Method for fitting an equipping device

An assembly device and equipment technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

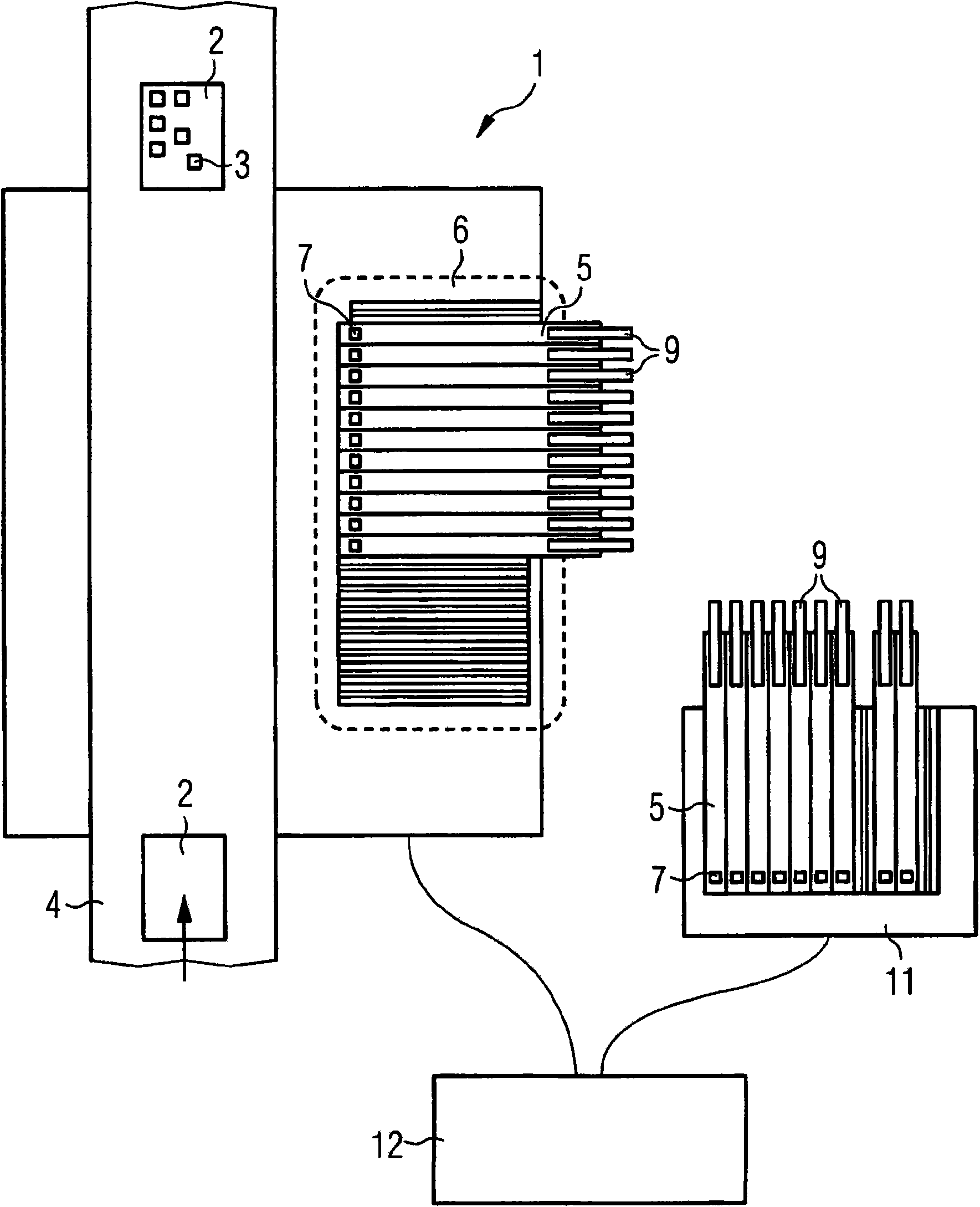

[0035] figure 1 A schematic plan view of the assembly device 1 is shown schematically, which in this embodiment is shown as a separate automatic assembly machine. However, it is also possible for the assembly device 1 to have a plurality of individual machines in a production line. The assembly device 1 is used for assembling components 3 on the substrate 2 . The substrate 2 is transported via the transport path 4 into the assembly area of the assembly device 1 , where it is mounted with components 3 . Components 3 are supplied into a supply area 6 by means of a supply device 5 at a defined pick-up position 7 for picking. The picking up of the components 3 and the mounting of the substrate 2 can take place, for example, by means of a movable mounting head (not shown). The assembled substrate 2 is conveyed out of the assembly area of the assembly device 1 through the conveying path 4 .

