Wringing mop

A mop and fixed surface technology, applied in the field of tools for wet wiping floors, can solve the problems of easily hurting arm muscles and bones, thick water traces left on the floor surface, affecting the service life of the floor, etc., so as to overcome the poor water squeeze effect and improve the water squeeze effect, the effect of improving the water squeezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

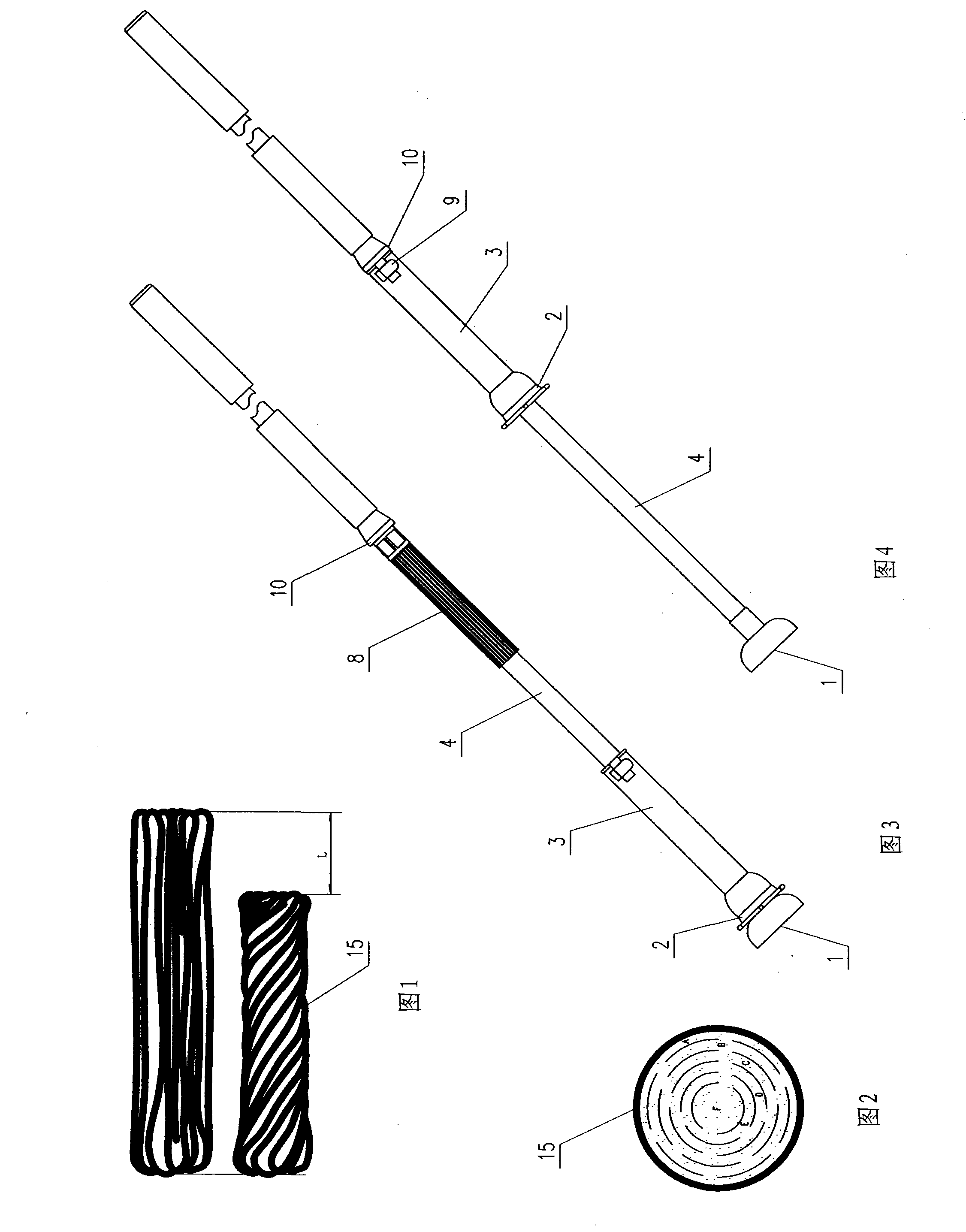

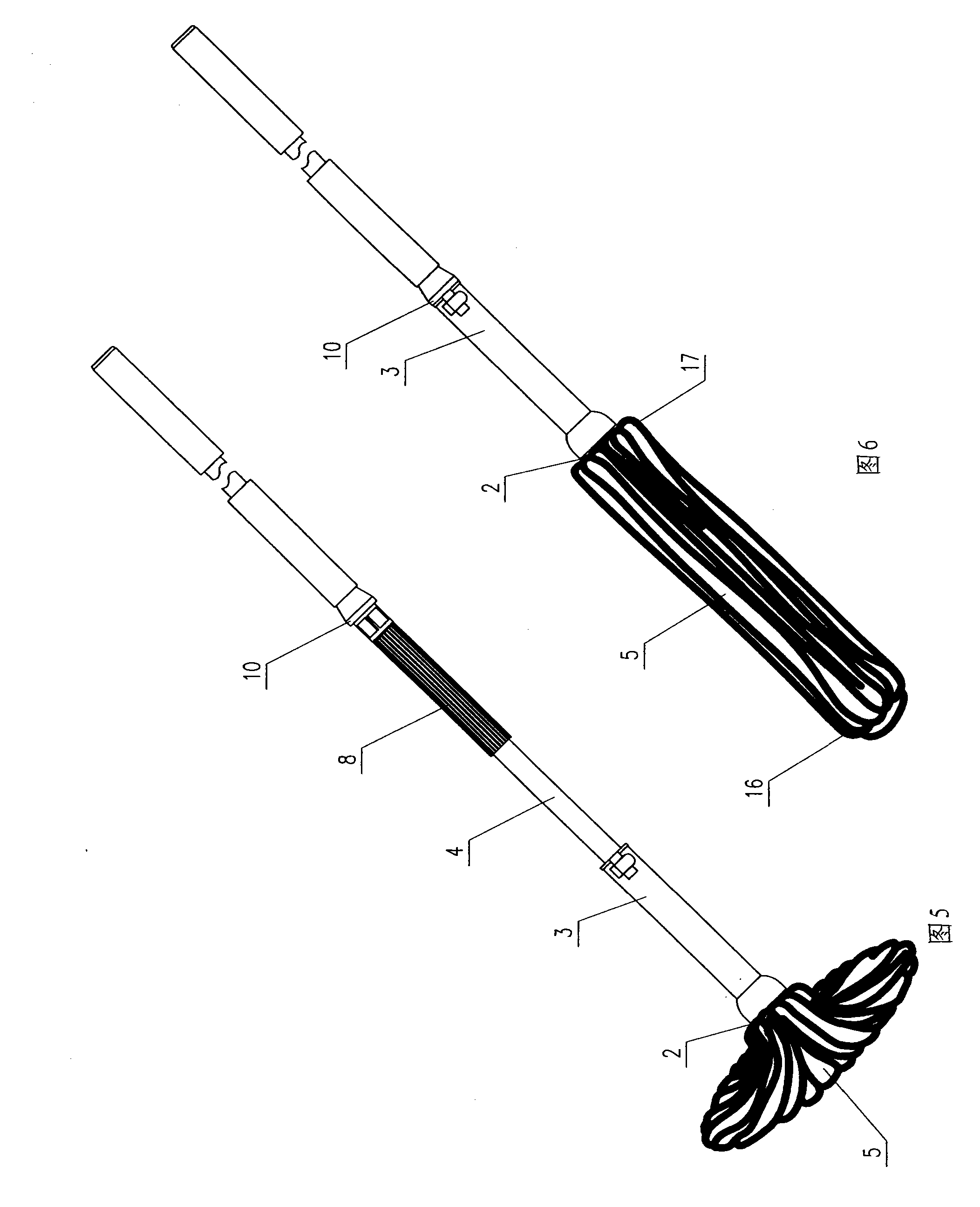

