Bagged liquid strain inoculation machine

A liquid strain and inoculation machine technology, which is applied in horticulture, application, botany equipment and methods, etc., can solve the problems of low inoculation efficiency, economic loss, inoculation failure, etc., and achieve high inoculation efficiency, stable operation, and inoculum volume easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

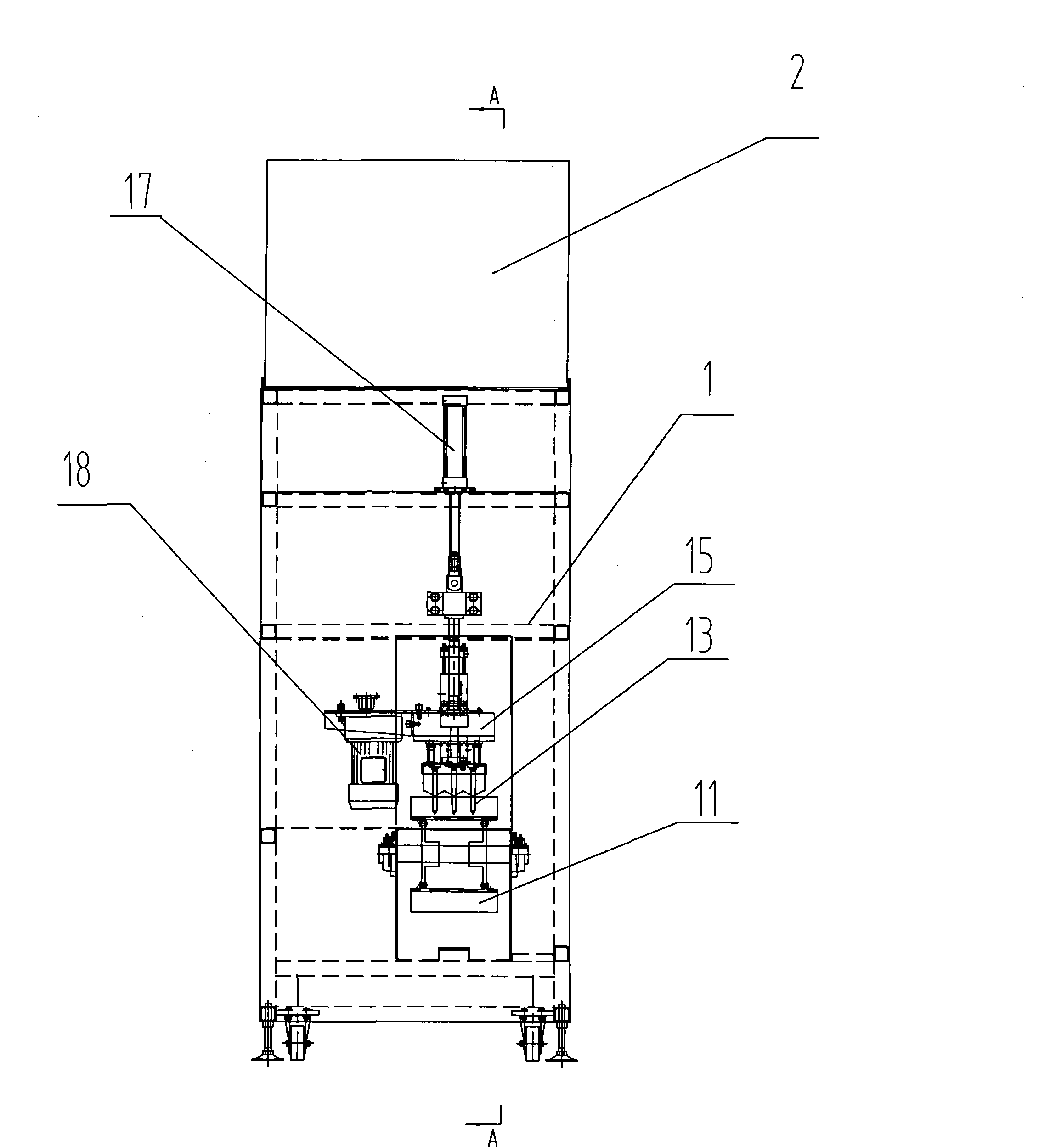

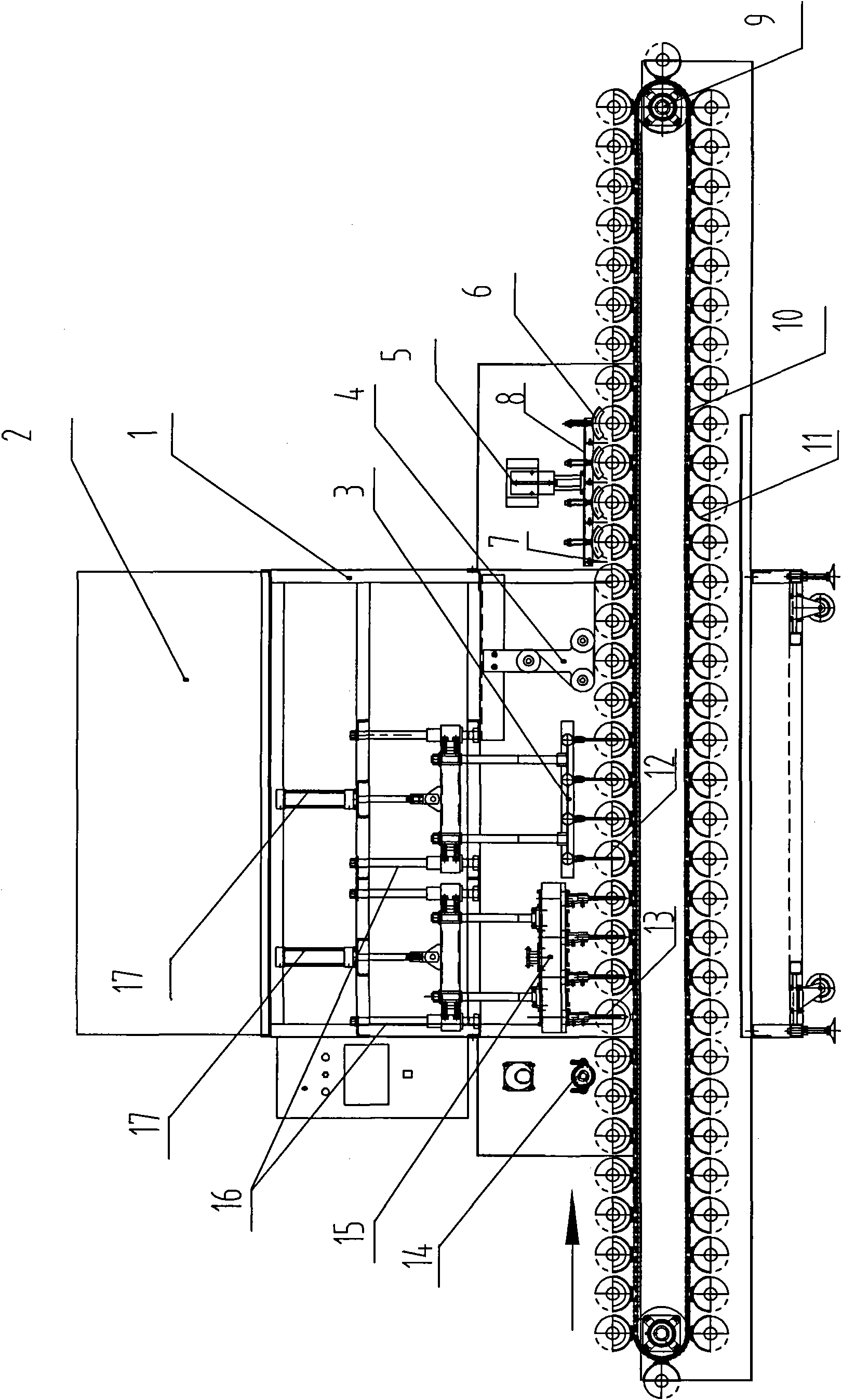

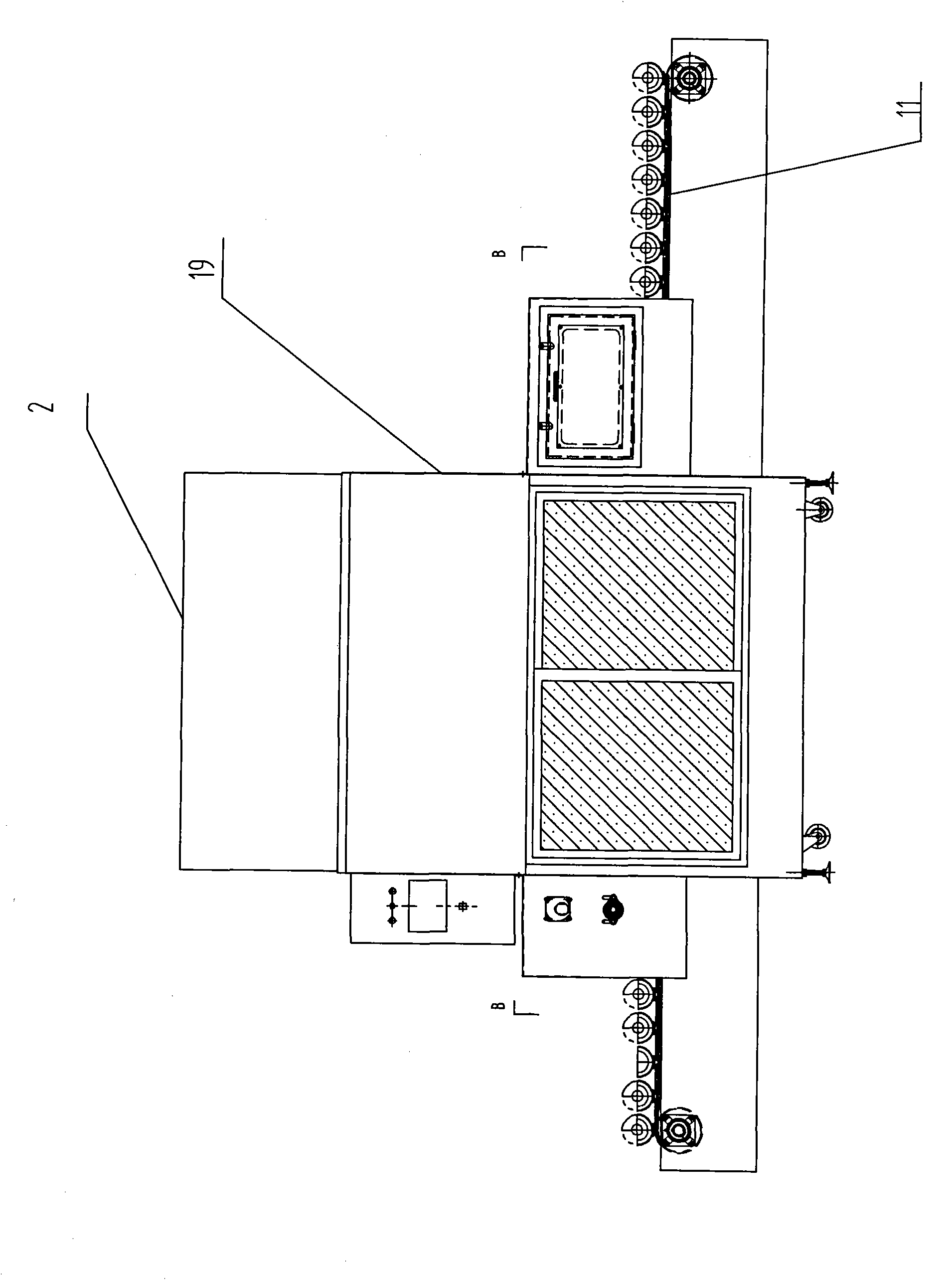

[0028] Example 1. refer to Figure 1-4. A bagged liquid strain inoculation machine, it comprises frame 1, is provided with conveying roller 9 and the conveyor belt 10 that is located on the conveyor roller 9 on frame 1; Punch hole mechanism 15, described punch hole mechanism 15 comprises support and elevating device, and elevating device is connected on the top of support, and is also connected with some puncture hole rods 13 at the bottom of support; Above conveyer belt 10, pound hole mechanism The frame 1 on the right side of 15 is also provided with an inoculation mechanism 3, and the inoculation mechanism 3 includes a frame body and a lifting device. The needle 12 is connected with the inoculation pipeline.

Embodiment 2

[0029] Example 2. In the bagged liquid strain inoculation machine described in Example 1: the punching mechanism 15 is also provided with a geared motor 18, and the geared motor 18 drives the punching rod 13 to rotate through a mechanical transmission device 21 .

Embodiment 3

[0030] Example 3. In the bagged liquid strain inoculation machine described in embodiment 1 or 2: the lower part of the punching rod 13 is cone-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com