Internal bias hub motor

A technology of offset wheel and output gear, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems such as the inability of hard tooth surface transmission to overcome the noise problem, the radial and axial dimensions of the stator are too large, and the overall efficiency is low. , to achieve the effect of low cost, clear magnetic circuit and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

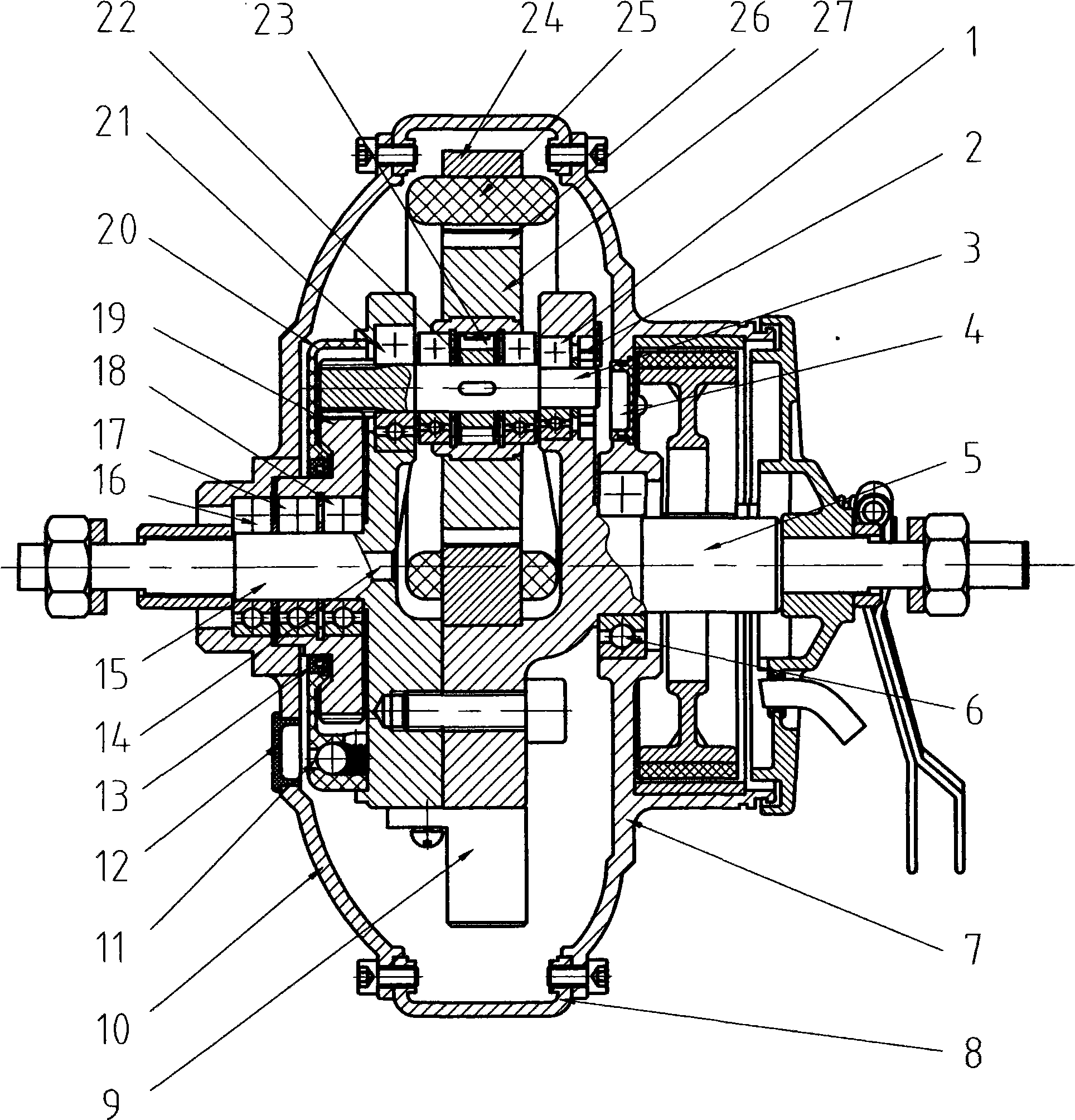

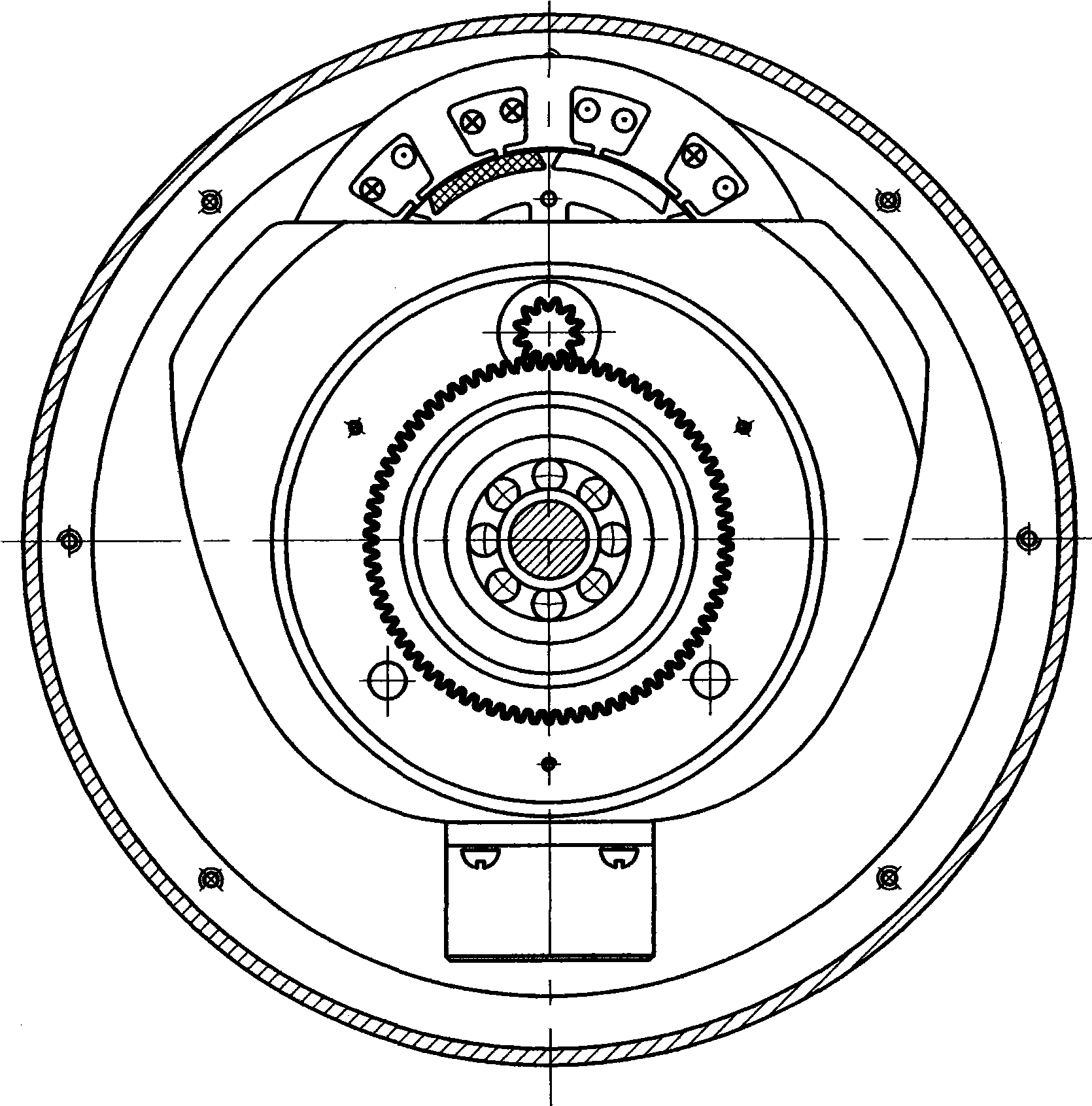