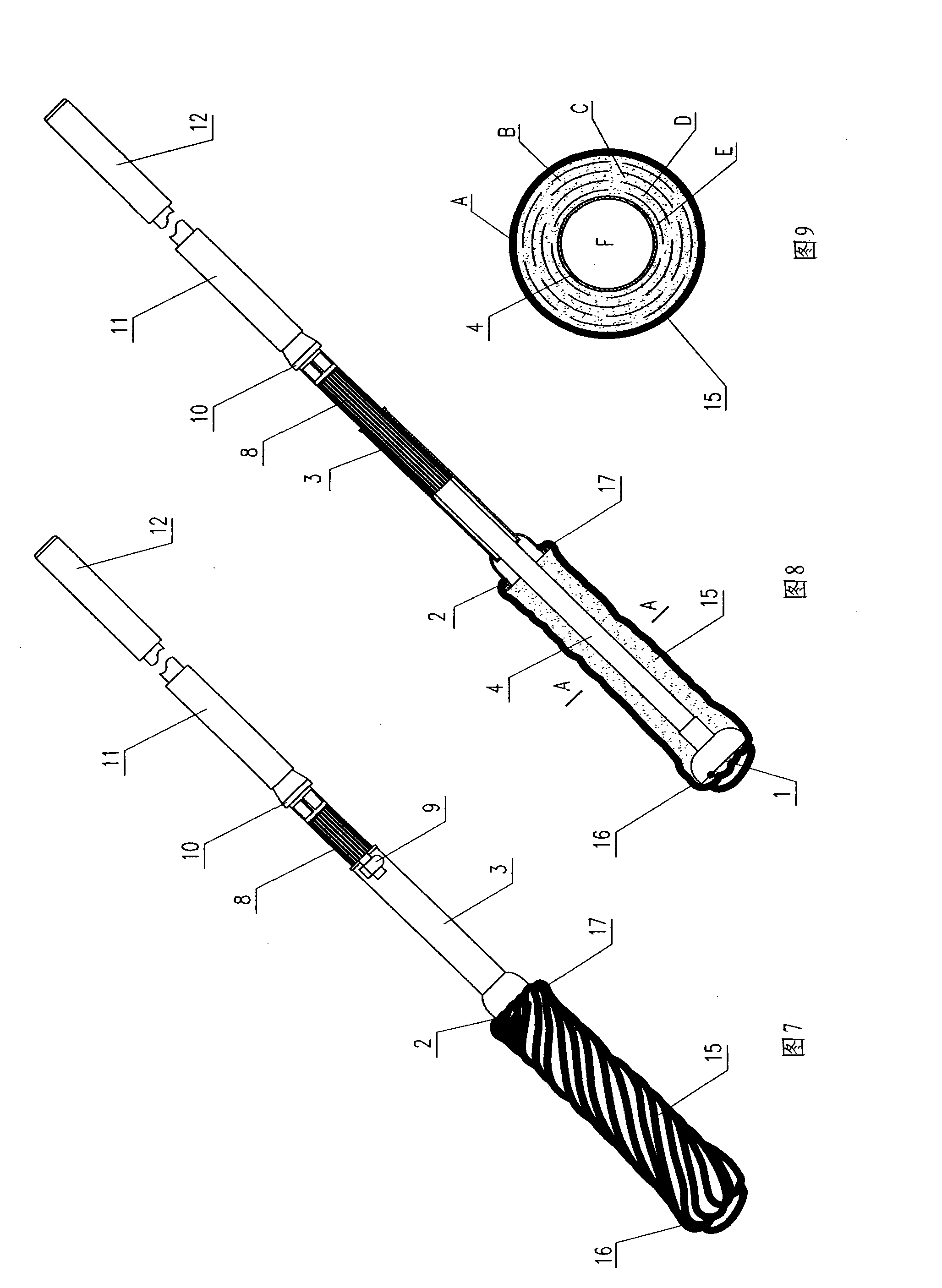

[0035] The present invention will be further described below in conjunction with accompanying drawing and embodiment, introduce first embodiment first, see Figure 10 to Figure 16, a squeeze mop, comprising a rod 4, a straight pocket mop assembly 5 assembled from strings, a point-type fixing surface 1 fixed at one end of the rod 4, a ring-type fixing surface 2, and a On the rod 4 and the sliding sleeve 3 that can move along the axis of the rod 4, the pocket bottom end 16 of the straight pocket-shaped mop assembly 5 is connected with the point-type fixed surface 1, and the pocket end 17 of the straight pocket-shaped mop assembly 5 is fixed with the ring type. Face 2 is connected, see Figure 15 , also includes a piston 13 coaxially arranged between the point-type fixed surface 1 and the rod 4, see Figure 13 , including a cylinder 6 coaxially arranged between the ring-type fixed surface 2 and the sliding sleeve 3, see Figure 12 , the length of cylinder 6 is adapted to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com