Production method of light scattering film, light scattering film, polarizing plate, image display device, and transmissive/semi-transmissive liquid crystal display device

A light-scattering film and solution technology, applied in the identification device, polarizing element, optics, etc., can solve the problems of narrowing the distance between the light source and the diffusing sheet, and difficult to diffuse light by conventional diffusing films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

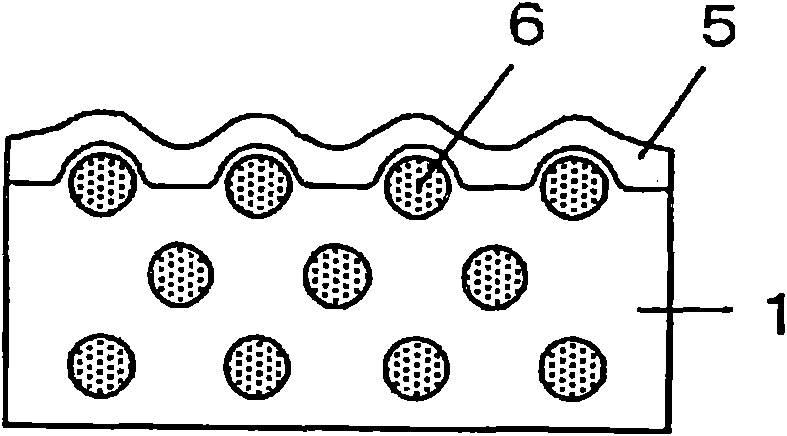

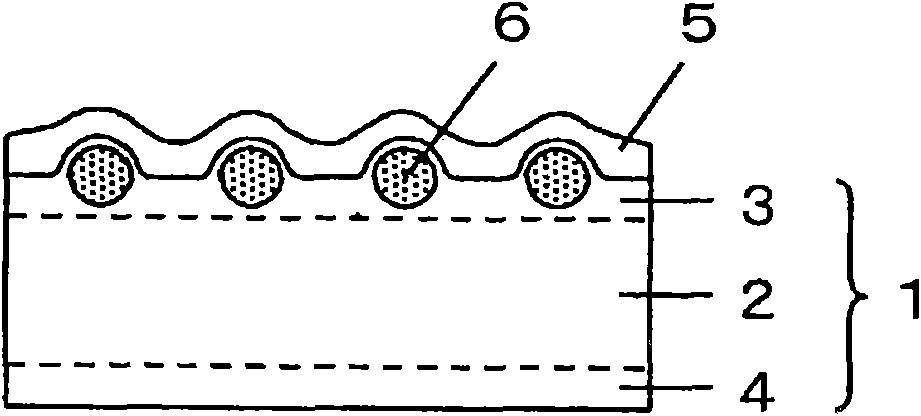

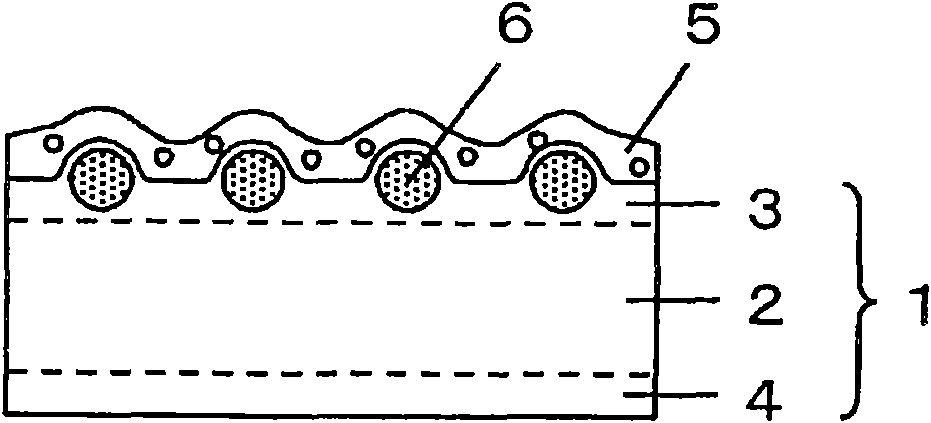

[0085] The light-scattering film according to an exemplary embodiment of the present invention causes neither reduction in brightness of forward white light nor moire fringes, especially when it is used as a protective film of a polarizing plate on the backlight side of a liquid crystal display device, Capable of providing image display with highly uniform brightness.

[0086] Next, exemplary embodiments of the present invention will be described, but the present invention is not limited to them. In the specification, when a numerical value represents a physical property value, characteristic value, etc., the term "from (numerical value 1) to (numerical value 2)" means "(numerical value 1) or greater but not greater than (numerical value 2) ". The term "(meth)acrylate" as used herein means at least one of acrylate and methacrylate. This also applies to "(meth)acrylic" or "(meth)acryloyl".

[0087] The present invention relates to a light-scattering film having light-scatter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com