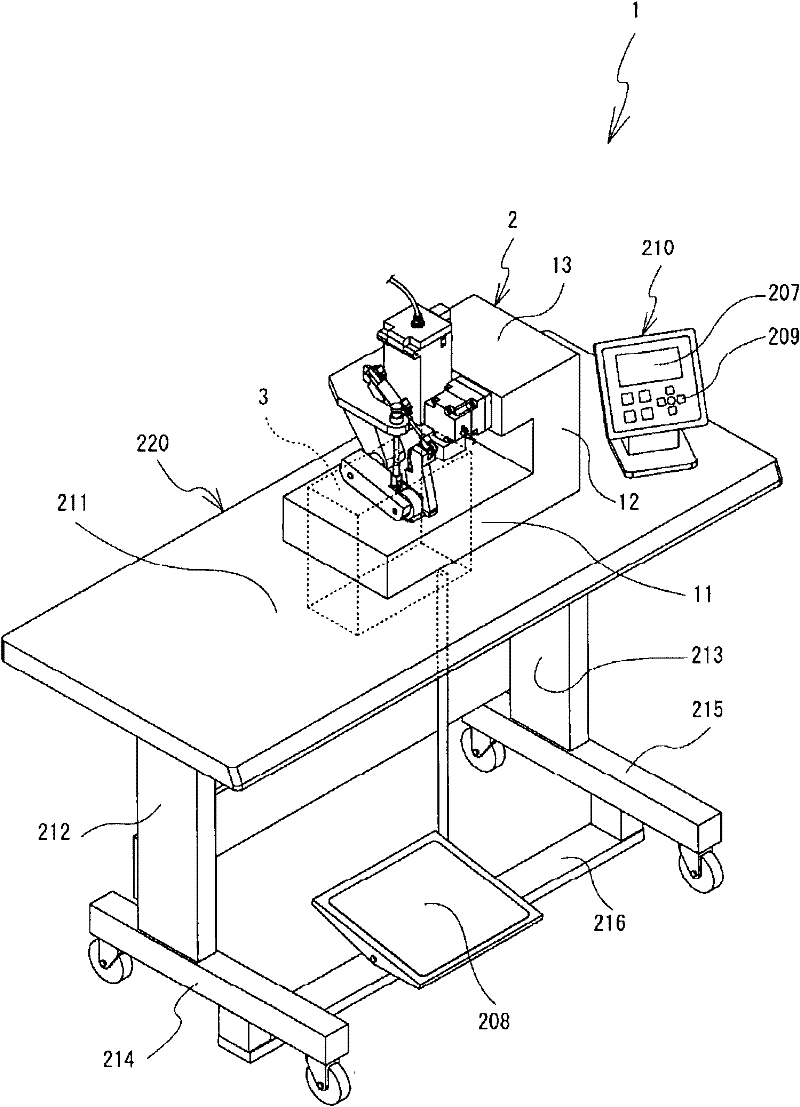

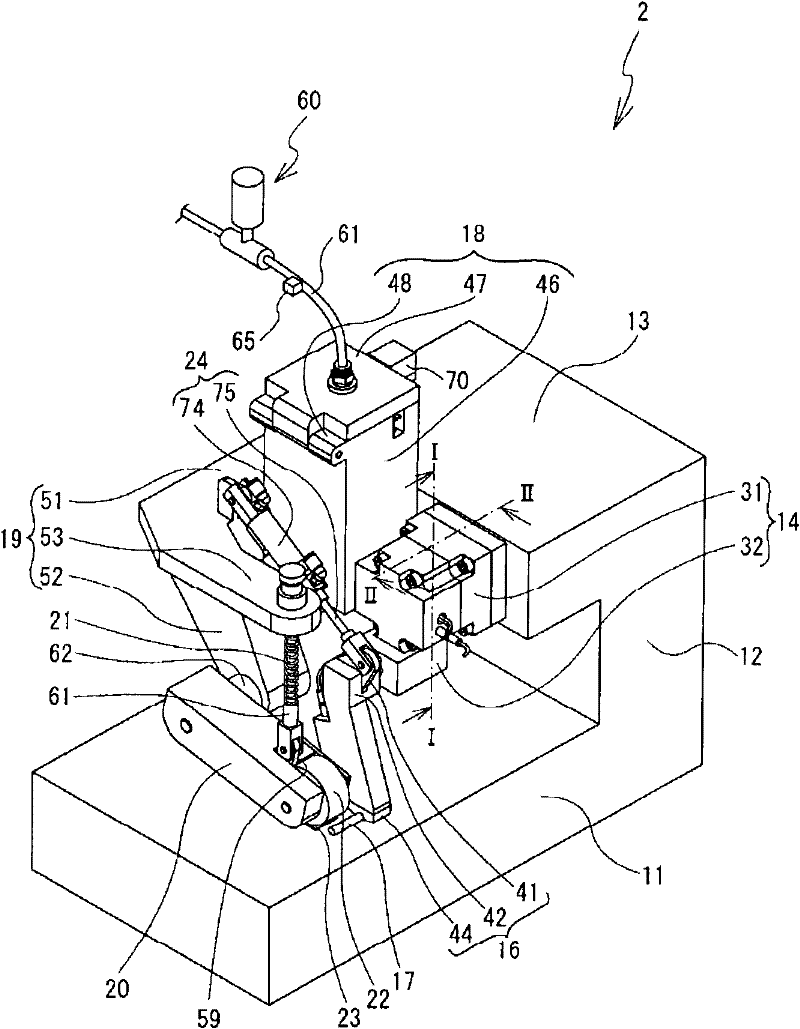

[0032] Next, a first embodiment of the cloth bonding apparatus 1 of the present invention will be described with reference to the drawings.

