Electromagnetic braking device for rotary main shaft

A technology of electromagnetic braking and rotating spindle, which is applied in the direction of asynchronous induction clutch/brake, etc., can solve the problems of unusable high-speed spindle equipment, inability to run for a long time, large electromagnetic loss, etc., and achieve good heat dissipation and energy saving effects. Effect of reducing electromagnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

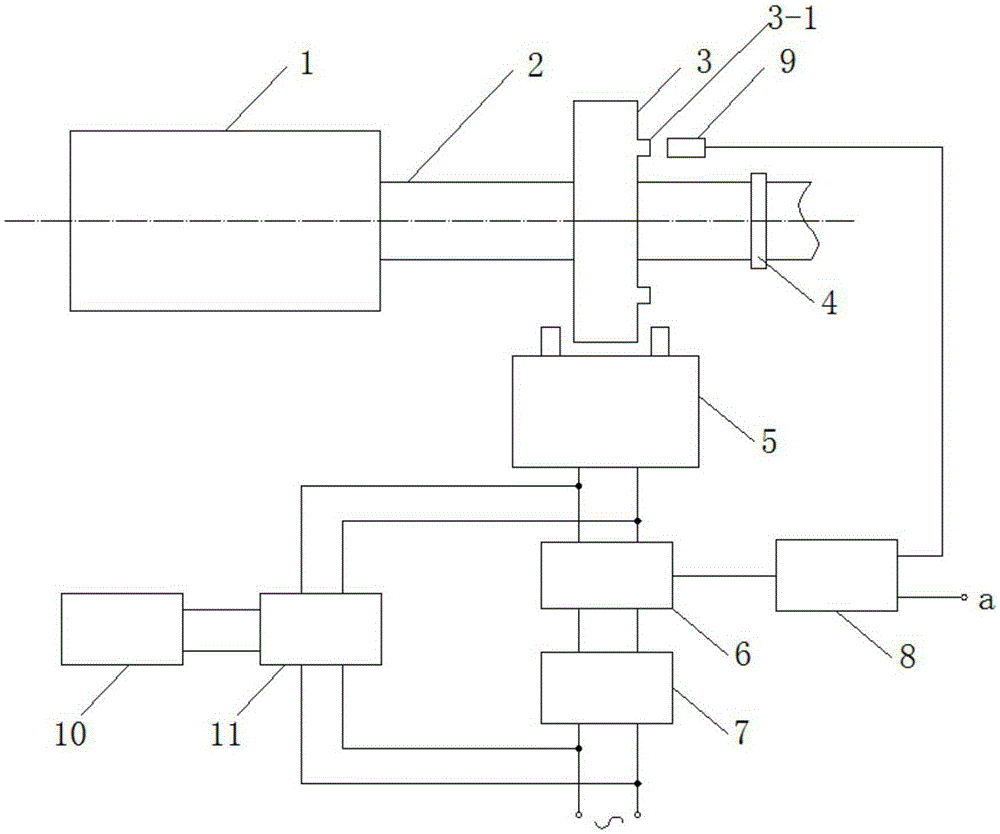

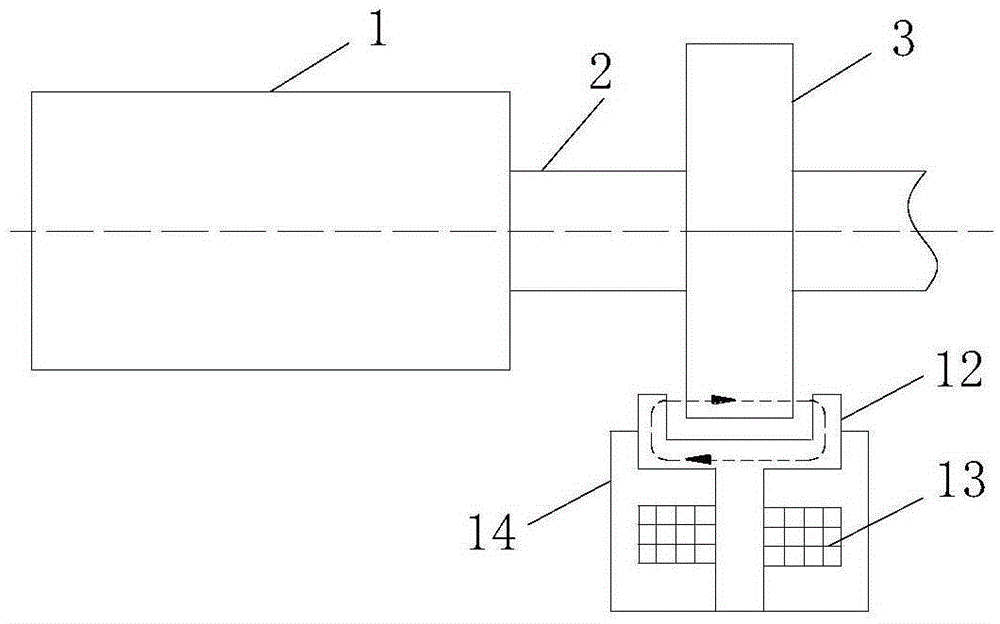

[0022] The rotating spindle electromagnetic brake device of the present invention has a structure such as figure 1 Shown, including braking part, excitation power supply and measurement and control part. The braking part includes a high-permeability electromagnetic brake disc 3 and a DC electromagnet 5 arranged on the main shaft 2. The main shaft 2 is also connected with a motor 1 and a coupling 4. The brake disc 3 is located at the two magnetic poles 12 of the DC electromagnet 5. Between them, they are not in contact with the DC electromagnet 5, and the positions of the shaft coupling 4 and the motor are respectively located on both sides of the brake disc 3. Two identical cylindrical magnet protruding blocks are arranged symmetrically on the right side of the brake disc 3 to detect the spindle speed. The size of the protruding blocks is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com