Ultrahigh strength cold rolled steel strip for automobile seat

An ultra-high-strength, cold-rolled steel strip technology, applied in the field of ultra-high-strength cold-rolled steel sheets, can solve problems such as inapplicability, and achieve excellent flanging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

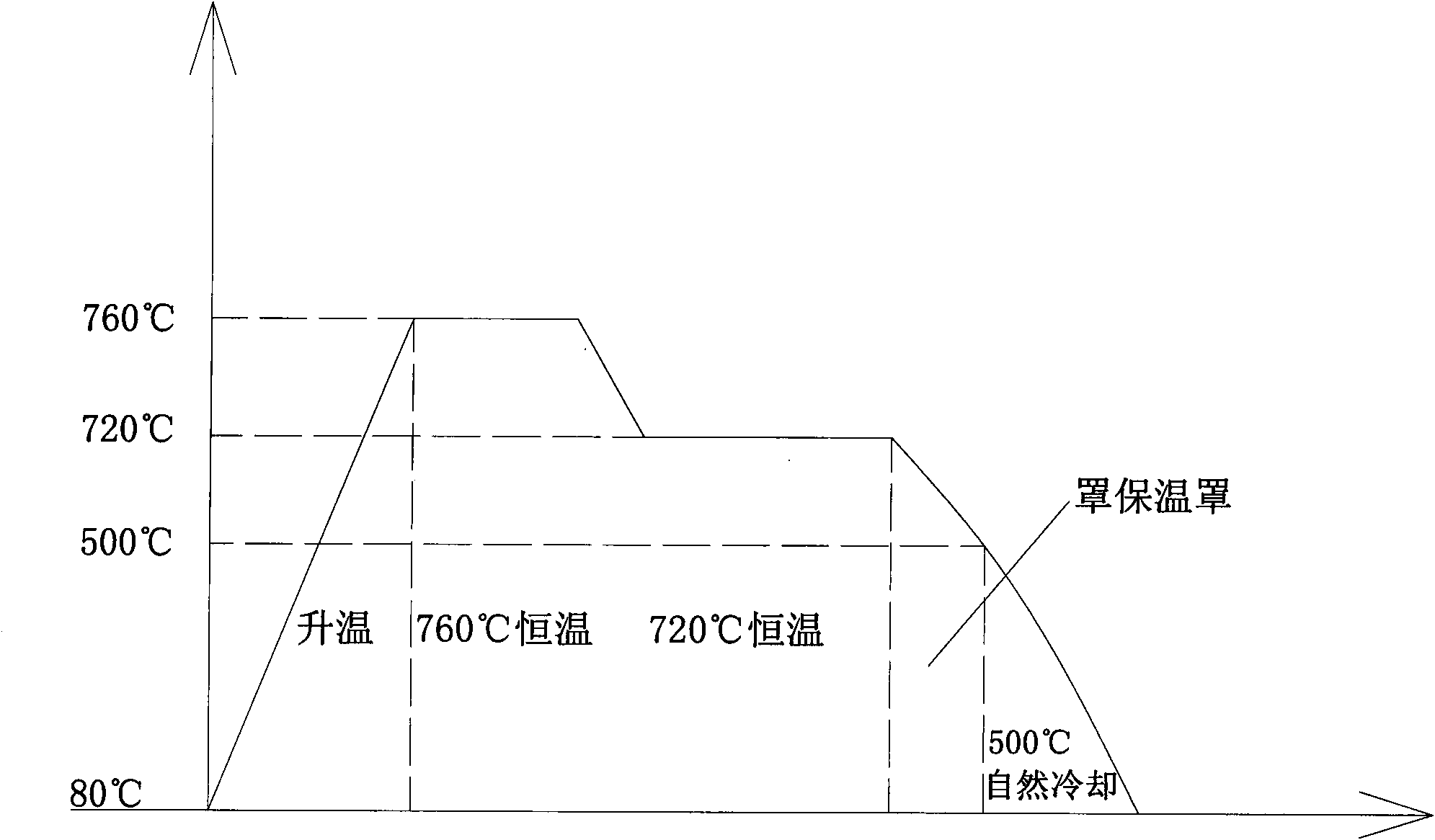

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0015] The effect of each element of the present invention is as follows:

