Pollution treatment device for industrial dust removal

A processing device and industrial technology, applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of affecting the effect of bag dust removal, reducing the effect of dust removal, and damage to human health, so as to maintain the effect of dust removal and improve the health of the human body. Effects of processing efficiency and reduction of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

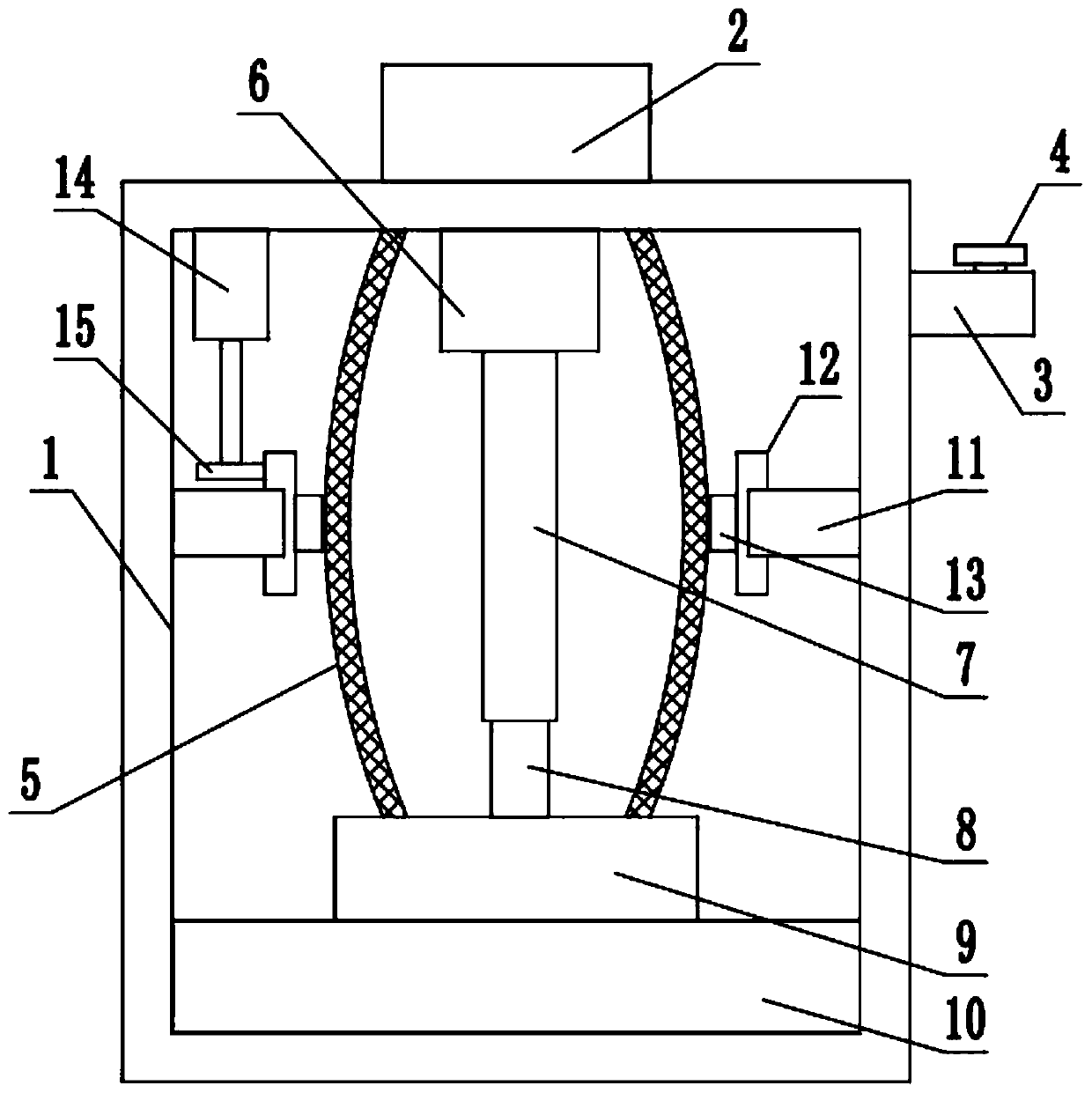

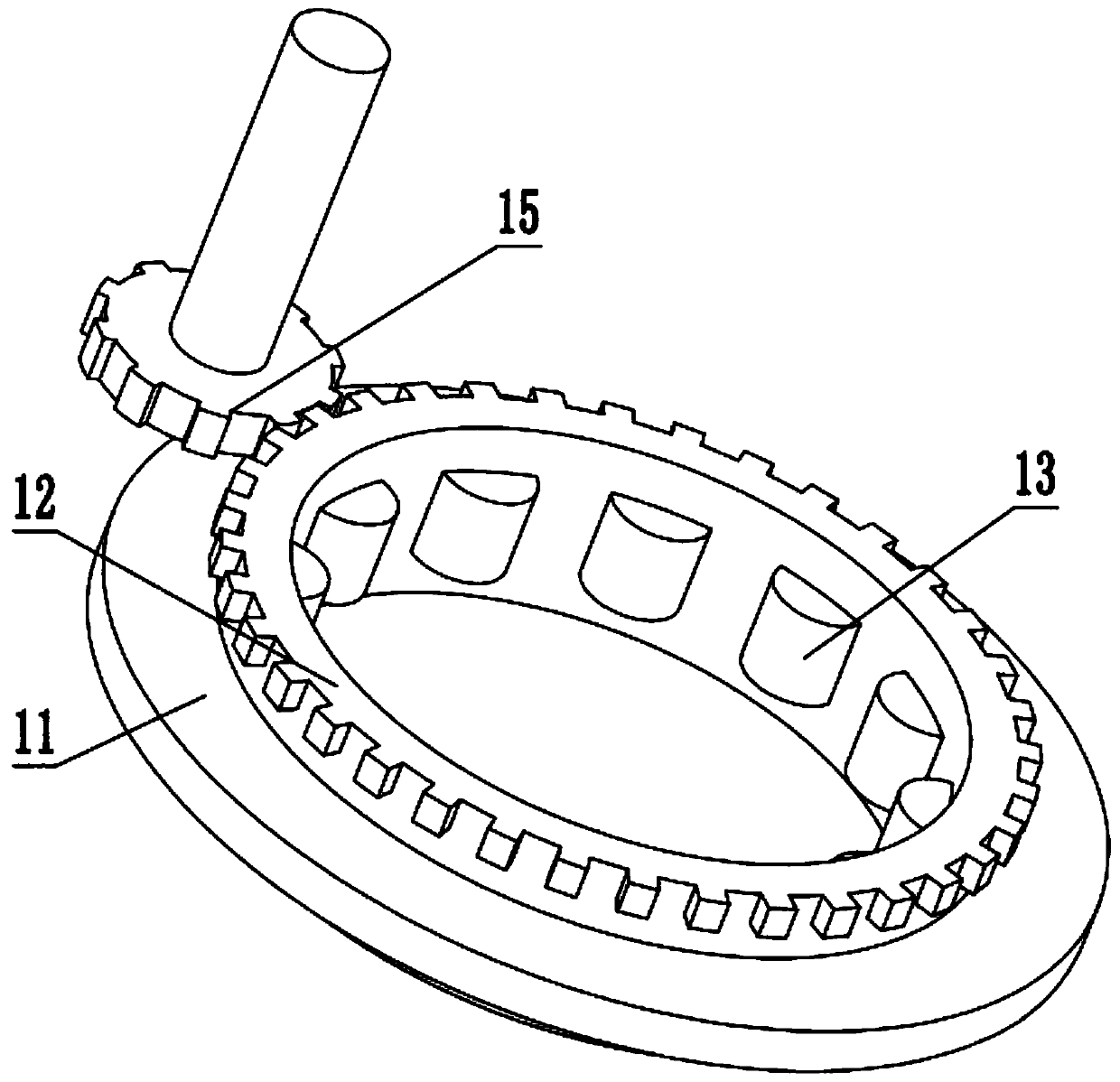

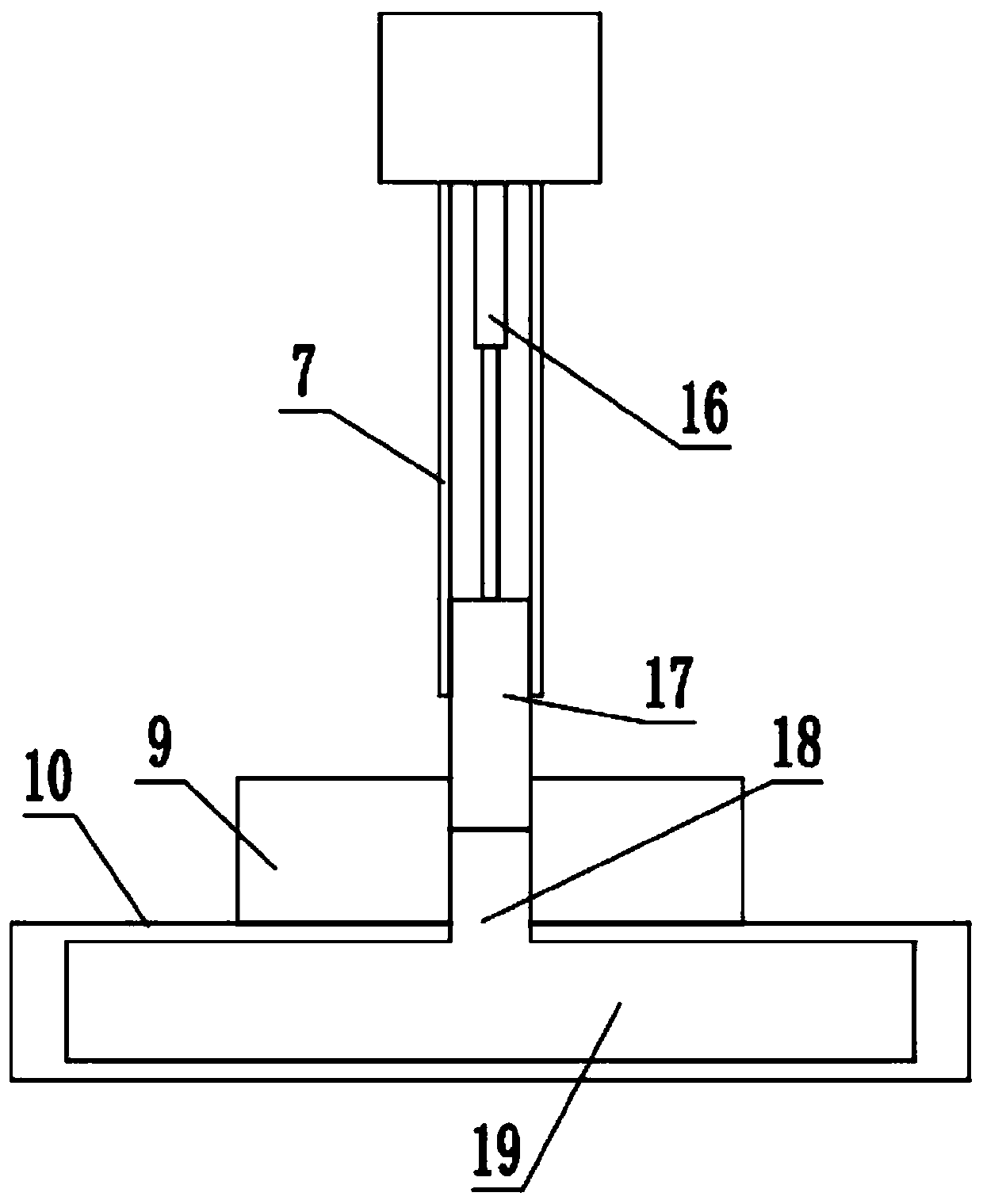

[0019] see Figure 1-3 , a pollution treatment device for industrial dust removal, comprising a dust removal box 1, an air inlet 2 is provided in the