[0033] refer to Figure 1 to Figure 4 , the structure of the cloth bonding apparatus 1 will be described. Next, put image 3 The upper side, the lower side, the right side, the left side, the front side, and the back side of the bonding machine 2 are defined as the upper side, the lower side, the right side, the left side, the front side, and the back side of the bonding machine 2 respectively. Explained on the back side.

[0034] Such as figure 1 As shown, the cloth bonding apparatus 1 includes a bonding machine 2 and a use table 220 . The bonding machine 2 is fixed using a table 220 . The bonding machine 2 applies an adhesive between two layers of cloths arranged opposite to each other, and presses and feeds the cloths. The two layers of cloth are bonded by the above operation of the bonding machine 2 . The detailed structure of...

no. 2 approach

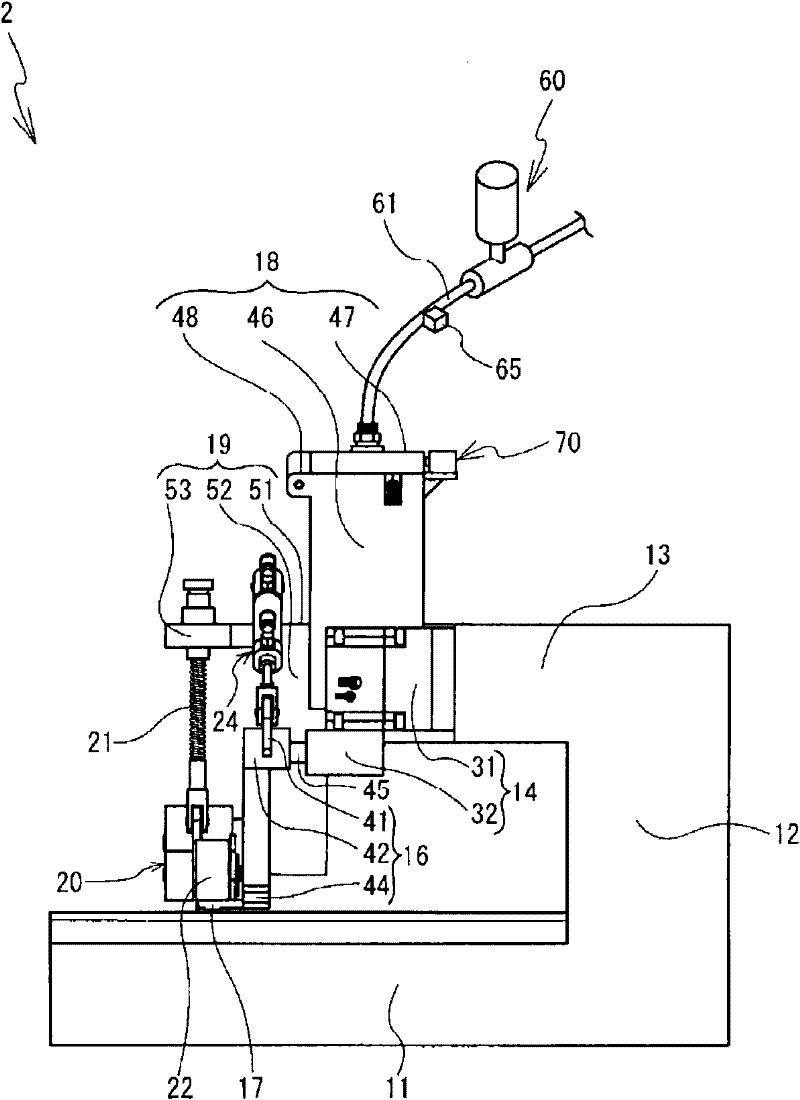

[0105] Next, a second embodiment will be described. The same symbols are assigned to the same structures as those in the first embodiment, and description thereof will be omitted.

[0106] refer to Figure 14 , the configuration of the cloth bonding apparatus 5 will be described. The cloth bonding device 5 includes a compressor 75 . The shape of the compressor 75 is substantially cylindrical with the vertical direction being the longitudinal direction. The compressor 75 is installed on the left side of the foot 212 of the table 220 . One end of the hose 61 is connected to the upper part of the compressor 75 . The other end of the hose 61 is connected to the cover 47 of the storage chamber 18 . The compressor 75 sends gas towards the storage chamber 18 through the hose 61 . The compressor 75 can supply gas pressure into the storage chamber 18 through the hose 61 . The CPU 201 can electrically control the operation of the compressor 75 .

[0107] The valve 60 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com