Process for laminating the iron core of distribution transformer

A technology of distribution transformer and new technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc. It can solve the problems of low utilization rate of silicon steel sheet materials, low efficiency of iron core rolling, and inconvenient coil winding, etc., to achieve Improve short-circuit impact resistance, small no-load current, and small magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

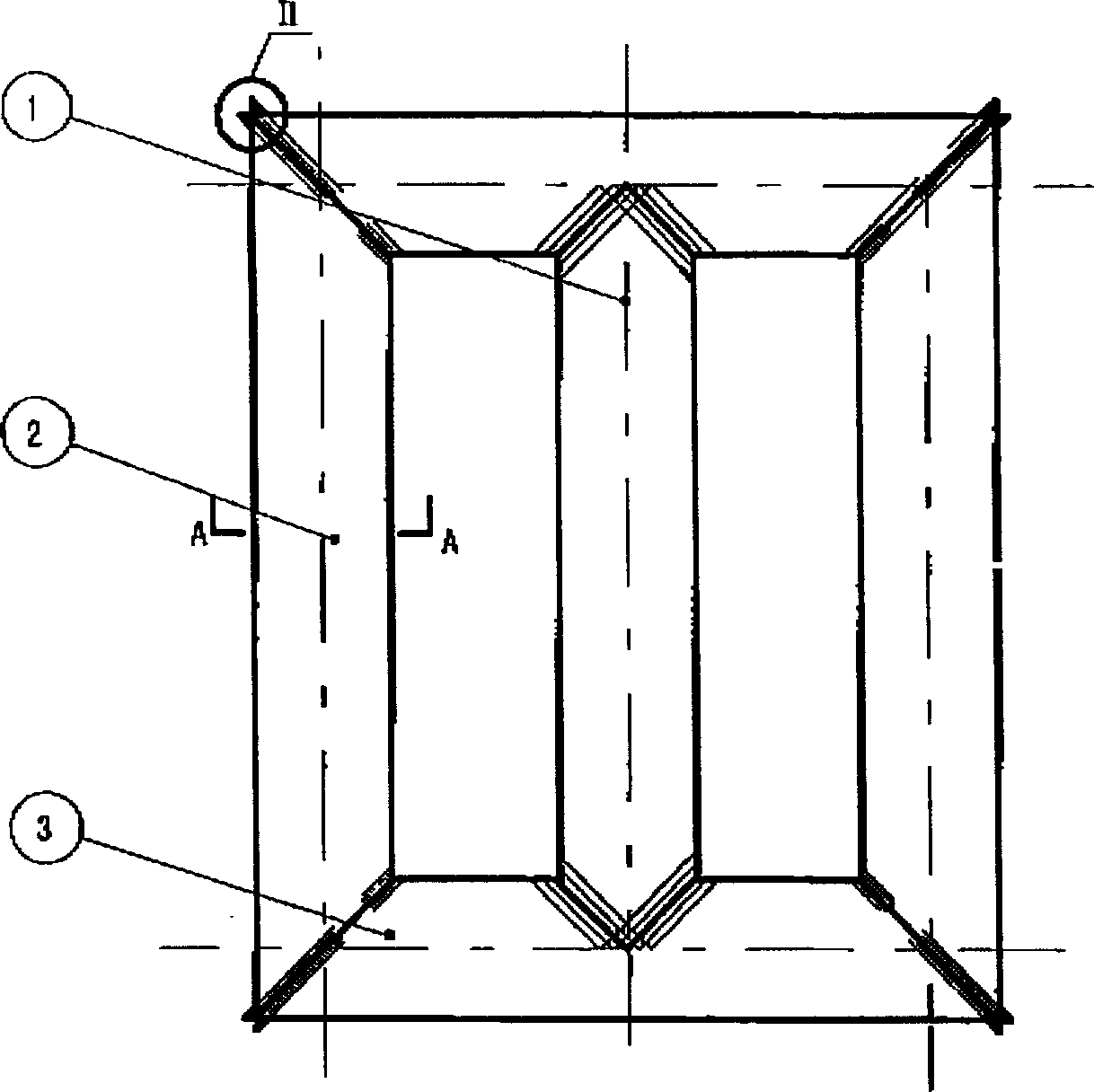

[0009] Referring to the accompanying drawings for the embodiments, the structure of the distribution transformer manufactured by this process is described in detail below: a circular cross-section stacked iron core transformer, which is composed of an iron core placed in an oil tank in the transformer housing, high and low voltage coil windings, and the iron core It consists of intermediate sheet 1, edge sheet 2 and iron yoke 3. 45-degree full oblique joints are adopted between the intermediate sheet 1, the edge sheet 2 and the iron yoke 3, and the single-sheet stacked and double-sheet mixed stacked structures are adopted.

