A method of machining drum rope grooves using numerical control machine tools

A drum rope groove, using numerical control technology, applied in the direction of metal processing equipment, cutting machine, manufacturing tools, etc., can solve the problems of increased manufacturing cost, high risk, high scrap rate, etc., to improve processing efficiency, reduce labor intensity, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention discloses a method for processing a drum rope groove by using a numerical control machine tool, which comprises the following steps:

[0028] Step 1, set the direction perpendicular to the horizontal surface of the workpiece section as the X direction, and the direction parallel to the horizontal surface of the workpiece section as the Z direction;

[0029] Step 2, after clamping the workpiece blank, first rough turn the outer wall with an outer turning tool; ensure that the tolerance of the outer diameter of the reel within the full length range is within 0.5 mm.

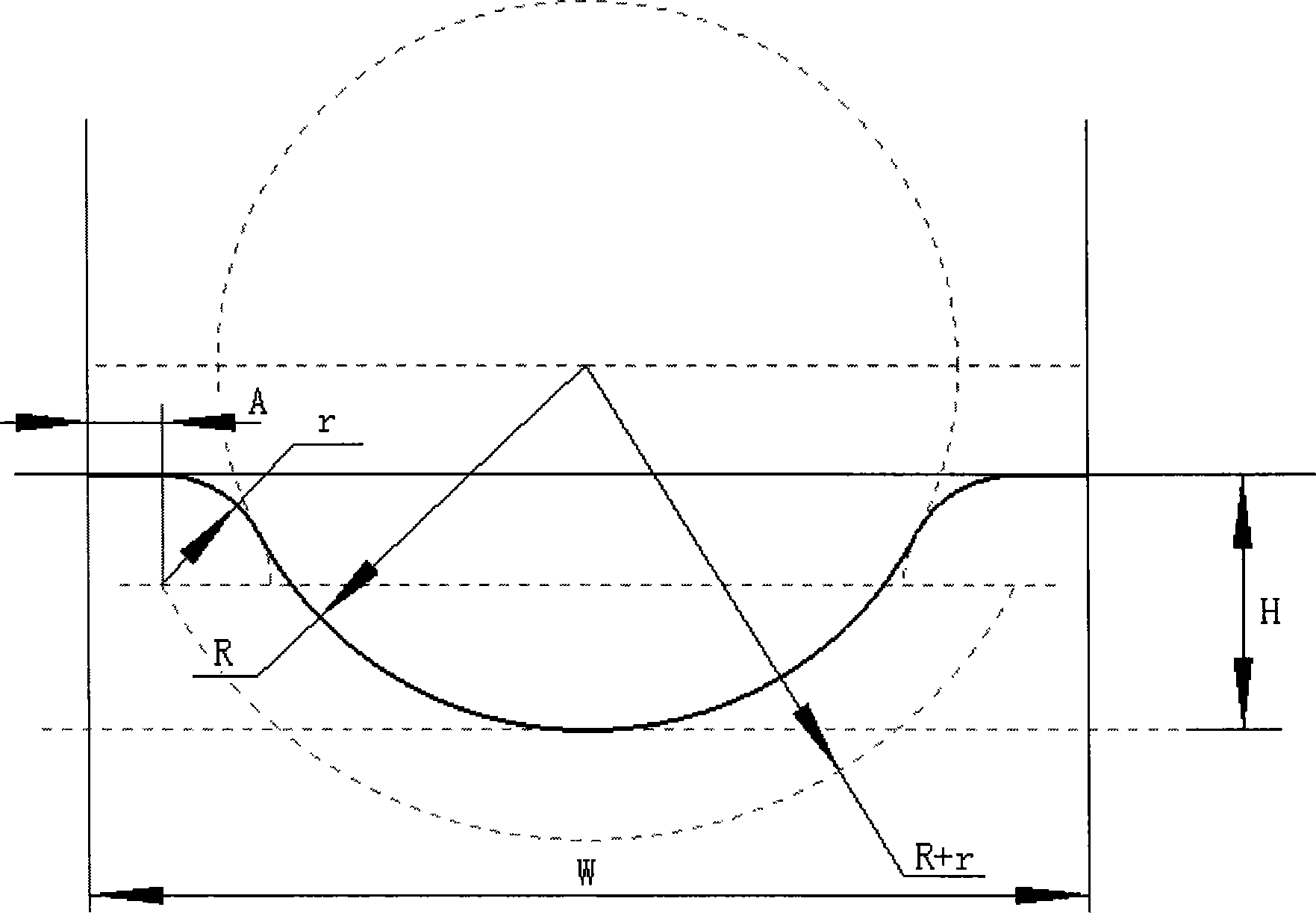

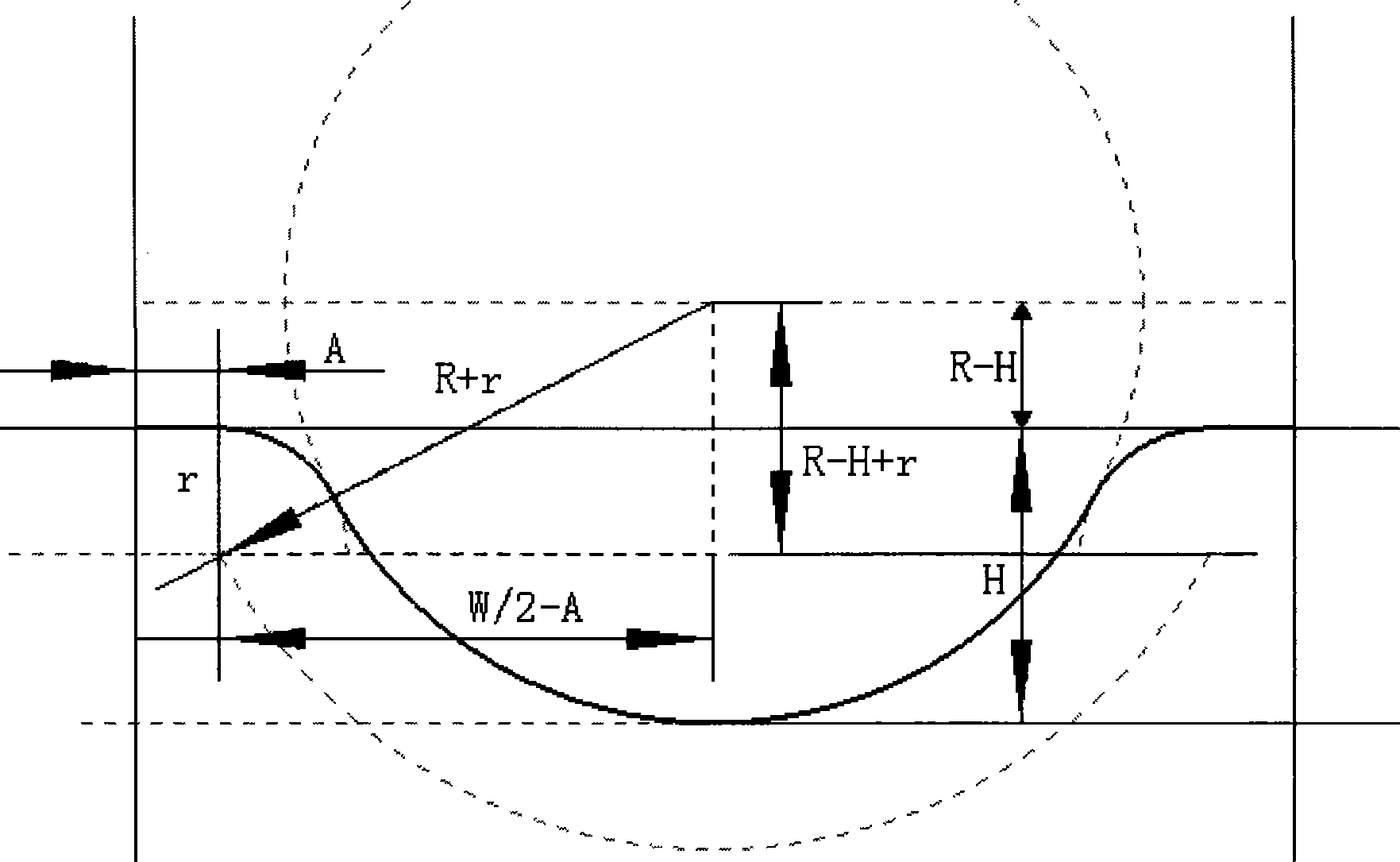

[0030] Step 3, changing the circular turning tool, the present invention will according to the blueprint rope groove pitch, groove depth, large circle radius, chamfer radius, start offset angle, lead-in section length and other shape parameters and rough and finish machining speed, X Fill in the processing parameters such as the depth of each layer in the direction, the depth of each layer in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap