Wind-radiating vehicular fuel cell

A technology of fuel cells and fuel cell stacks, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., and can solve the problems of poor heat dissipation on the outer package surface of fuel cells, adding additional heat sinks, increasing weight and cost, etc. , to achieve the effect of realizing commercial application, strong external package, and reducing heat dissipation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

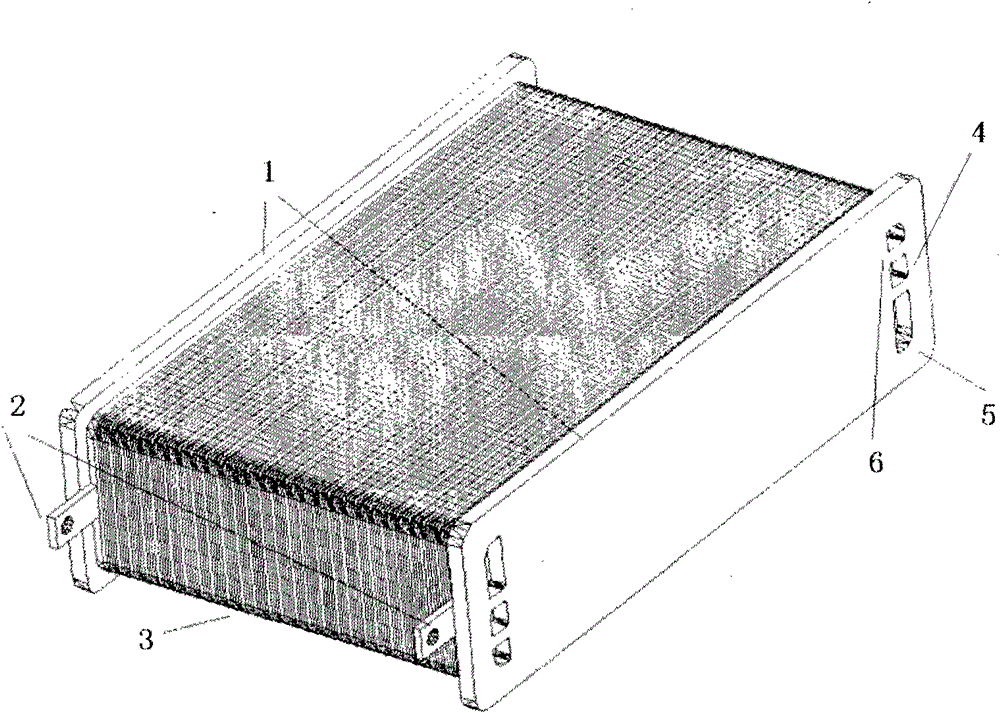

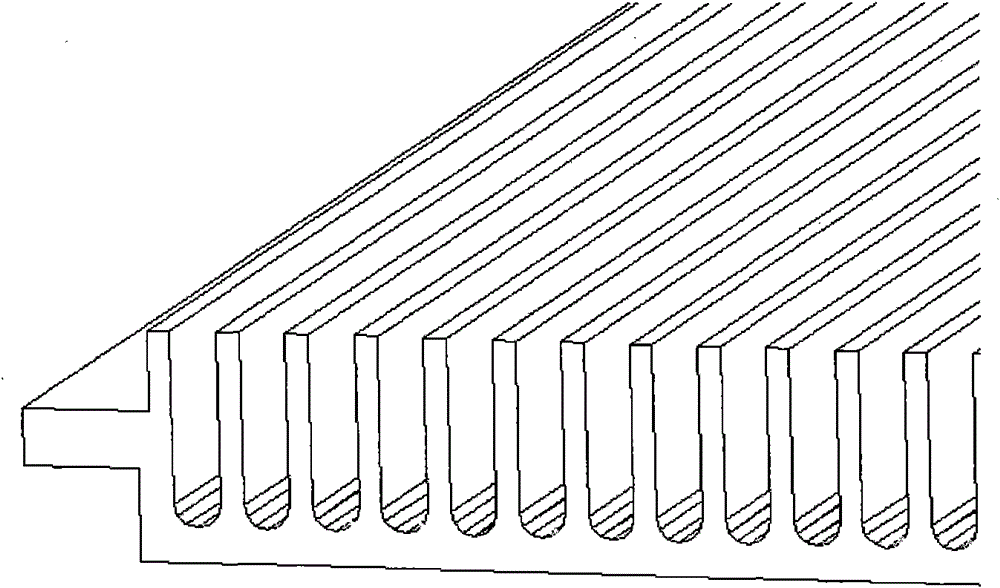

[0024] The embodiment shown in the drawings is a 15kW fuel cell stack for vehicles, which is composed of a non-conductive end plate 1, a metal bipolar plate 3, and a current collector plate 2. The side of the end plate 1 is provided with an air inlet and outlet 5, a hydrogen inlet and outlet 6, and Auxiliary cooling water inlet and outlet 4. The effective area of the battery is 360 square centimeters, the number of battery cells is 120, and the current density is 500 mA per square centimeter. Use the end plate 1, metal bipolar plate 3 and collector plate 2 of the fuel cell of the prior art to assemble the fuel cell stack, keep the shape of each plate unchanged, and keep the inlet and outlet 4 of the heat dissipation water, so that it can meet the needs of natural heat dissipation. When the heat dissipation of the whole vehicle is required, it is used as an auxiliary heat dissipation. The outer surface of the fuel cell outer package 7 is provided with finned heat sinks. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com