Energy-saving lighting device

A lighting device, energy-saving technology, applied in the direction of electrical components, electric solid state devices, circuits, etc., can solve problems such as unfavorable heat dissipation of LED chips, cracking of adhesive layers, and poor edge sealing, so as to facilitate heat dissipation and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

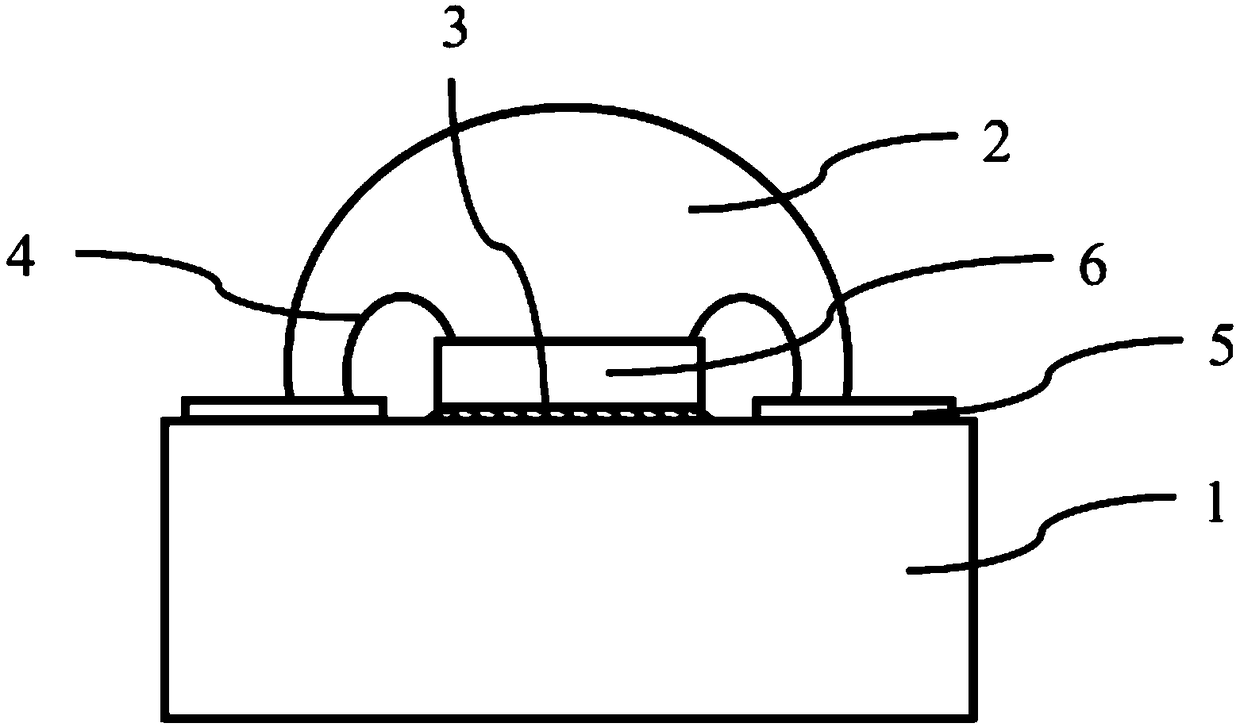

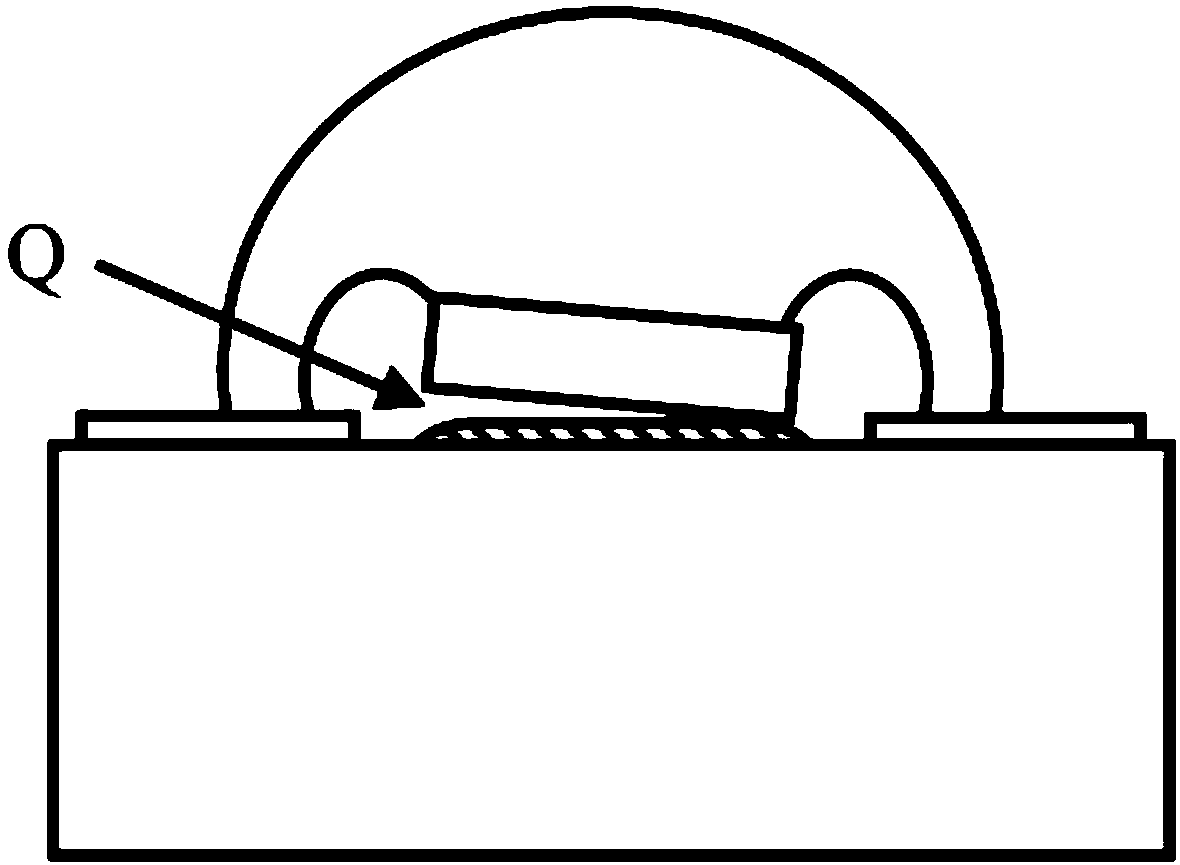

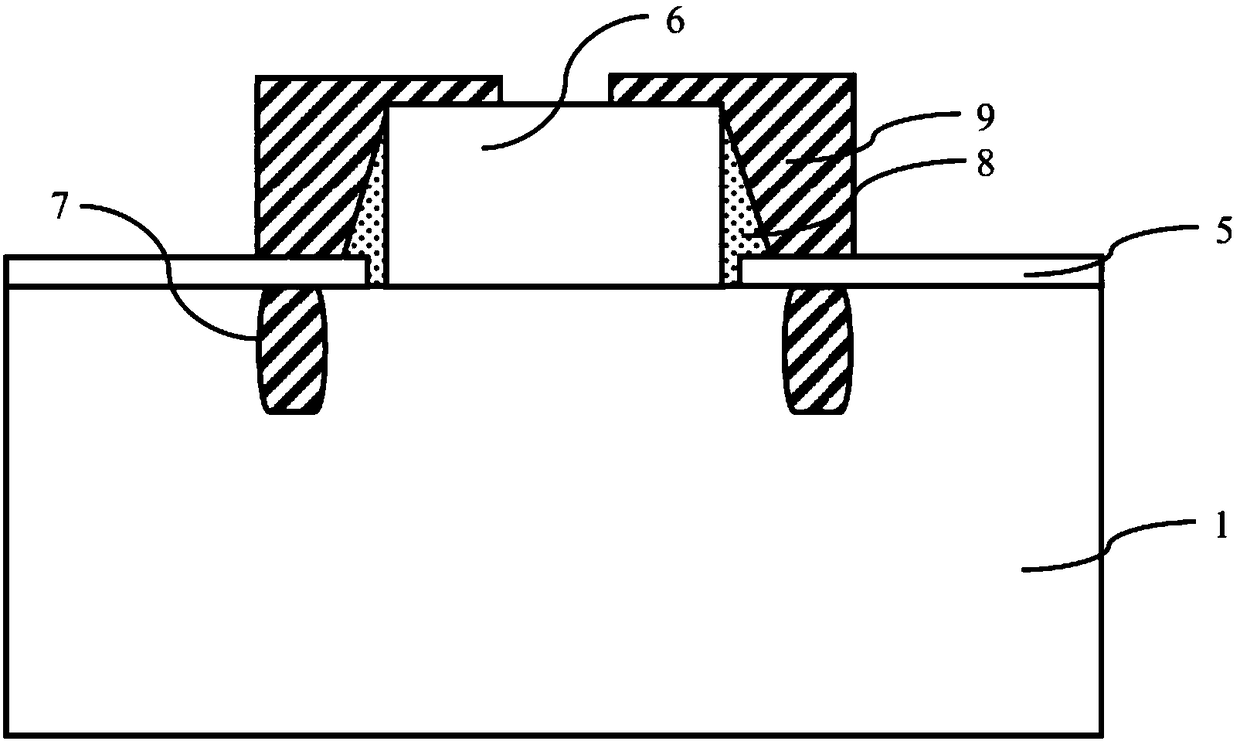

[0017] see image 3 , the energy-saving lighting device of the present invention, which includes a heat dissipation substrate 1, an LED chip 6, a conductive pattern 5, a first insulating material layer 8 and a transparent conductive layer 9; the heat dissipation substrate 1 has a first conductive pattern 5 surface and a second surface opposite to the first surface, the LED chip 6 is fixed to the portion of the first surface of the heat dissipation substrate 1 that is not provided with the conductive pattern 5 through an adhesive layer (not shown) , and there is a gap between the LED chip 6 and the conductive pattern 5, the heat dissipation substrate 1 is also provided with a protruding groove 7 located on the first surface, and the conductive pattern 5 is provided with the Extend into the through hole (not shown) corresponding to the groove; the first insulating material layer 8 covers the side of the LED chip 6 and fills the gap; the transparent conductive layer 9 is electric...

no. 2 example

[0019] see Figure 4 , the present invention also provides another energy-saving lighting device, which includes a heat dissipation substrate 1, an LED chip, a conductive pattern 5, a second insulating material layer 11 and a bonding wire; the heat dissipation substrate 1 has a first conductive pattern 5 One surface and a second surface opposite to the first surface, the LED chip is fixed to the part of the first surface of the heat dissipation substrate 1 that is not provided with the conductive pattern 5 through an adhesive layer (not shown) , and there is a gap between the LED chip 6 and the conductive pattern 5, the heat dissipation substrate 1 is also provided with a protruding groove 10 on the first surface, and the protruding groove 10 is arranged in the gap The LED chip includes a light-emitting middle area 61 and a redundant area 62 surrounding the light-emitting area 61. The side of the redundant area 62 is provided with an annular groove 12, and the annular groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com