Vehicle hydraulic mechanical transmission system for mine

A technology of hydraulic machinery and transmission system, which is applied in the field of vehicle transmission system, can solve the problems of high risk, large investment, and high price of imported models, and achieve the effect of good reliability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

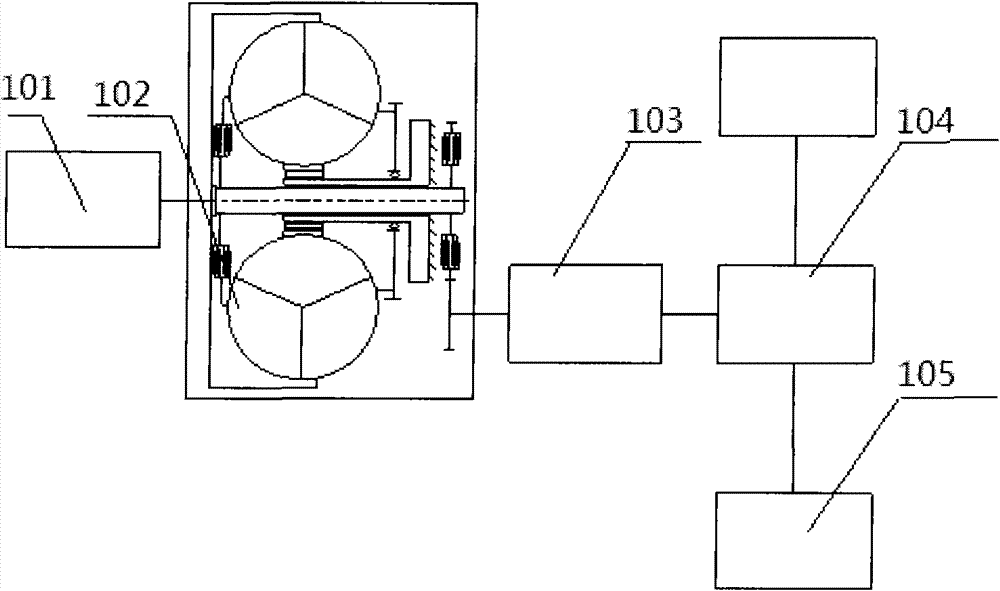

[0058] Such as figure 1 As shown, a mining vehicle hydraulic mechanical transmission system of the present invention includes an engine 101, a purely mechanical gearbox 103, a final reducer 104, and a wheel speed reducer 105, and is characterized in that it also includes a hydraulic transmission system 102 , the engine 101 generates power and enters the hydraulic transmission system 102 to realize the functions of power buffering, switching and speed-up; the power is transmitted to the pure mechanical gearbox 103 to realize the functions of shifting and deceleration and increasing torque; the power is transmitted again The final drive 104 and the wheel reducer 105 are finally transmitted to the tires to drive the vehicle forward.