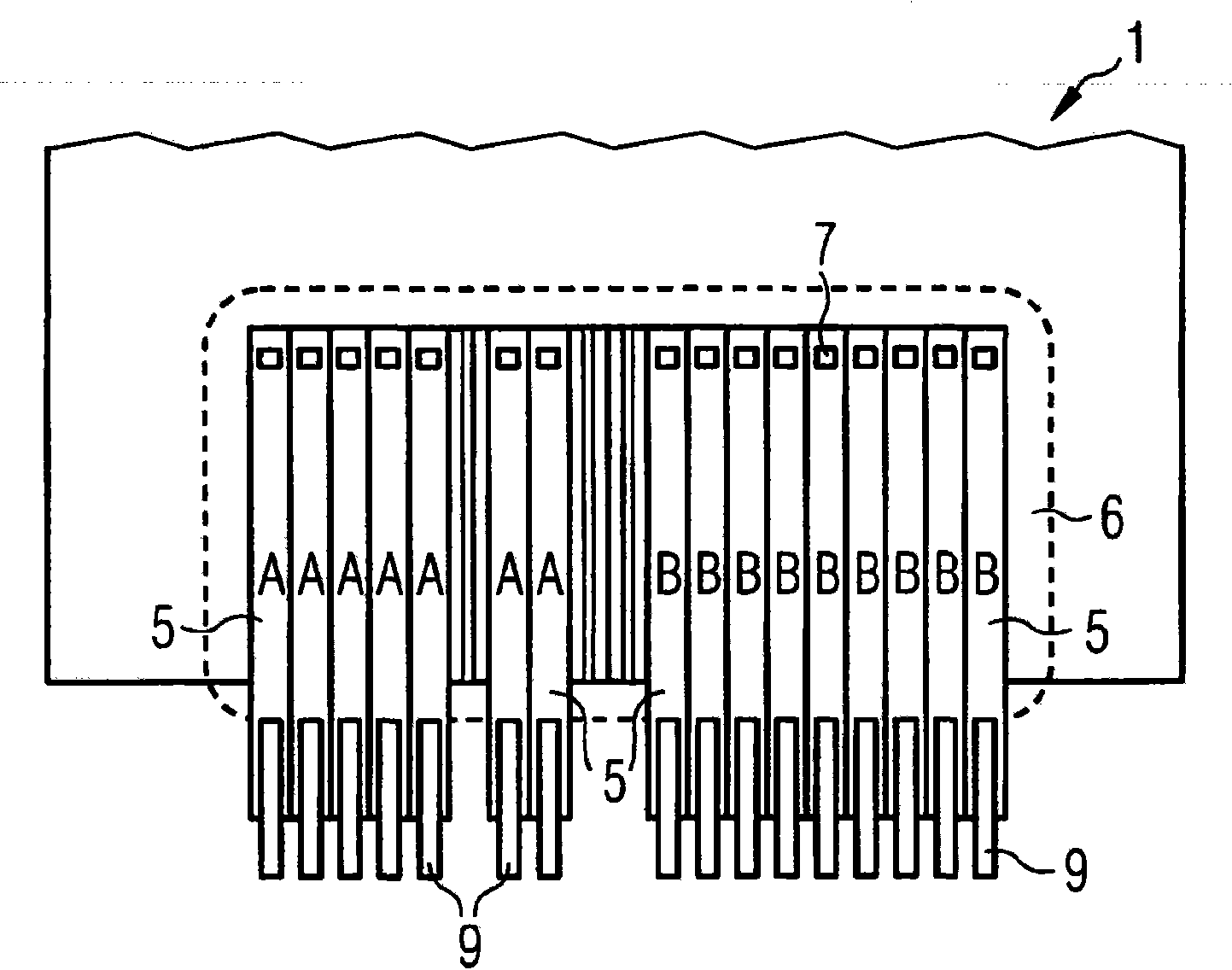

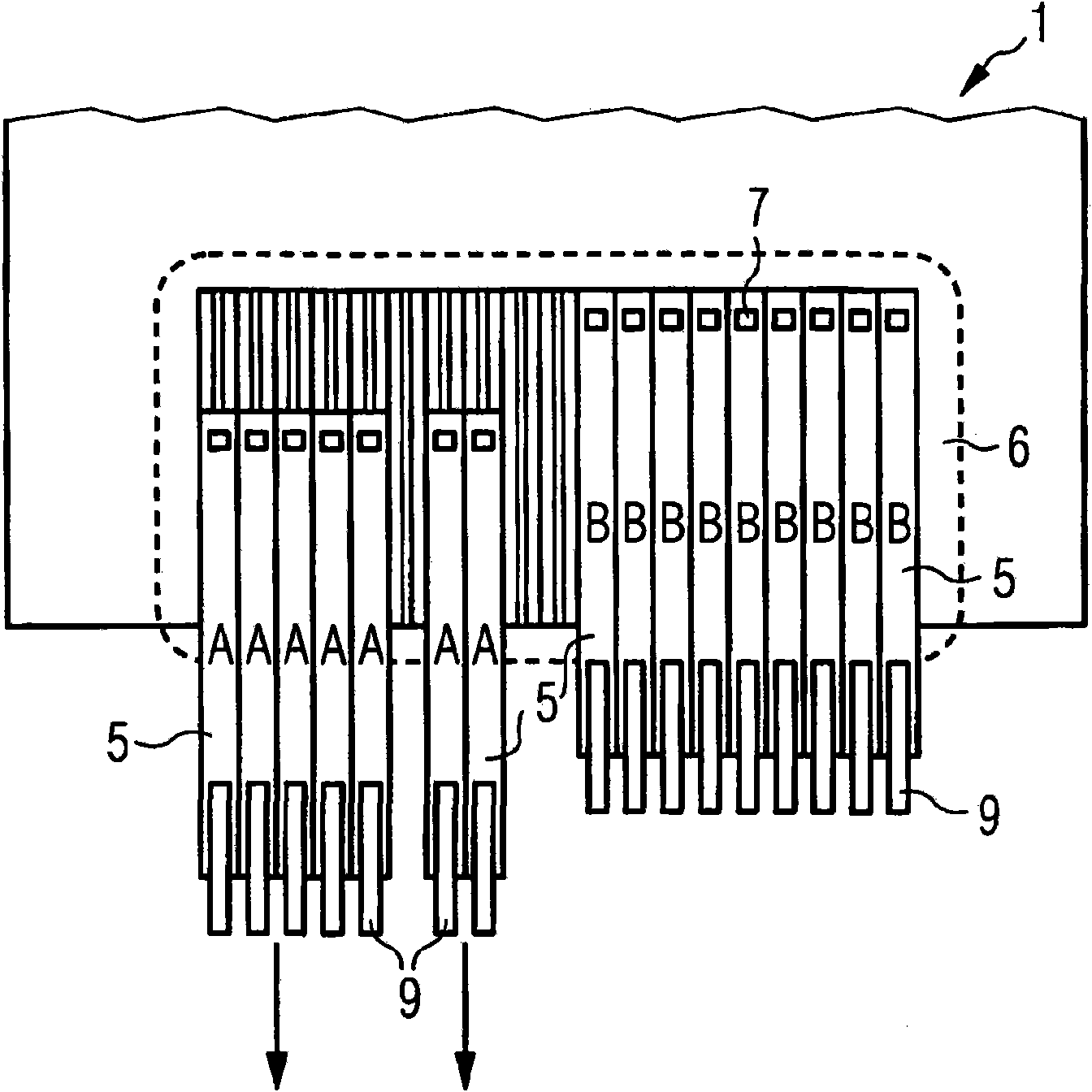

[0036] A defined number of supply devices 5 for different component types can be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com