Assembly of carbon tank and secondary air filter

A technology of air filter and carbon canister, which is applied in the direction of charging system, transportation and packaging, machine/engine, etc. It can solve the problems of occupying the layout space of the fuel tank, many installation points, and inconvenient layout, etc., and achieves a compact and smooth pipeline layout. The effect of reducing the assembly time and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

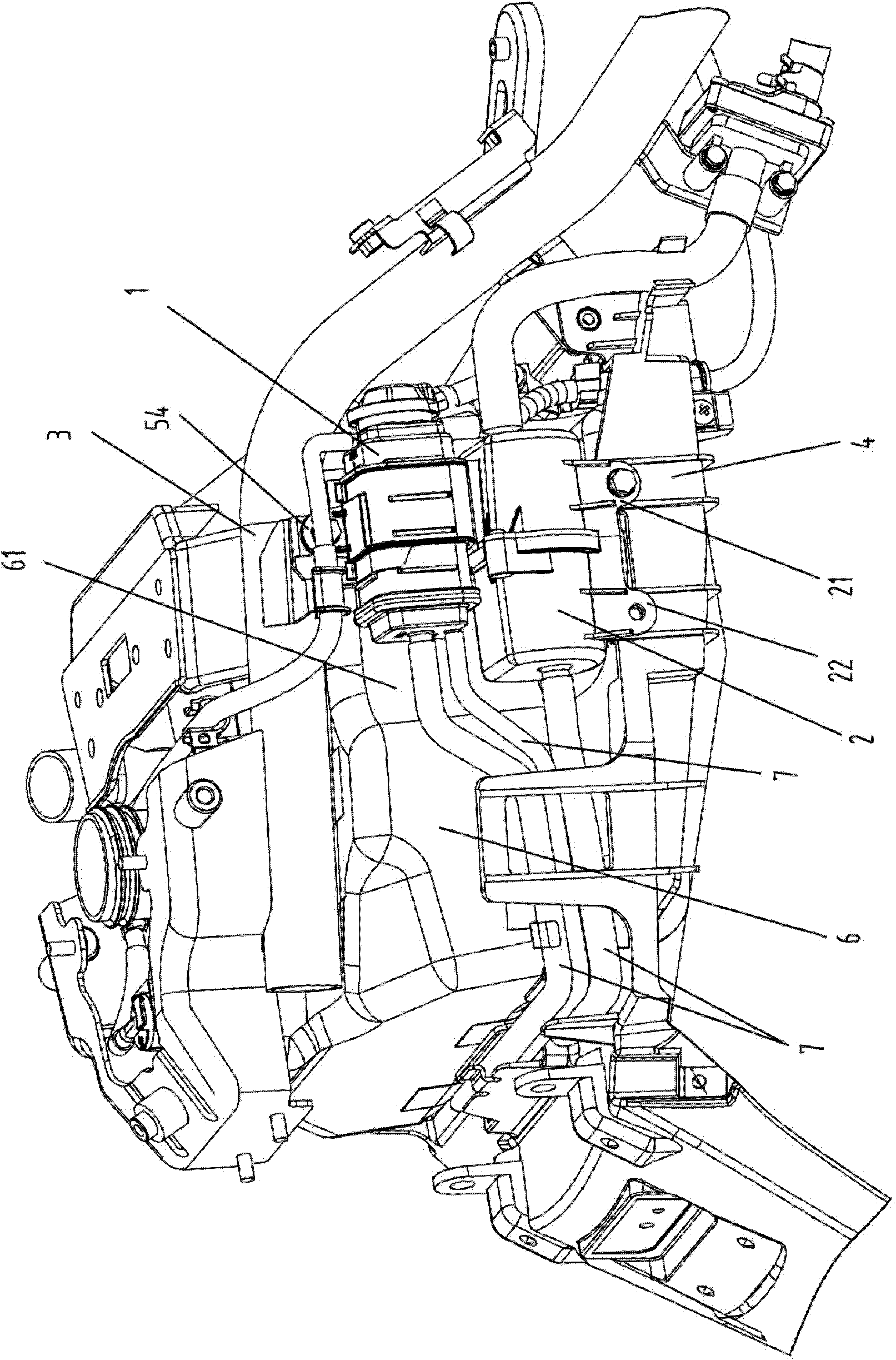

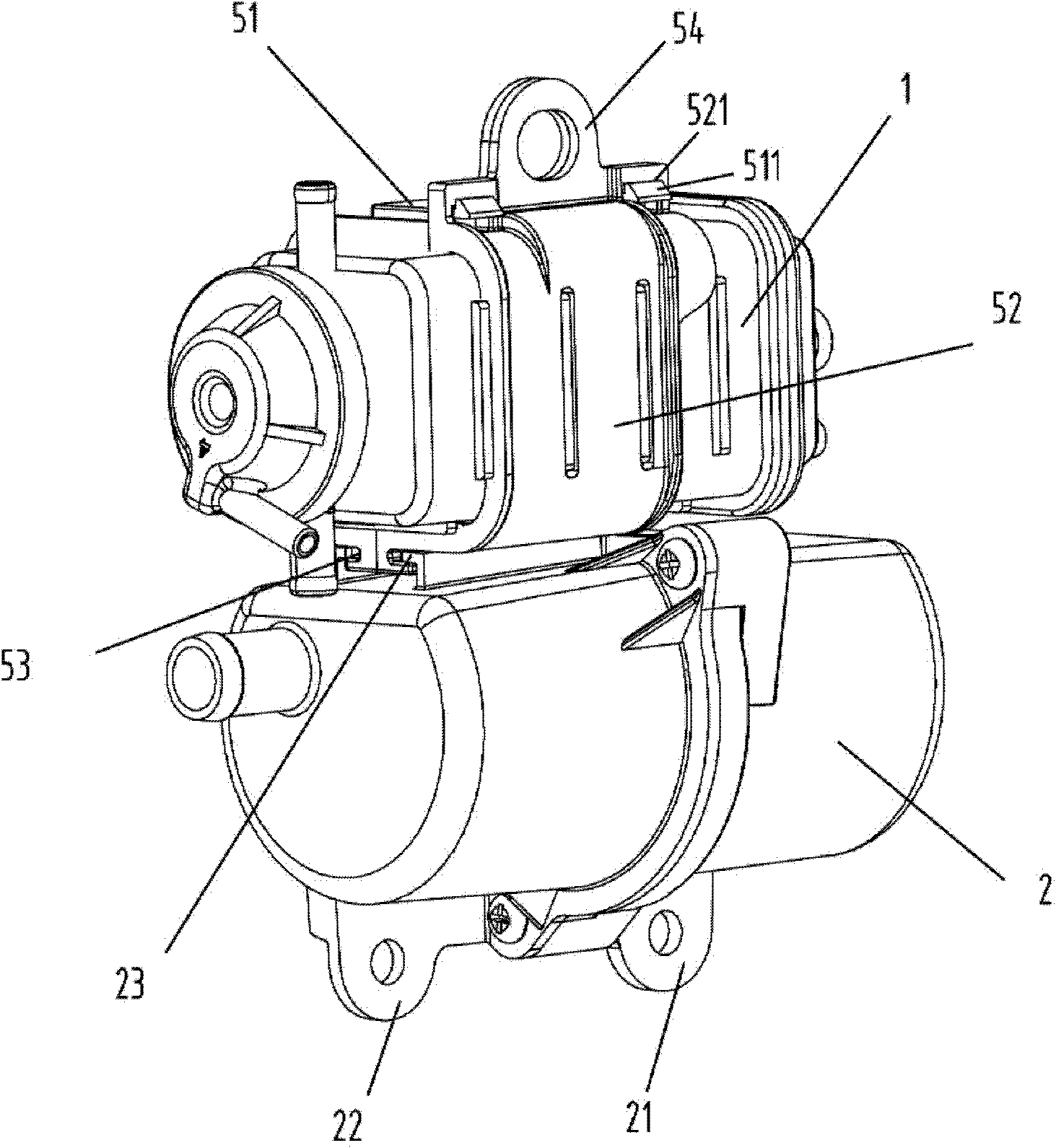

