Experimental device of 'wet' rotor effect of multi-stage centrifugal pump

A rotor effect and experimental device technology, applied in pumps, pump control, non-variable pumps, etc., can solve the problems of insufficient theoretical and experimental research support, dependence on large ultra-high pressure centrifugal pump units, etc., and improve independent design and production The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

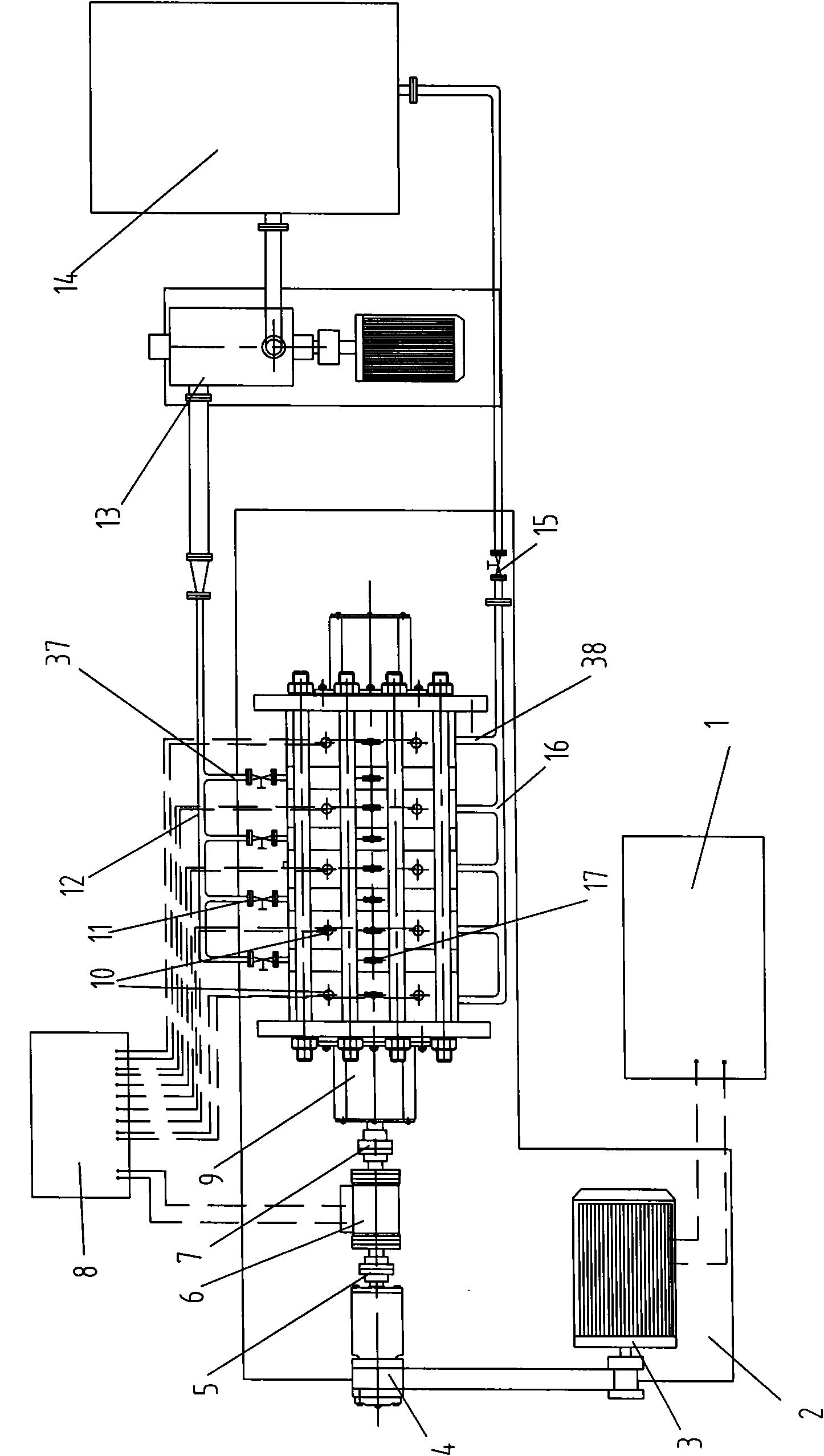

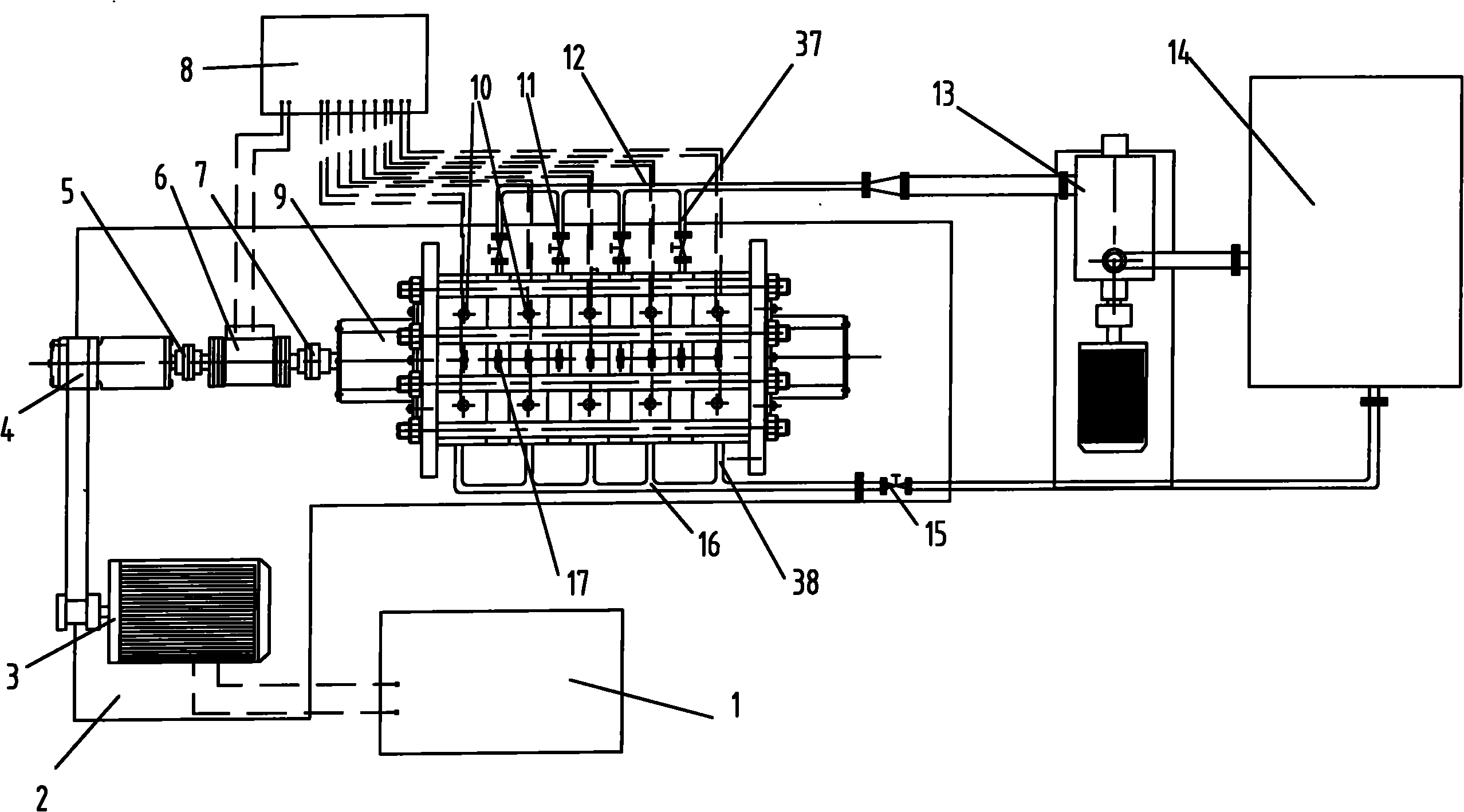

[0020] Embodiment 1, figure 1 and figure 2 Combined with an experimental device for the "wet" rotor effect of a multi-stage centrifugal pump, it includes a pulley speed change device 4 and a drive motor 3 arranged on the base 2 of the test bench, as well as a motor frequency conversion control cabinet 1 and a signal acquisition and processing system. 8. A multi-stage wet rotor table 9 and a pressure cycle system for simulating the working state of the seal between stages of a real multi-stage pump.

