An Improved Structure of a Steam Generator

A technology of steam generator and steam outlet, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc. It can solve the problems of not being able to supply steam to users, affecting normal use of users, and not having enough heating elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

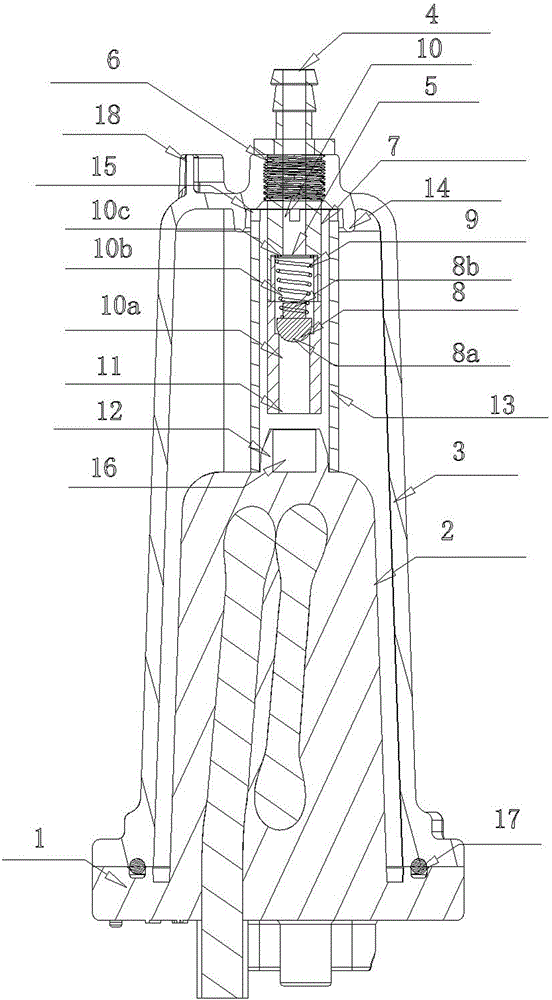

[0017] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0018] As shown in the figure, the present invention includes a columnar heating element 2 with a fixed base plate 1, a housing 3 that is set outside the columnar heating element 2 and fixed on the fixed base plate 1, and a sealing ring 17 is arranged between the housing 3 and the fixed base plate 1 The casing 3 is provided with a steam outlet 4 and a water injection port 18. The steam outlet 4 is located on the top of the casing 3. The special feature is that a valve 5 is connected under the steam outlet 4, and the valve 5 is threaded to seal the thread on the top of the casing 3. In the hole 6, the valve 5 includes a tubular body 7 made of copper, a piston 8 and a spring 9 arranged in the tubular body 7, and the passage 10 in the tubular body 7 includes A small-diameter channel 10a communicated with the inlet 11, a large-diameter channel 10b communicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com