Detachable skid pressurizing integration system

An integrated system, skid-mounted technology, used in pipeline systems, production fluids, wellbore/well components, etc., can solve problems such as scrap, production loss, and inability to implement effective maintenance, and achieve the effect of shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

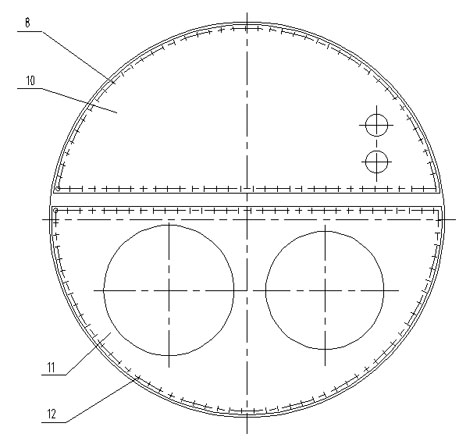

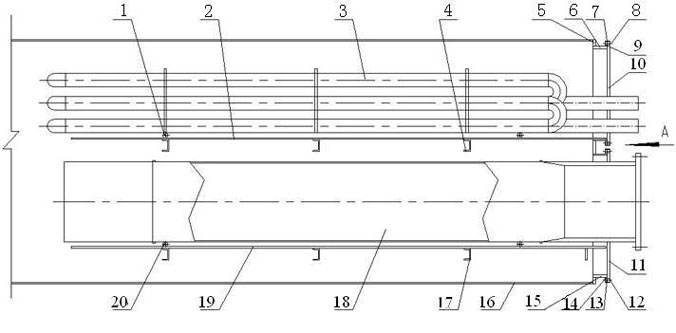

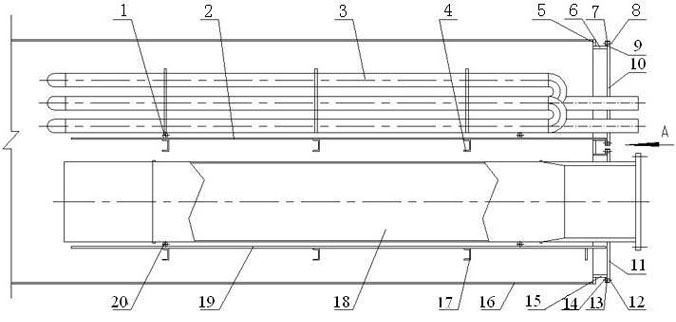

[0011] Such as figure 2 As shown, the skid-mounted pressurization integrated system with disassembly capability includes: heating furnace barrel 16, heating coil 3, fire tube system 18, upper flange 9 and lower flange 14, upper flange 9 and lower flange 14 They are group-welded with the coil lead pipe 6 and the fire cylinder lead pipe 15 respectively, and the upper flange 9 is led out by lengthening the head 5 of the heating section. The upper side of the heating furnace barrel 16 is the heating coil 3, and the fire tube system 18 is fixed under the heating coil 3. The heating coil 3 is fixed on the heating coil rolling device 1. The heating coil rolling device 1 has at least two groups, the heating coil The rolling device 1 is connected to the heating coil guide rail 2, and the heating coil guide rail 2 is fixed in the upper cylinder of the heating furnace barrel 16 through the upper rail support 4. Two or more heating coil rolling devices 1 are used to make the heating coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com