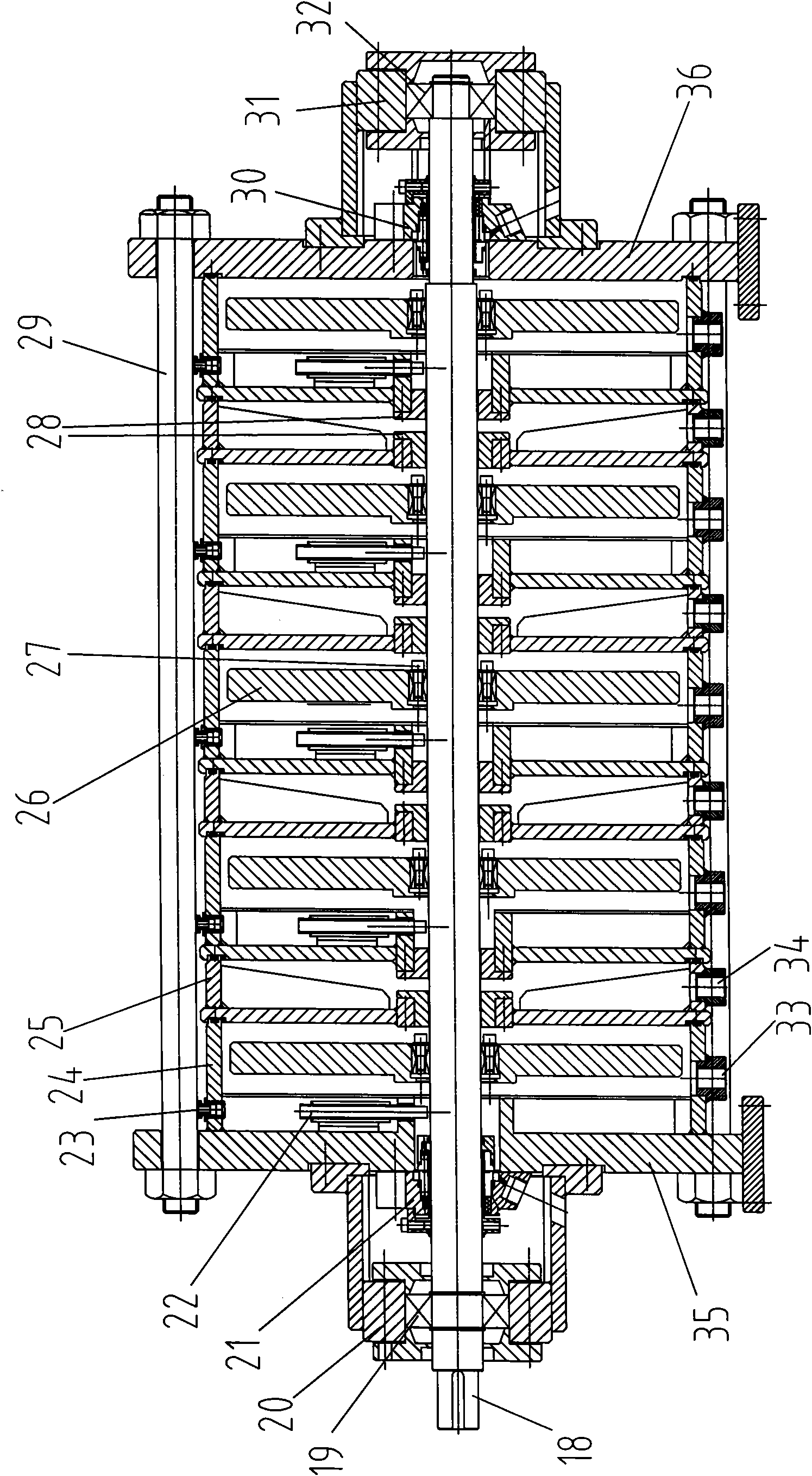

[0021] The multi-stage wet rotor table 9 includes a pressure-bearing shell with 5 stages of rotor segments inside. Each rotor segment is composed of a high-pressure chamber 25 and a low-pressure chamber 24, and each low-pressure chamber 24 is respectively provided with a pump rotor 26; Since a high-pressure chamber 25 is arranged between every two low-pressure chambers 24, five low-pressure chambers 24 and four high-pressure chambers 25 are arranged in the pressure-bearing housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com