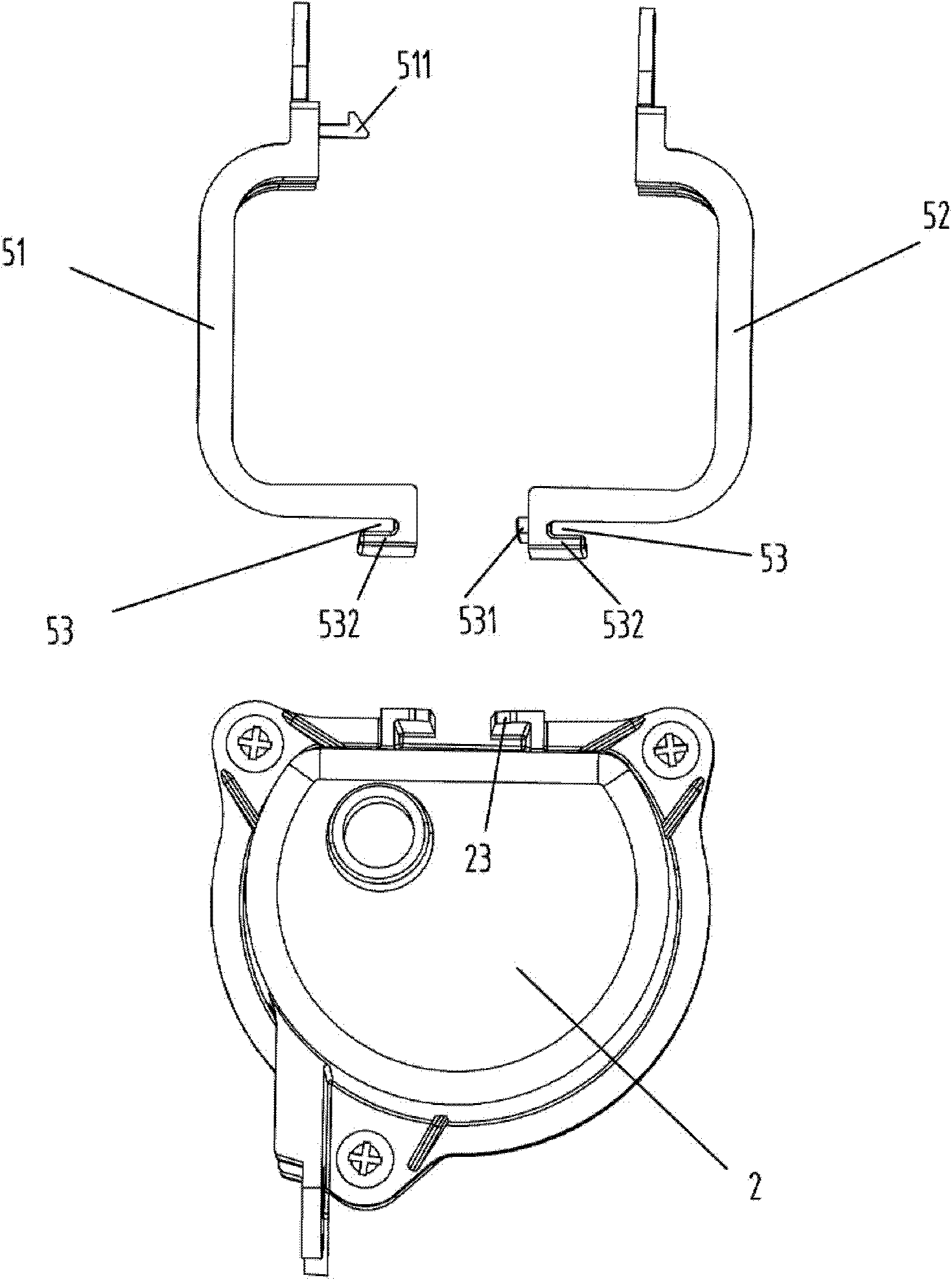

[0014] refer to figure 1 , figure 2 , an assembly assembly of a carbon canister and a secondary air filter, which includes a carbon canister 1 and a secondary air filter 2, the carbon canister 1 is fixedly installed on the secondary air filter 2 to form an integrated assembly, and its connection The method can be bolt connection, buckle connection or plug-in structure, etc. The buckle connection form is: the lower end of the shell of the carbon canister 1 and the upper end of the shell of the secondary air filter 2 are fastened and connected through hooks and holes.

[0015] The assembly assembly is fixedly mounted on the vehicle frame 3 and / or the rear fender 4, and the assembly assembly is arranged on the right side of the rear fuel tank 6 of the motorcycle (viewed from the driver's direction). The preferred design is: The assembly assembly is at least partly located in the recess 61 in the middle front part of the right side of the fuel tank 6, and is covered in the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com