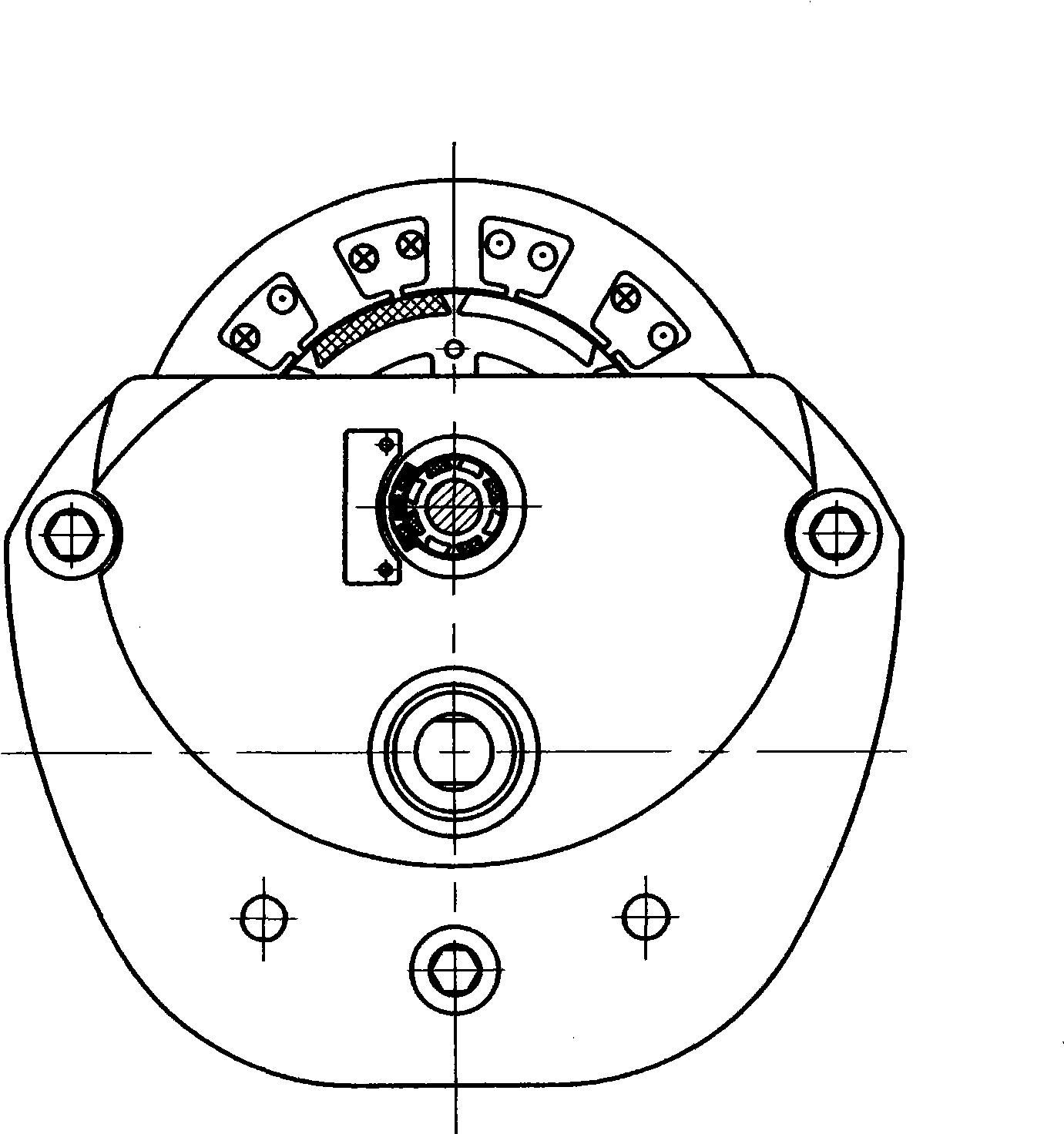

[0027] see figure 1 , 2 , 3, 4, 5, 6 and 7, inner offset wheel hub motors, the left end cover 10 is fixed on the left side of the housing 8, the right end cover 7 is fixed on the right side of the housing 8, and the left end cover 10 is sleeved on the front through the left end cover bearing 16 On the crankshaft 15, the right end cover 7 is sleeved on the rear crankshaft 5 through the right end cover bearing 6. The front crankshaft 15 and the rear crankshaft 5 are fixedly connected, and the stator 24 is fixed in space. The stator 24 is characterized by stacking of silicon steel sheets. There are round holes, and 12 winding slots are evenly distributed on the round hole wall, and the winding slots are wound with three-phase short-distance winding coils 25, and the rotor 27 is sleeved in the round holes of the stator 24, and the rotor 27 is characterized in that the outer circumference is evenly distributed 8 Two permanent magnet poles 26 and 8 wedge-shaped buckles, the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com