center of the top of the dust removal box 1, and an air outlet 3 is provided on the upper side of the dust removal box 1, and the air inlet 2 is used to connect the exhaust gas to transport device and introduce the dust-containing exhaust gas into the dust removal box 1 for processing, and the air outlet 3 is used to discharge the gas after dust removal; the lower part of the dust removal box 1 is provided with a bag seat 9, and a dust removal bag 5 is provided on the top surface of the bag seat 9, so The top of the dust-removing bag 5 is connected to the inner top of the dust-removing box 1, and the top of the dust-removing bag 5 is connected to the air inlet 2. When the dust-containing waste gas is processed, the waste gas directly enters the inside of the dust-removing bag 5 through the air inlet 2. In the process of continuou...

Embodiment 2

[0023] On the basis of Embodiment 1, the gas outlet 3 is provided with an on-off control valve 4 for adjusting the gas flow rate of the gas outlet 3, and when the amount of gas input into the gas inlet 2 is small, the recoil of the gas flow at the gas outlet 3 is avoided , affecting the dust removal effect.

Embodiment 3

[0025] On the basis of Embodiment 1, the dust box 10 is slidably connected with the dust box 1, and the bottom of the dust box 1 has an opening of the same size as the side of the dust box 10, which is convenient for taking out the dust box 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com