LED epitaxial wafer grown on magnesium aluminate scandium substrate and preparation method thereof

A LED epitaxial wafer, magnesium scandium aluminate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the unfavorable high-quality GaN thin-film growth and high-performance GaN thin-film device industrialization, large-size substrate preparation process difficulties, substrate Poor bottom single crystal quality and other problems, to achieve the effect of heat dissipation, improve light reflection, and improve crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

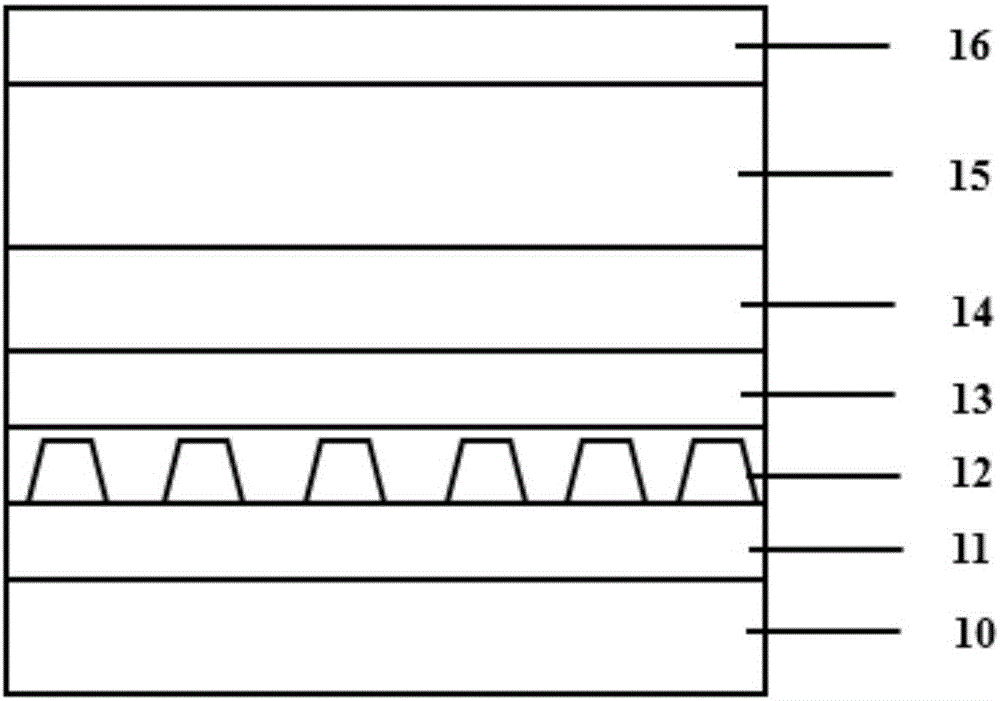

[0038] The preparation method of the LED epitaxial wafer grown on the magnesium scandium aluminate substrate of the present embodiment comprises the following steps:

[0039] (1) Selection of the substrate and its crystal orientation: Magnesium aluminate scandium substrate is used, with the (0001) plane offset from the (11-20) plane by 0.5-1° as the epitaxial plane, and the crystal epitaxial orientation relationship is: (0001) of GaN ) plane parallel to ScMgAlO 4 (0001) face;

[0040] (2) Substrate annealing treatment, the specific process of the annealing is: the magnesium scandium aluminate substrate is annealed at 600° C. for 1 hour in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

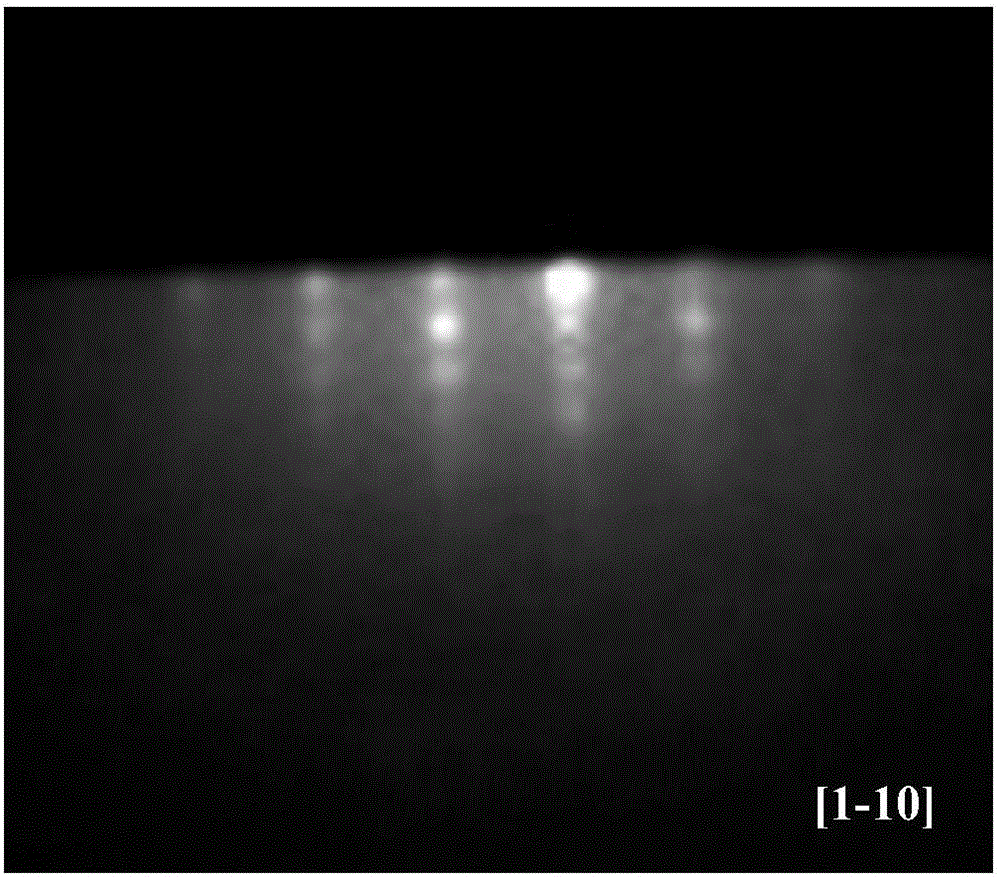

[0041] (3) GaN buffer layer epitaxial growth: the substrate temperature is adjusted to 450°C, and the pressure in the reaction chamber is 1.0×10 by pulsed laser deposition technology. -5 Pa, laser energy density is 2.0J / cm 2 A GaN buff...

Embodiment 2

[0053] The preparation method of the LED epitaxial wafer grown on the magnesium scandium aluminate substrate of the present embodiment comprises the following steps:

[0054] (1) Selection of the substrate and its crystal orientation: Magnesium aluminate scandium substrate is used, with the (0001) plane offset from the (11-20) plane by 0.5-1° as the epitaxial plane, and the crystal epitaxial orientation relationship is: (0001) of GaN ) plane parallel to ScMgAlO 4 (0001) face;

[0055] (2) Substrate annealing treatment, the specific process of the annealing is: annealing the magnesium scandium aluminate substrate at 700° C. for 2 hours in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

[0056] (3) Epitaxial growth of GaN buffer layer: the substrate temperature is adjusted to 550°C, and the pressure in the reaction chamber is 4.0×10 by pulsed laser deposition technology. -5 Pa, laser energy density is 2.5J / cm 2 A GaN bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com