Moss clearing conveyor

A technology of clearing machine and moss, which is applied in the field of clearing machine, can solve the problems of waste of manpower and material resources, slow clearing speed, etc., and achieve the effect of thorough clearing, convenient operation and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

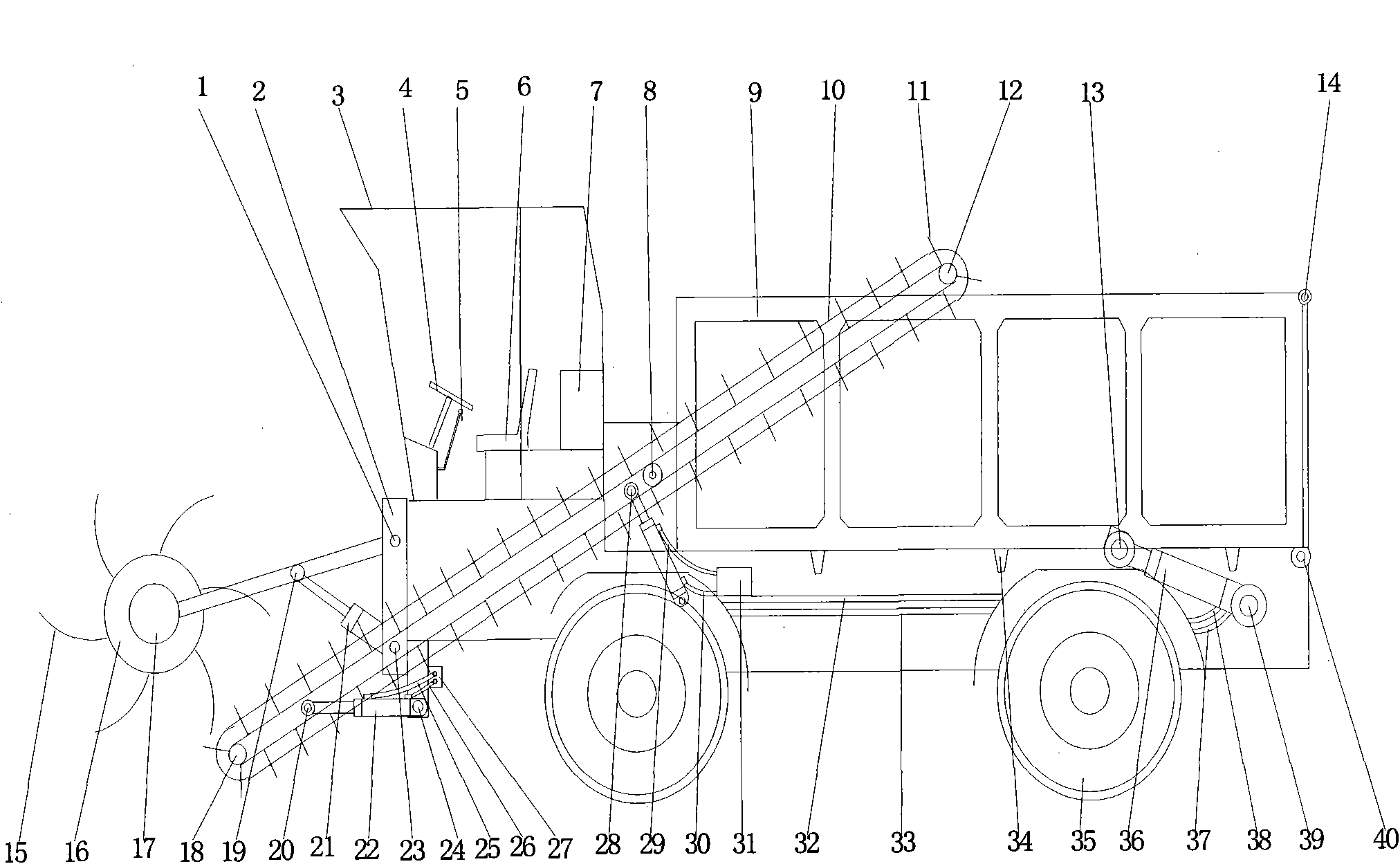

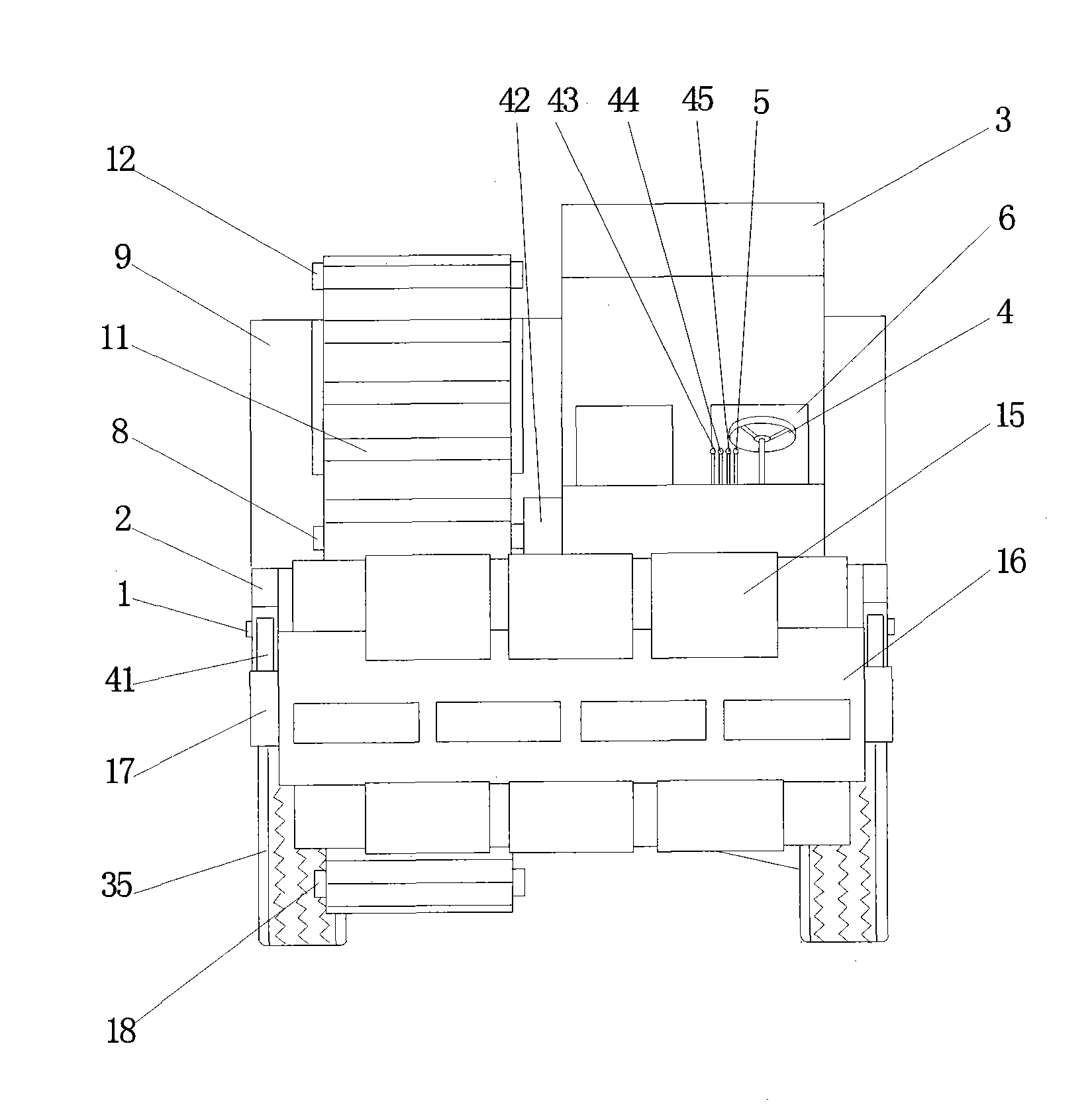

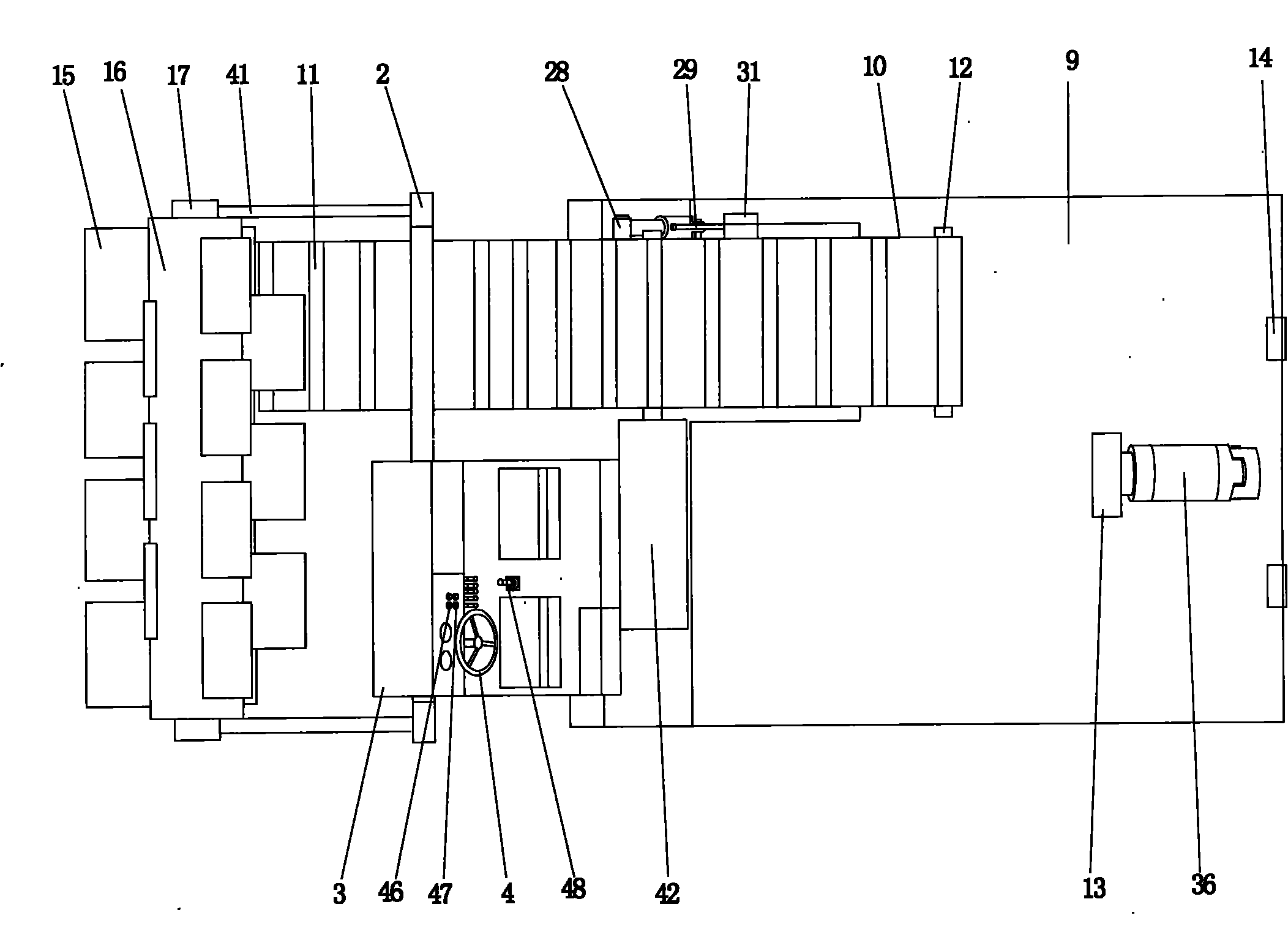

[0011] A moss removal machine, mainly composed of a cab, a scraper shaft, a hydraulic valve, a hydraulic cylinder, a conveyor belt, etc., is characterized in that the motor (17) connected to the frame (2) is fixed by a pin shaft (1) On the bracket (41), when the driver presses the switch (46), the motor (17) drives the scraper shaft (16) to rotate, and the scraper (15) mounted on the scraper shaft (16) rotates accordingly The moss is scraped to one end of the conveyor belt (10), and at the same time the driver presses the switch (47), and the motor (42) rotates to drive the drive shaft (8) connected thereto, and the drive shaft (8) rotates to drive the drive shaft (8) installed on the The passive shafts (12) and (18) at both ends of the conveyor belt (10) rotate, and at this time the conveyor plate (11) installed on the conveyor belt (10) also rotates at the same time, and the moss is sent into the conveyor belt by the scraper shaft (16). plate (11), and then conveyed to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com