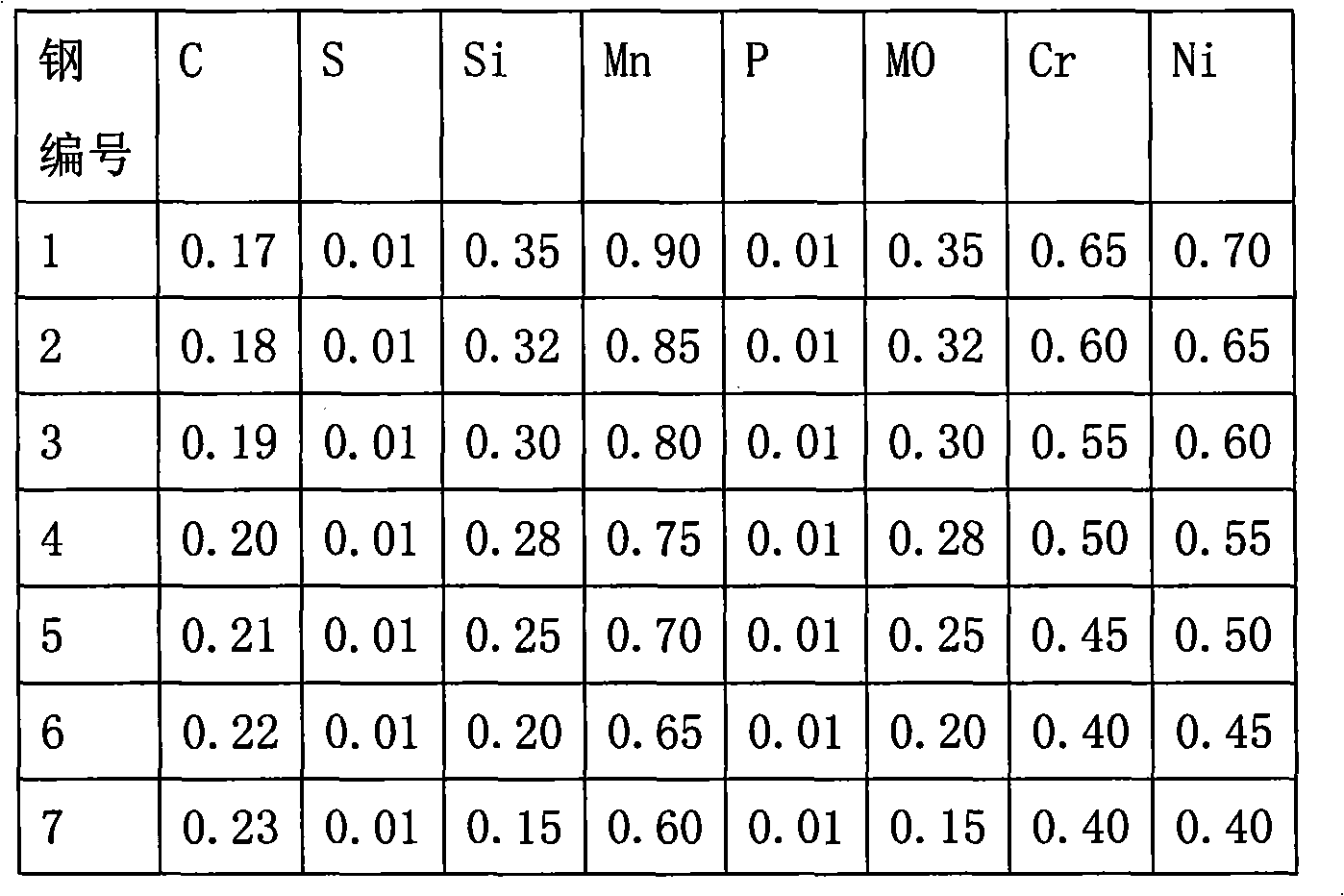

[0016] C: In order to make the tensile strength 350-550 MPa, it can be adjusted appropriately according to the contents of Mn, Cr, and Mo. However, if C is less than 0.17%, the cost of steelmaking will increase, and if it exceeds 0.23%, the tensile strength will exceed 550 MPa regardless of the content of Mn, etc., so C is set at 0.17-0.23%.

[0017] Si: Si is an element that increases the transformation point of Ar3, and it is desirable to reduce the Si content as much as possible. If Si exceeds 0.35%, it is difficult to obtain a single-phase martensitic structure of 350-550 MPa, so Si is set at 0.15-0.35%.

[0018] P: P is added to adjust the strength, and if it exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com