Antibacterial ultra-filtration membrane and preparation method thereof

A technology of ultrafiltration membrane and membrane casting solution, which is applied in the field of membrane materials, can solve the problem that litsea cubeba oil cannot be released in a long-term and sustained manner, and achieve the effect of prolonging the effective antibacterial time and preventing rapid volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

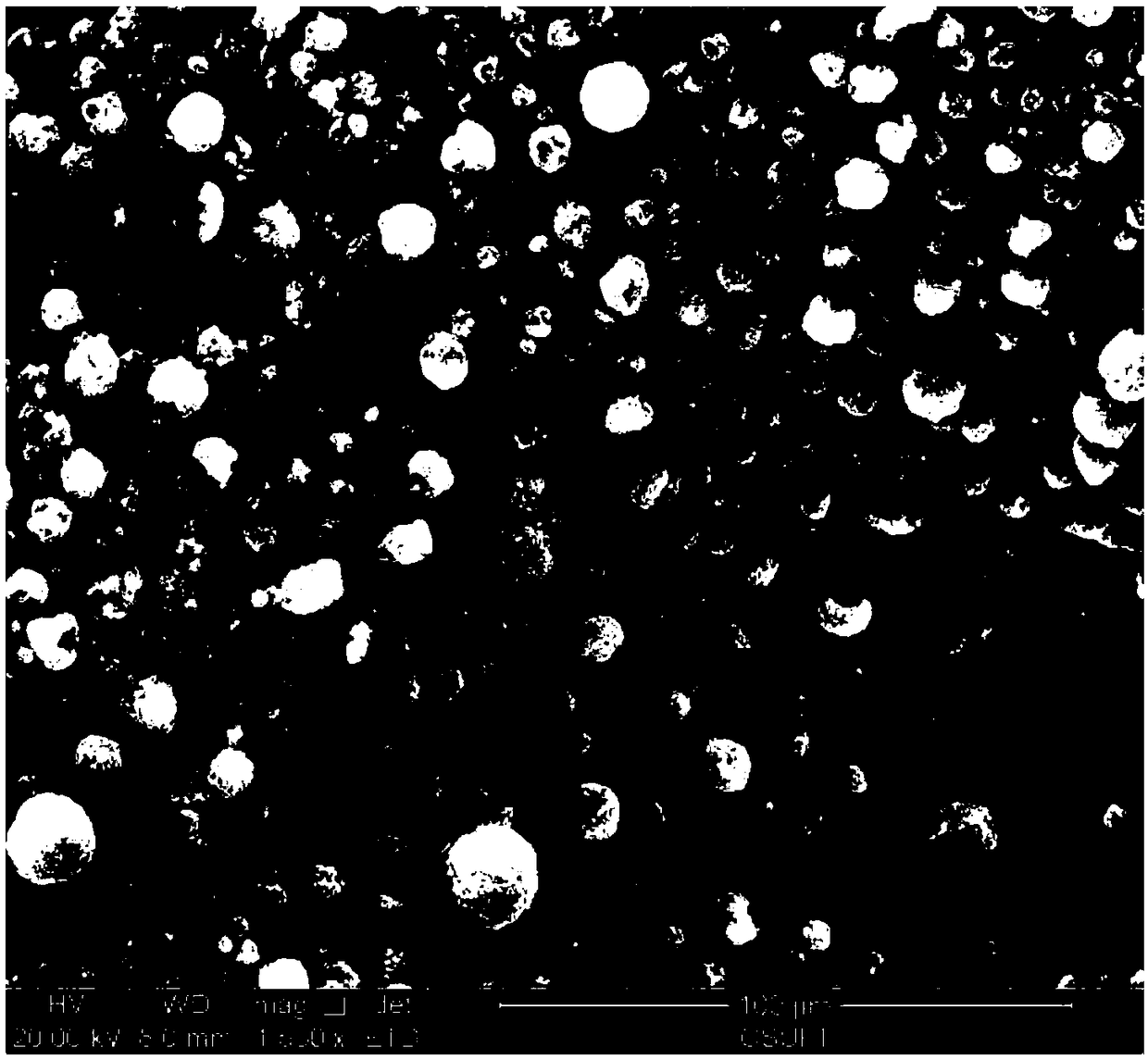

[0040] The preparation method of the litsea cubeba oil microcapsules in embodiment 1-3 is as follows:

[0041] T1, configure the gum arabic solution: dissolve the gum arabic powder in water, and configure the gum arabic solution with a concentration of 4%;

[0042] T2. Prepare hydroxypropyl-β-cyclodextrin solution: dissolve hydroxypropyl-β-cyclodextrin in water, and configure a 4% hydroxypropyl-β-cyclodextrin solution;

[0043] T3, stirring and mixing: mix the gum arabic solution and the hydroxypropyl-β-cyclodextrin solution in a ratio of 1:2, add Litsea cubeba oil in a ratio of 1:3 to the core wall under stirring, and stir until the mixture is uniform. Obtain an emulsion;

[0044] T4. High-pressure homogeneous emulsification: homogenize the mixed emulsion for 12 minutes under a pressure of 500 bar;

[0045] T5, spray drying: at the inlet wind speed of 80%, the feed pump speed of 15%, and the inlet temperature of 170°C, the mixed emulsion is spray-dried, and the litsea cubeb...