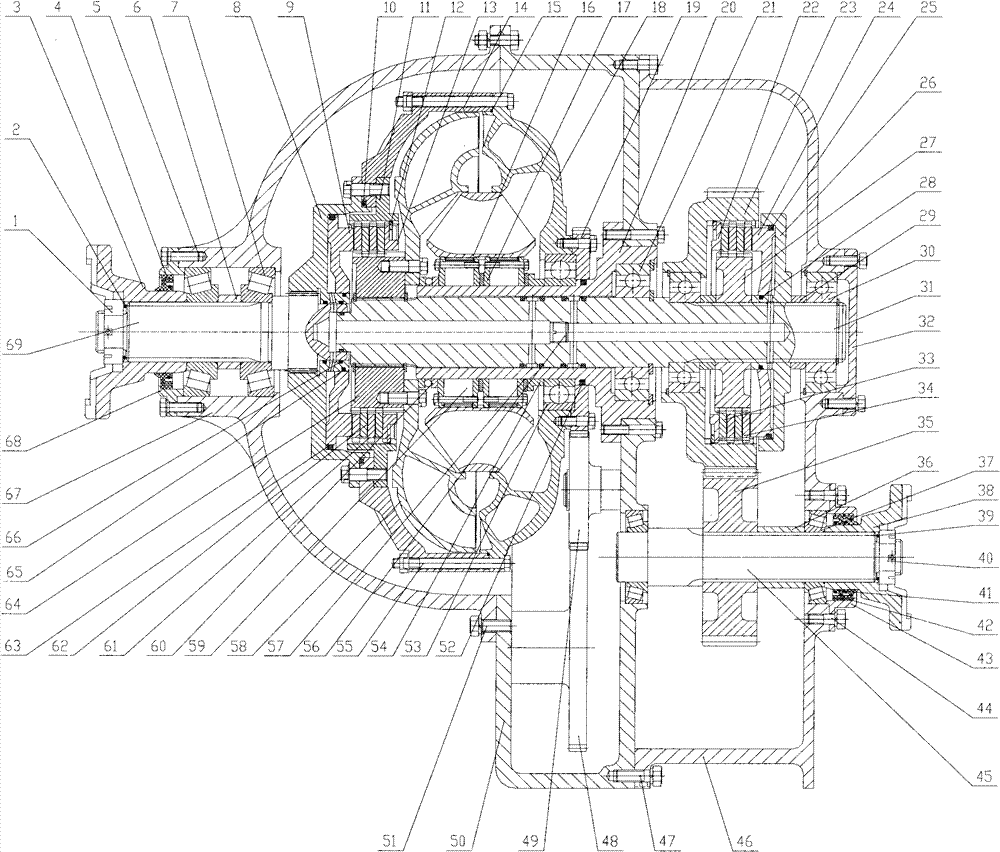

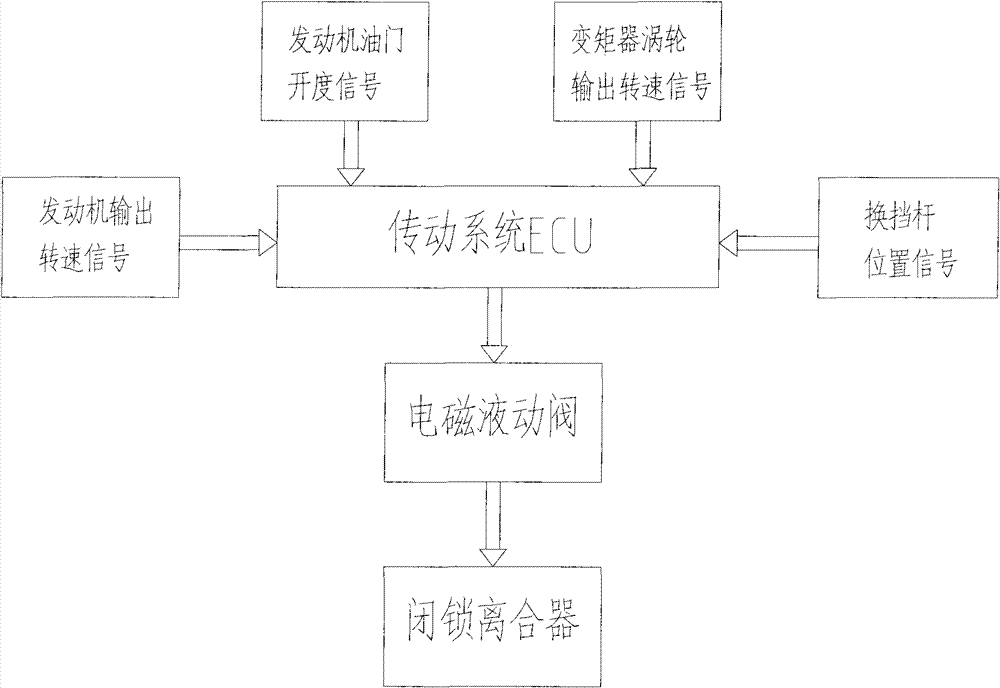

[0059] The hydraulic transmission system of the present invention includes: a power input part, a torque converter with a lock-up clutch, a speed increasing device, a shift clutch, two pump power output ports and a power output part. The specific s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com