A pharmaceutical production system

A pharmaceutical production and platform technology, applied to the types of packaging items, caps, liquid handling, etc., can solve problems such as low production efficiency, low degree of automation, and impact on the environment of clean areas, and achieve compact and smooth layout, improve production efficiency, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

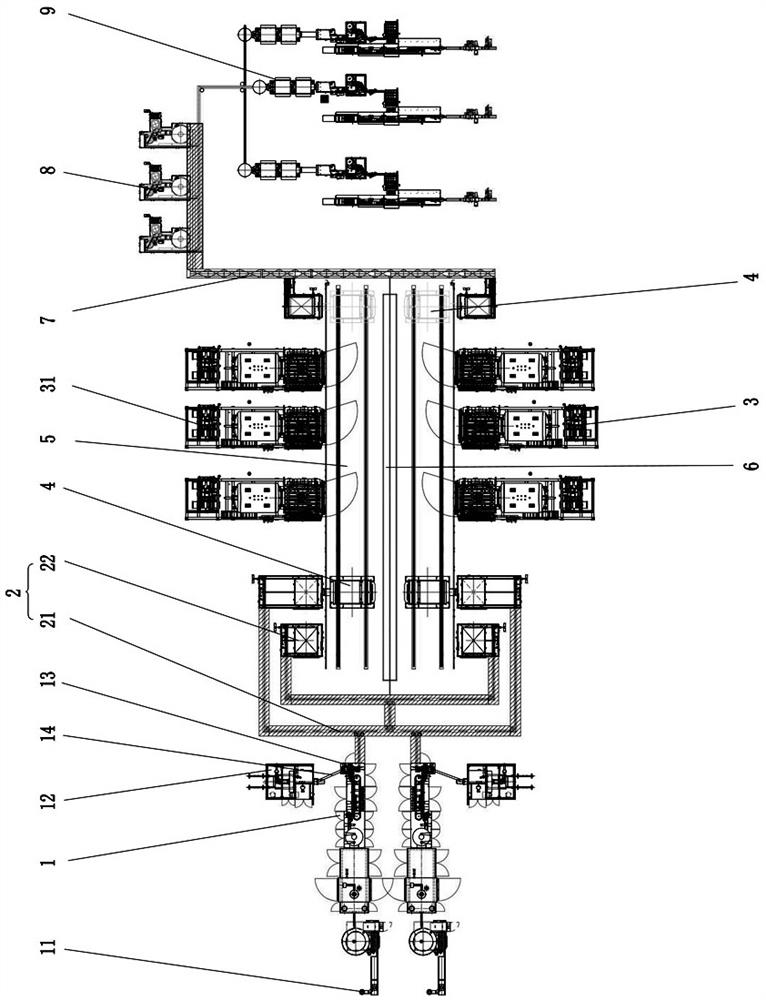

[0019] figure 1 An embodiment of the pharmaceutical production system of the present invention is shown. The pharmaceutical production system includes a loading platform 2, more than two washing, drying, filling and sealing linkage lines 1 and two rows of freeze-drying units 3. The loading platform 2 is connected to all washing At the bottle outlet end of the drying, filling and sealing linkage line 1, each row of freeze-drying units 3 is docked with the loading platform 2 through a mobile conveying trolley 4, and the conveying tracks 5 of the two mobile conveying trolleys 4 are set parallel to each other and connected with the washing, drying and filling The bottle conveying direction of the sealing linkage line 1 is parallel, and the freeze dryers 31 of each row of freeze-drying units 3 are all provided with one side of the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com