Anti-theft lock core

A technology of anti-theft lock cylinders and cylinders, which is applied in construction locks, cylinder locks, locks with rotating keys, etc., can solve the problems of poor anti-theft performance, improve anti-theft performance, enhance safety, and prevent damage to locks core effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

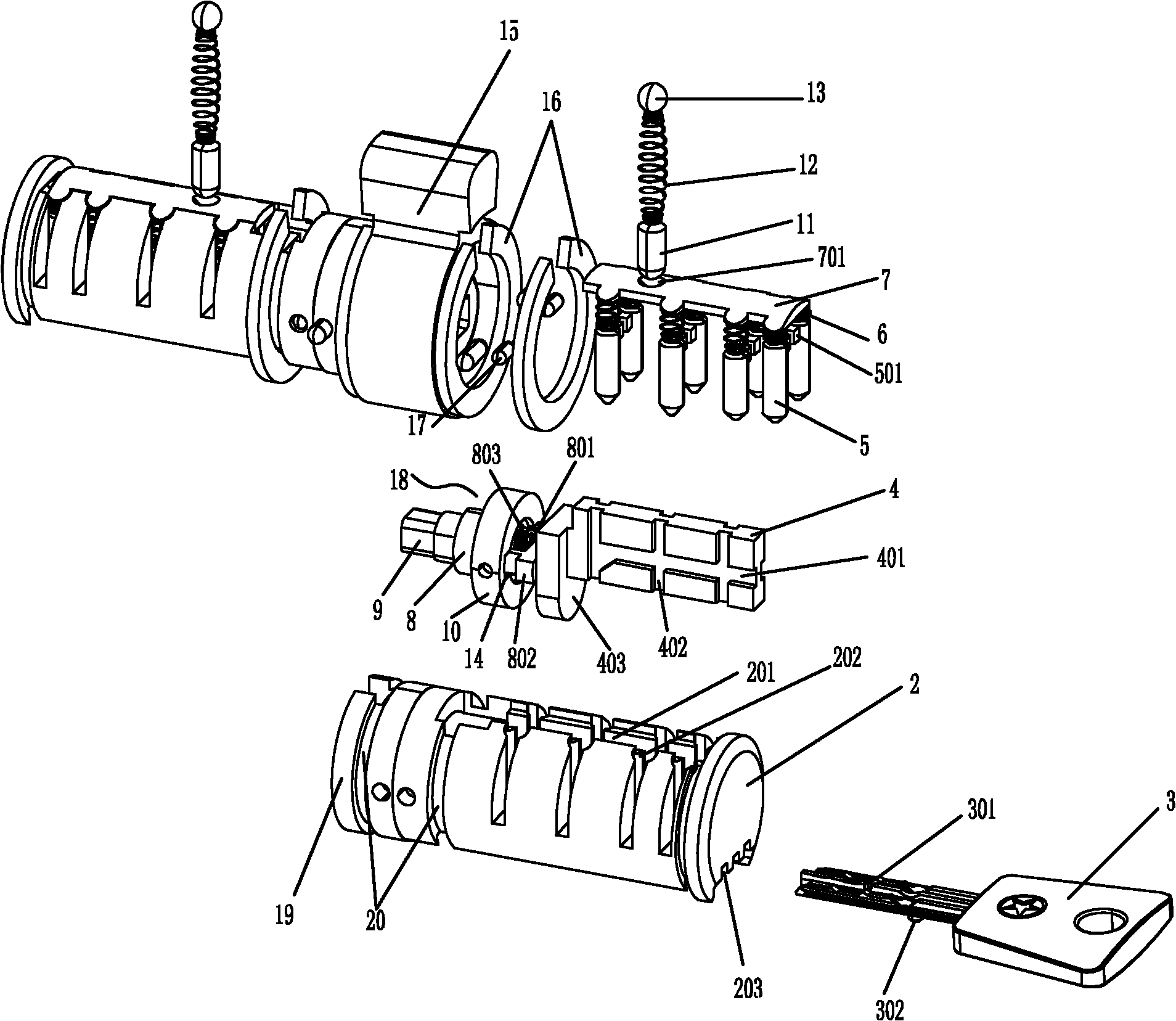

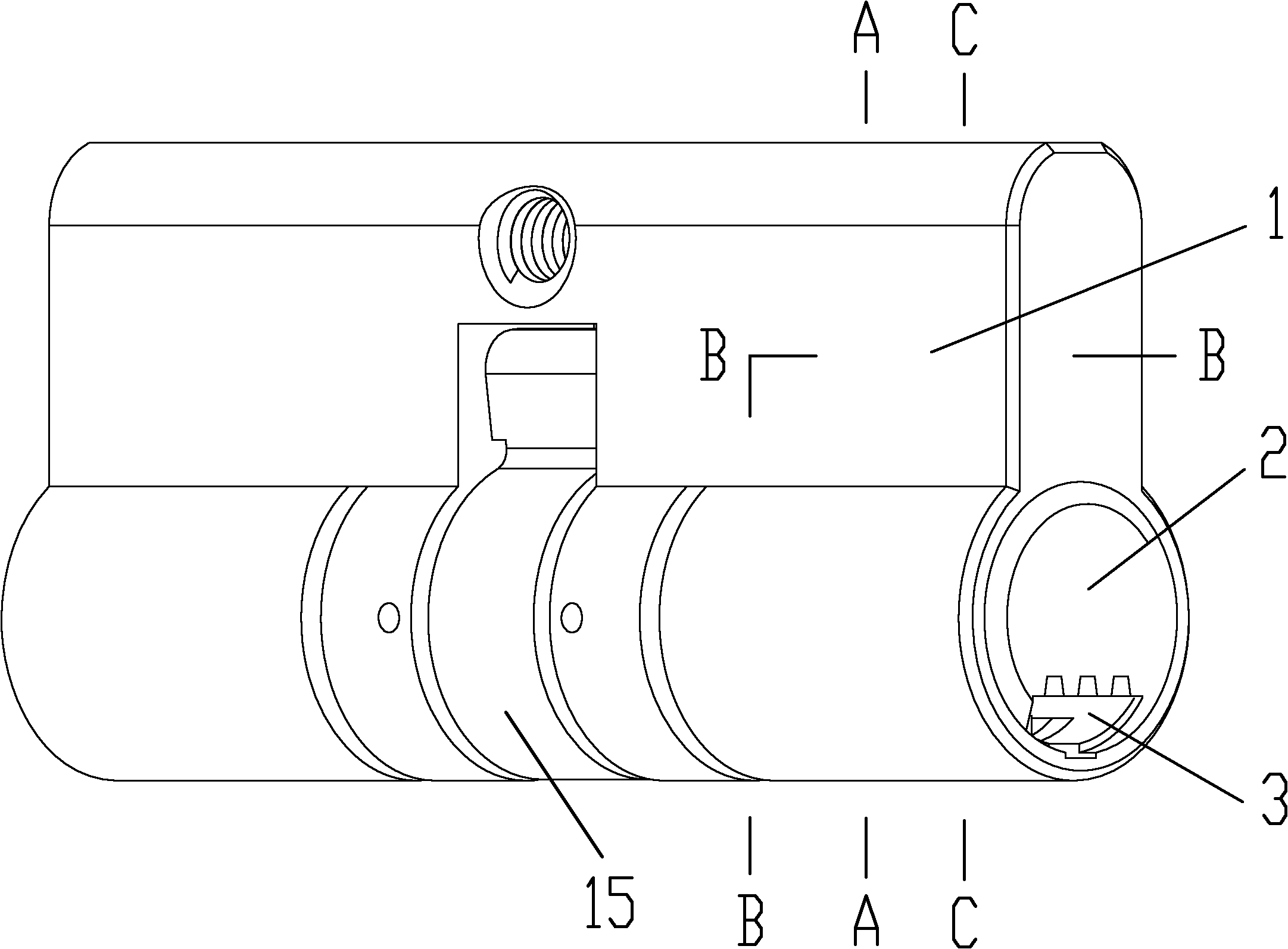

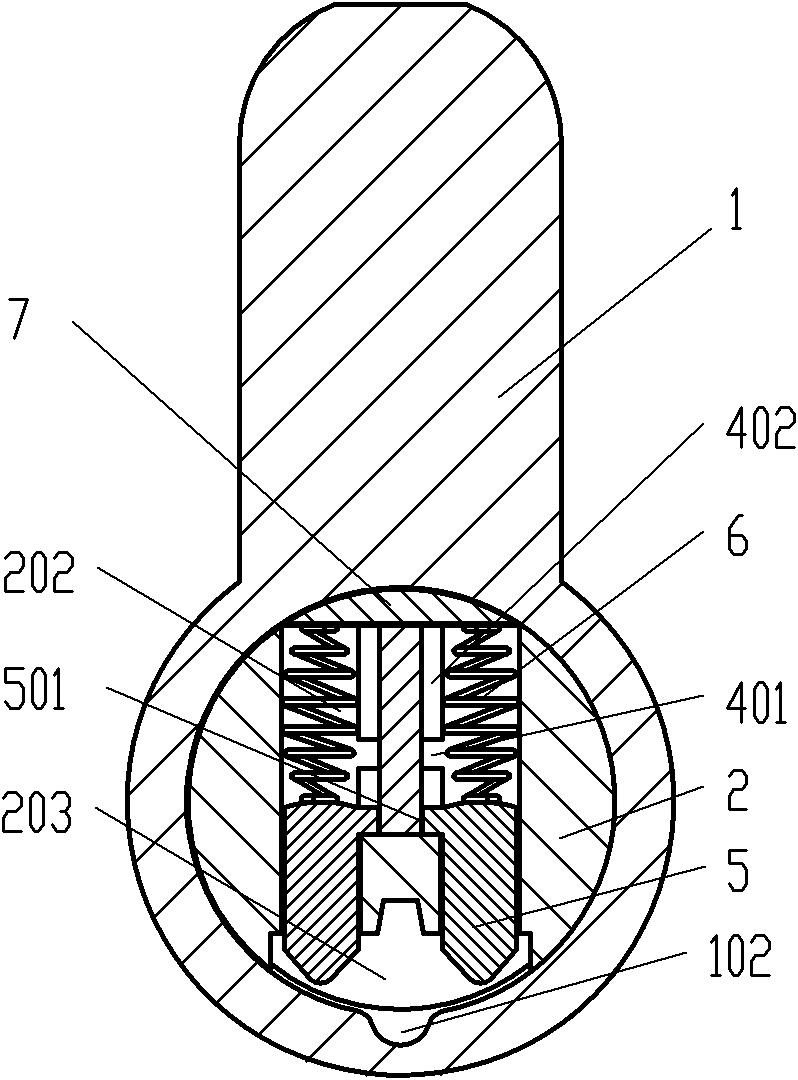

[0021] Such as figure 1 , figure 2 The shown anti-theft lock cylinder is mainly composed of a mandrel 9, a dial 15 installed in the center of the mandrel 9, a key 3, a lock cylinder shell 1 and a lock cylinder 2 with a key hole 203. To form left and right two rows of pinholes 202 that are symmetrical and communicate with the keyhole 203, each pinhole 202 is provided with a bullet post 5 and a pressing spring 6 from bottom to top. The top of the arc-shaped briquetting block 7 is set, and the briquetting block 7 is offset against the inner wall of the cylinder housing 1. A slider groove 201 is formed between the two groups of pinholes 202, and a slider 4 that can move axially along the lock cylinder 2 is installed in the slider groove 201, and the two side walls of the slider 4 are provided with holes that communicate with the pinholes 202. The longitudinal track groove 402 and the transverse track groove 401 , the upper part of the bullet 5 forms a bump 501 , and the bump 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com