Pipeline corrosion monitoring device based on array type piezoelectric film sensor

A piezoelectric film and corrosion monitoring technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of data recording confusion, unfavorable long-term monitoring of pressure pipelines, complex and cumbersome single-point detection operations, etc., to avoid measuring equipment and realize regional monitoring functions , The effect of improving the efficiency of corrosion detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

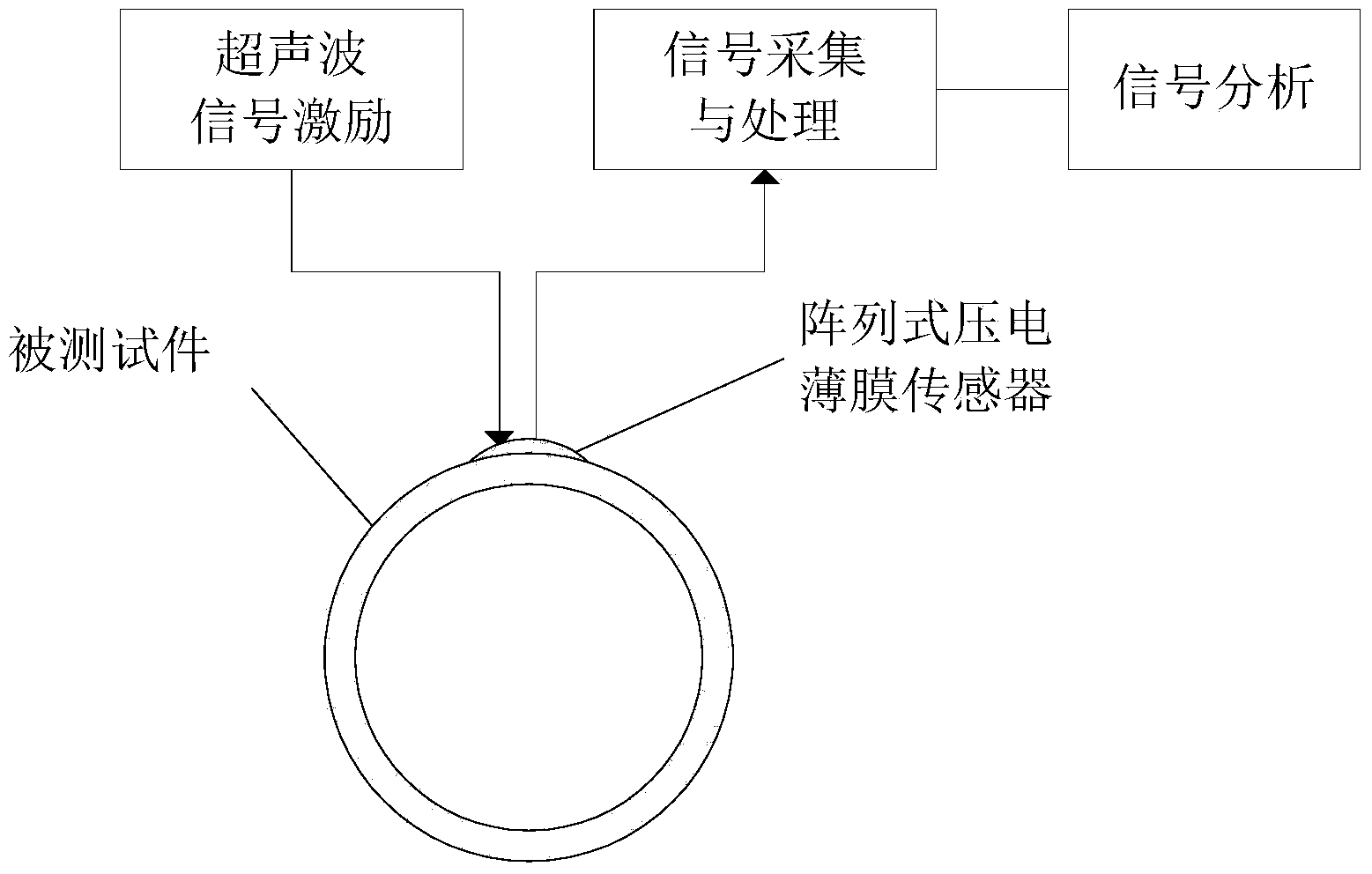

[0014] The invention provides a pipeline corrosion monitoring system based on an array piezoelectric thin film sensor. The system includes an ultrasonic signal excitation module, an array piezoelectric thin film sensor module, a signal acquisition and processing module and a signal analysis module. Among them: the ultrasonic signal excitation part controls the pulse signal generator to send out periodic narrow pulses, which are loaded on the array piezoelectric film sensor probe. The probe is excited to generate ultrasonic waves, and the ultrasonic waves will be reflected back and forth on and below the test piece for many times. These reflected waves are received by the piezoelectric probe to form electrical signals, and after signal acquisition and processing through amplification, filtering, multi-channel scanning, etc., the signal analysis module cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com