Method for extracting citral from fruit of cubeb litsea tree

A technology of Litsea Cubeba and Litsea Cubeba Oil, applied in the direction of producing fat, essential oil/fragrance, etc., which can solve the problems of poor aroma, condensation, and poor benefit of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

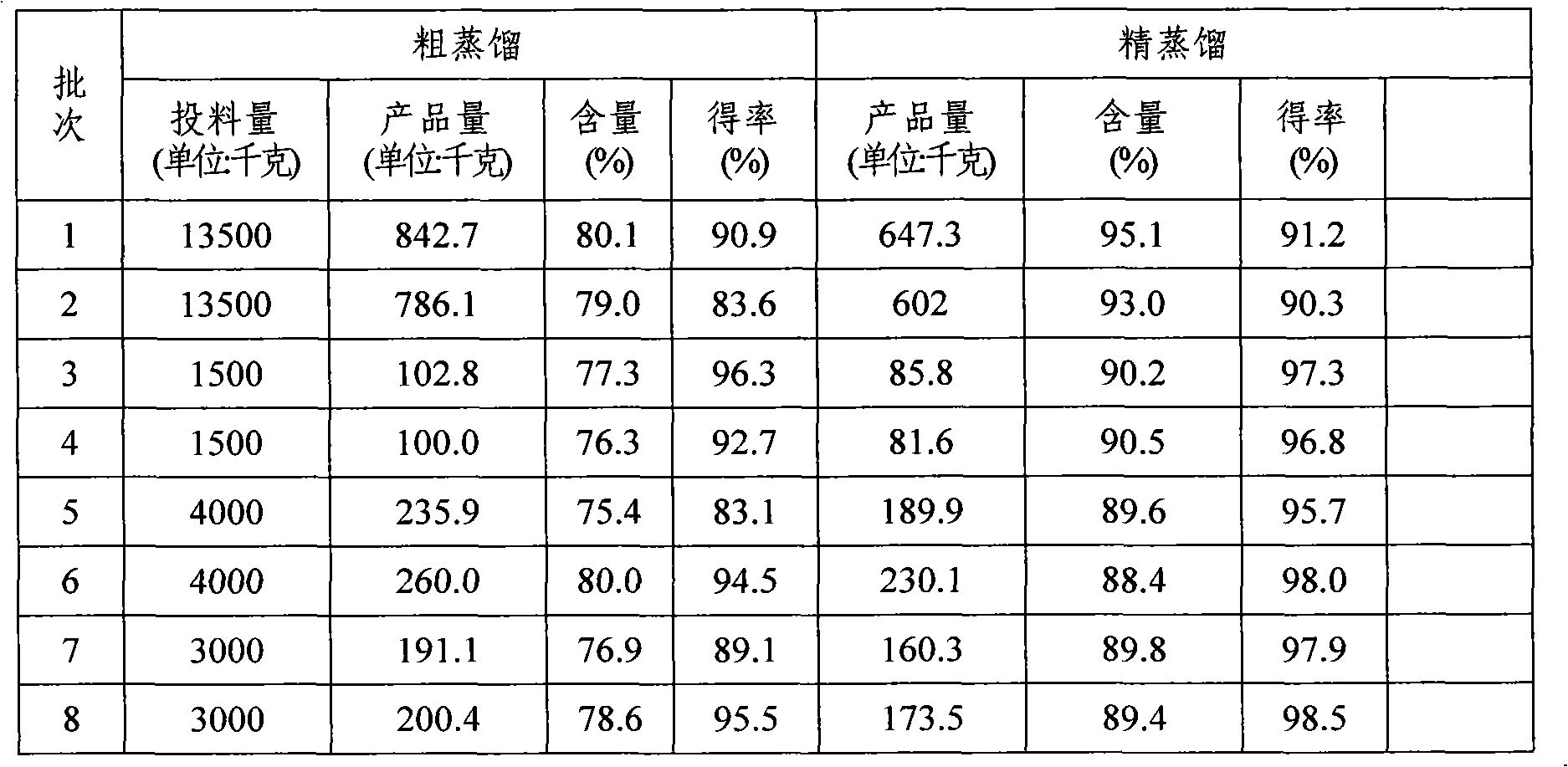

[0014] Put 13,500 kg of fresh Litsea cubeba fruits that have been cleaned and put into the crude extraction tank. In the steam, keep the pressure in the extraction tank at 0.1MPa; regularly draw a vacuum of about 0.06MPa. The steam containing litsea cubeba oil is introduced into the cooler to cool the oil-water-gas mixture to below 25°C. Oil-water liquid mixture is carried out oil-water separation, obtains 842.7 kilograms of 80.1% brown-yellow thick litsea cubeba oil. The crude litsea cubeba oil is introduced into the fine extraction tank, and the feeding amount does not exceed 75% of the volume of the fine extraction tank, and the litsea cubeba oil is extracted into steam, and the pressure in the extraction tank is kept at 0.1 MPa; the vacuum is regularly drawn at about 0.06 MPa. The steam containing litsea cubeba oil is introduced into the cooler, and the oil-water gas mixture is cooled to below 25°C; the oil-water liquid mixture is subjected to oil-water separation to obta...

specific Embodiment approach 2

[0015] Put 1,500 kg of fresh Litsea cubeba fruits that have been cleaned into the crude extraction tank, and the feeding amount does not exceed 75% of the volume of the crude extraction tank. Introduce steam into the crude extraction tank to distill the litsea cubeba fruit and bring the litsea cubeba oil into the In the steam, keep the pressure in the extraction tank at 0.1MPa; regularly draw a vacuum of about 0.06MPa. The steam containing litsea cubeba oil is introduced into the cooler to cool the oil-water-gas mixture to below 25°C. Oil-water liquid mixture is carried out oil-water separation, obtains 77.3% brown-yellow thick litsea cubeba oil 102.8 kilograms. The crude litsea cubeba oil is introduced into the fine extraction tank, and the feeding amount does not exceed 75% of the volume of the fine extraction tank, and the litsea cubeba oil is extracted into steam, and the pressure in the extraction tank is kept at 0.1 MPa; the vacuum is regularly drawn at about 0.06 MPa. ...

specific Embodiment approach 3

[0016] Put 4,000 kg of fresh Litsea cubeba fruits that have been cleaned and put into the crude extraction tank. In the steam, keep the pressure in the extraction tank at 0.1MPa; regularly draw a vacuum of about 0.06MPa. The steam containing litsea cubeba oil is introduced into the cooler to cool the oil-water-gas mixture to below 25°C. Oil-water liquid mixture is carried out oil-water separation, obtains 235.9 kilograms of 75.4% brown-yellow thick litsea cubeba oil. The crude litsea cubeba oil is introduced into the fine extraction tank, and the feeding amount does not exceed 75% of the volume of the fine extraction tank, and the litsea cubeba oil is extracted into the steam, and the pressure in the extraction tank is kept at 0.1 MPa; the vacuum is regularly drawn at about 0.06 MPa. The steam containing litsea cubeba oil is introduced into the cooler, and the oil-water gas mixture is cooled to below 25°C; the oil-water liquid mixture is subjected to oil-water separation to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com