Device and method for monitoring corrosion of buried steel pipelines

A corrosion monitoring and pipeline technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, current density measurement, etc., can solve problems such as cross point induction corrosion, failure to test, corrosion perforation, etc., and achieve the effect of avoiding wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below in conjunction with accompanying drawing.

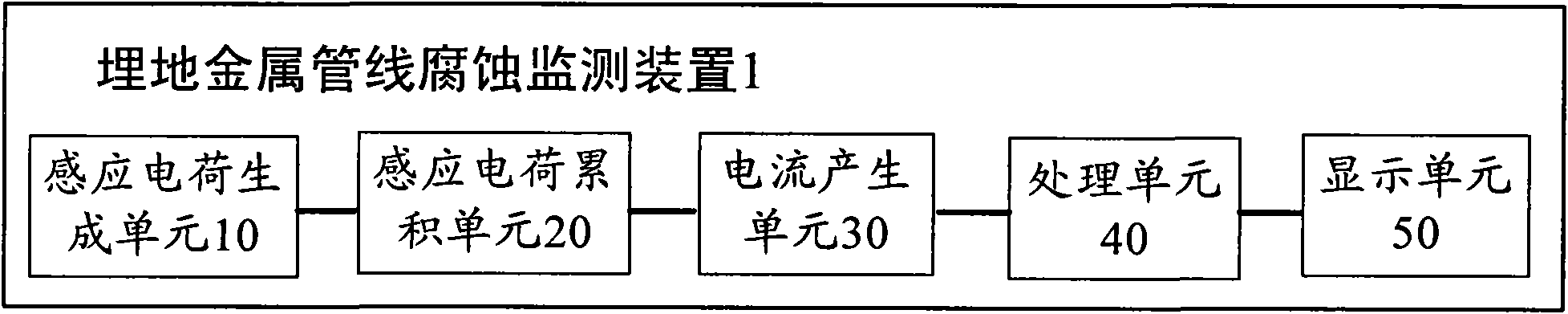

[0028] figure 1 It is a block diagram of an embodiment of the buried metal pipeline corrosion monitoring device 1 according to the present invention. Such as figure 1 As shown, the buried metal pipeline corrosion monitoring device 1 includes an induced charge generation unit 10 , an induced charge accumulation unit 20 , a current generation unit 30 , a processing unit 40 and a display unit 50 connected in sequence.

[0029]Wherein the induced charge generating unit 10 is used to generate induced charges, which are buried in the soil near the pipeline to be monitored, preferably directly above the pipeline and 1-2 cm away from the pipeline. The induced charge generating unit 10 is in the same electromagnetic field environment as the pipeline to be monitored, and it includes a metal rod with an insulating layer on the surface, and the metal rod will generate induced charges in the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com