Embodiment 1

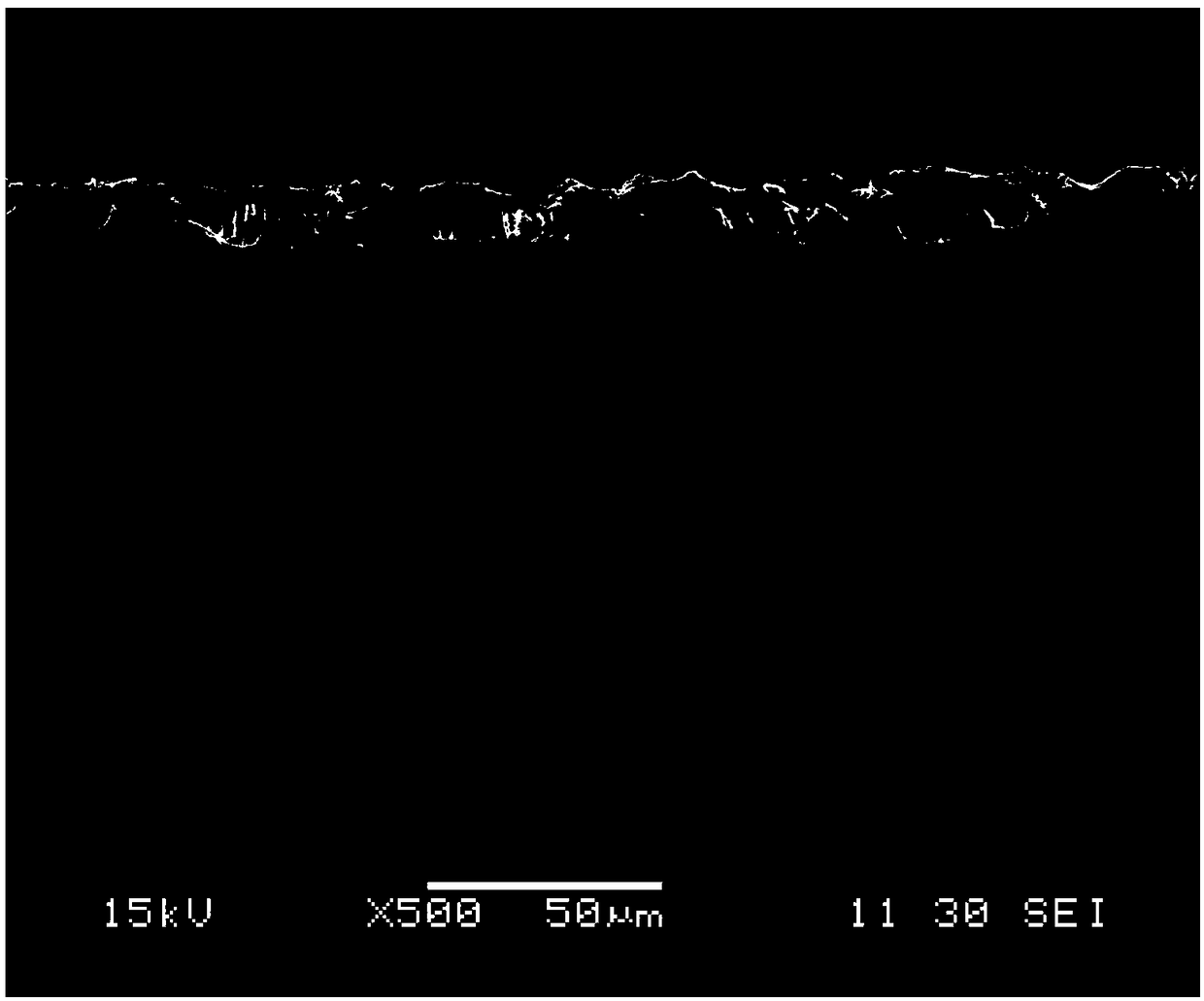

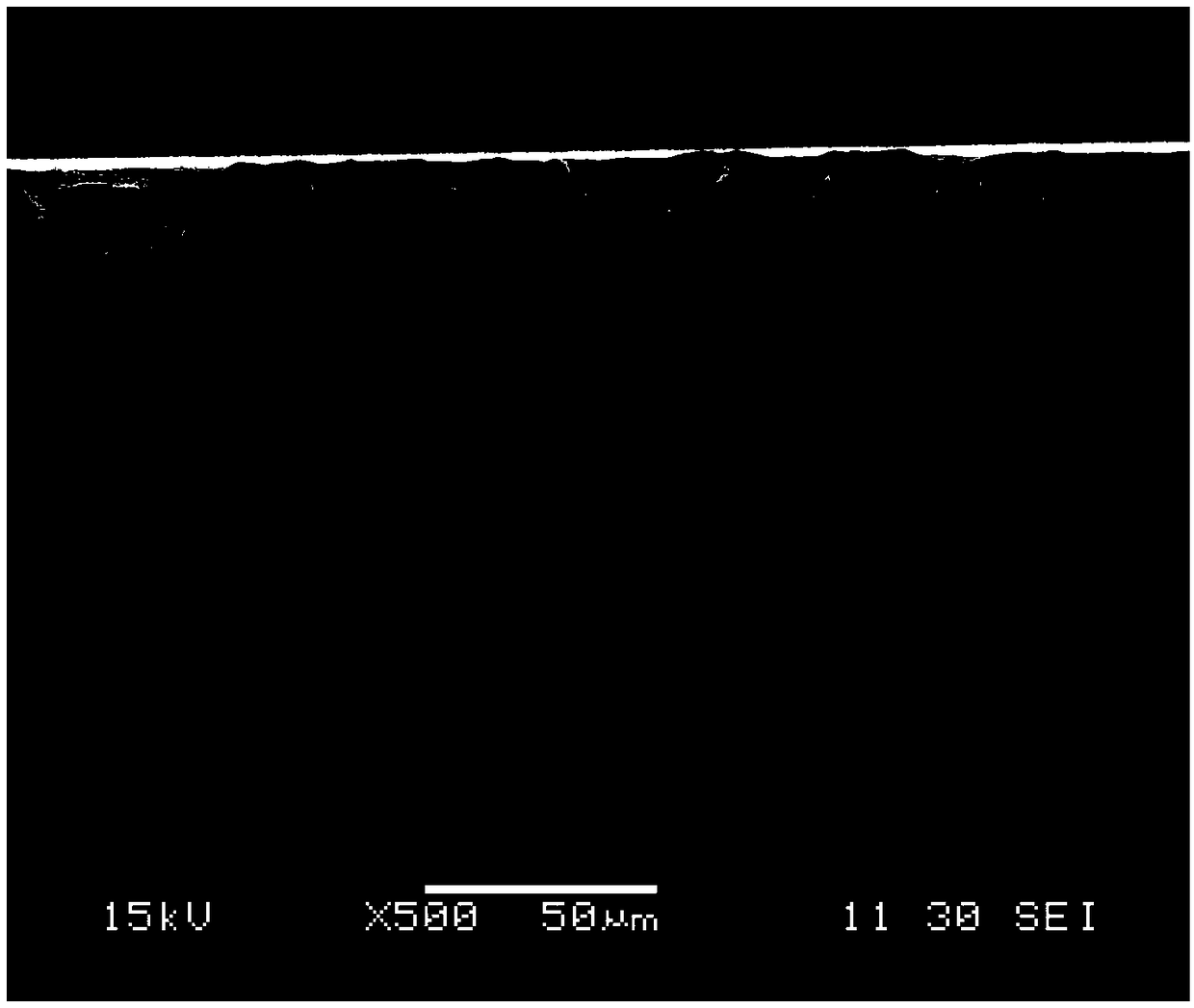

[0047] Each component prepares the casting solution of the bacteriostatic ultrafiltration membrane according to the following weight ratio: 13 parts of PES, 10 parts of polyvinylpyrrolidone, 5 parts of PEG4005, 2 parts of litsea cubeba oil microcapsules, 70 parts of N-methyl-2-pyrrolidone , put the above materials into a three-necked flask, control the heating temperature to 50°C, stir at a stirring speed of 300r / min for 8h, and then place it in a vacuum oven at 25°C for 6h to remove air bubbles and form a uniform and transparent casting solution. Under the condition that the temperature is 25°C and the humidity is 70%, the casting solution is cast on a clean glass plate, and the film scraping machine is used to scrape the film on the cast glass plate to obtain the casting solution containing a thickness of 0.5mm. Glass plate; volatilize the glass plate in the air for 10 seconds, and then immerse it in the coagulation bath for 6 hours to obtain the detached bacteriostatic ultra...

Embodiment 2

[0049]Each component prepares the casting solution of the bacteriostatic ultrafiltration membrane according to the following weight ratio: 13 parts of PES, 10 parts of polyvinylpyrrolidone, 5 parts of PEG4005 parts, 4 parts of litsea cubeba oil microcapsules, 68 parts of N-methyl-2-pyrrolidone . Put the above materials into a three-necked flask, control the heating temperature to 50°C, stir at a stirring speed of 300r / min for 8h, and then place it in a vacuum oven at 25°C for 6h to remove air bubbles and form a uniform and transparent casting solution. Under the condition that the temperature is 25°C and the humidity is 70%, the casting solution is cast on a clean glass plate, and the film scraping machine is used to scrape the film on the cast glass plate to obtain the casting solution containing a thickness of 0.5mm. Glass plate; volatilize the glass plate in the air for 10 seconds, and then immerse it in the coagulation bath for 6 hours to obtain a detached bacteriostatic u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com