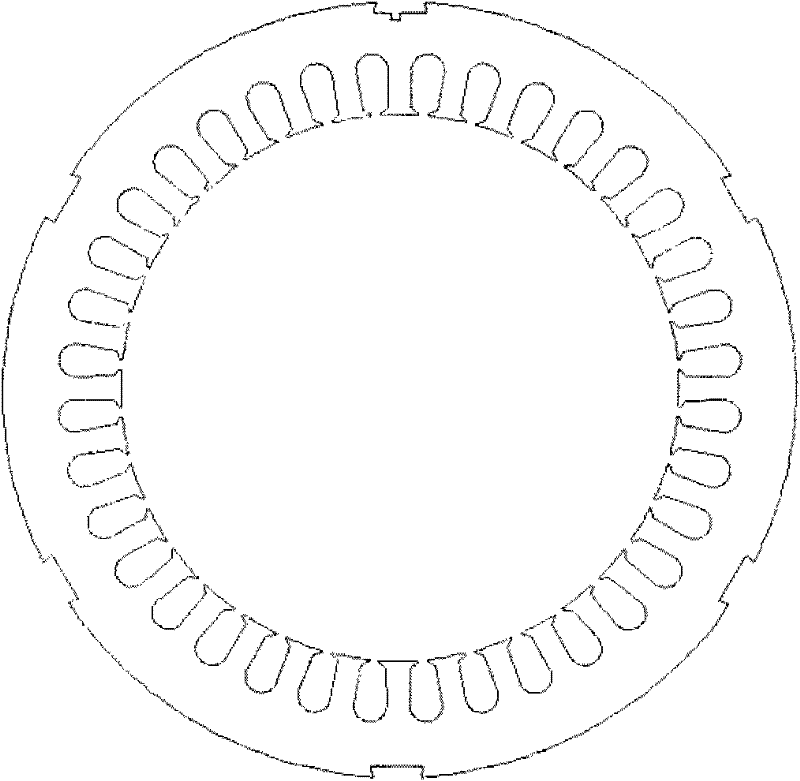

Low-loss stator punching sheet of AC motor

A technology for punching AC motors and stators, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the problems of large losses, increase production costs, reduce no-load current, and achieve obvious energy-saving effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

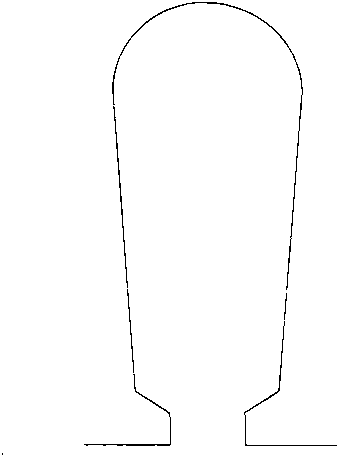

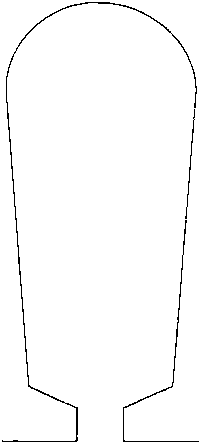

Method used

Image

Examples

Embodiment 1

[0022] Taking the Y132S-4, 5.5kW motor as an example, its notch width is 3.5mm. After adopting this patent, the notch width is reduced from the original 3.5mm to 2.7mm. Through analysis, after the 5.5kW motor with a slot width of 3.5mm is changed to 2.7mm, it is not necessary to use a thinner wire. After modification, due to the smaller slot width, the air gap coefficient and equivalent air gap are correspondingly smaller, so that the power factor is increased by about one percentage point, the full load current is reduced accordingly, and the copper consumption of the stator is reduced by about 10W, and the harmonic field on the rotor surface is weakened. The additional iron loss on the surface of the rotor is reduced from the original 24W to about 15W. Overall, the total loss of the motor is reduced by about 20W, as shown in Table 1, Table 2 and Table 3 (in Tables 1-3, no-load iron loss and The full-load copper consumption is reduced by 18W, further considering that the redu...

Embodiment 2

[0032] Choose YX3-90S-6, 0.75kW motor, the stator notch width of the traditional groove type is 2.8mm, in the present invention, the notch width is reduced to 60% of the original, that is, changed from 2.8mm to 1.7mm. The motor was originally designed with a wire gauge of 0.75mm. After the improvement, in order to ensure that the cross-sectional area of the wire remains unchanged, it is changed to two 0.53mm wires and wound together. The loss comparison between the two is shown in Table 4 and Table 5. After the improvement, the no-load loss can be reduced by 16. %, from 74W to 62W, the energy saving effect is remarkable. In this example, the notch width can also be reduced to 50% of the original, that is, from 2.8mm to 1.4mm. When inserting the wire, either the original 0.75mm single wire or two 0.53mm parallel wires can be used. The no-load loss data in this case is shown in Table 6, the loss value is reduced from 74W to 52W, and the energy saving effect is more significant...

Embodiment 3

[0041] Y225S-4, 37kW motor, the original notch width is 4mm, the improved notch width is 3.4mm (85% of the original), the original design wire gauge is 1.25mm, after the improvement is still not improved, it takes man-hours to manufacture the motor and Difficulty doesn't matter much, in this case the no-load loss is reduced by about 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com