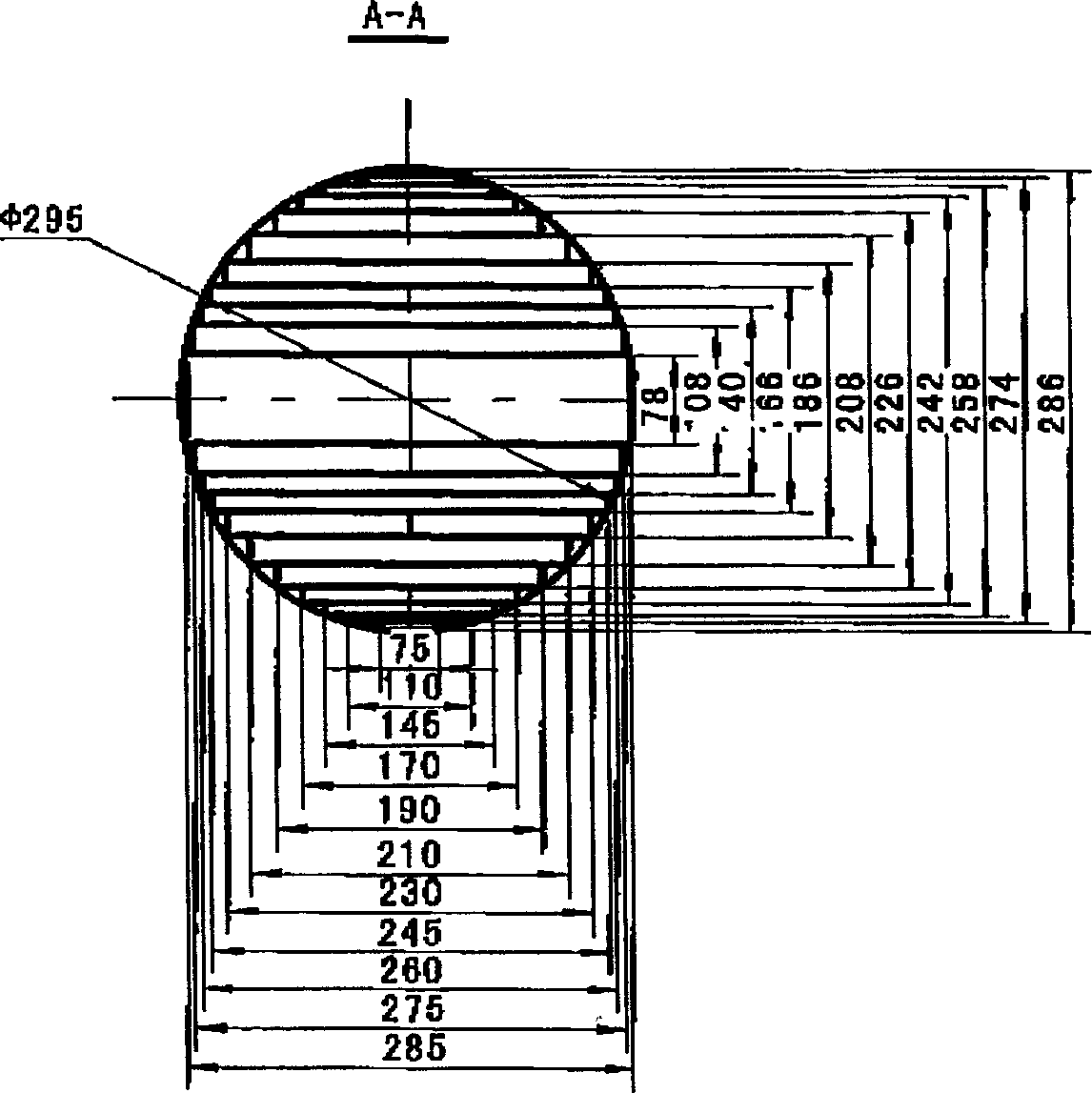

[0010] For the specific dimensions of the stacked iron core with circular cross-section, please refer to the attached figure 2 , the cross-sectional area is 635.447 square millimeters, and the effective lamination coefficient is 0.97.

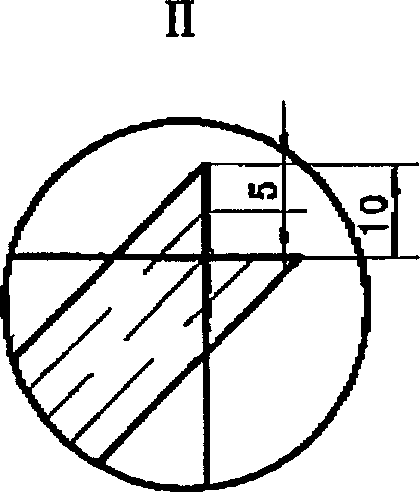

[0011] The 45-degree fully oblique joint in the present invention means that the silicon steel sheets on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com