Method for preparing hygroscopic film

A film and polyvinyl alcohol technology, applied in the field of moisture absorption, can solve problems such as unsatisfactory moisture absorption performance, and achieve the effect of simple operation and good moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the invention discloses a method for preparing a hygroscopic film to improve the hygroscopic performance of the material.

[0027] The invention provides a method for preparing a hygroscopic film, comprising:

[0028] mixing polyvinyl alcohol, glycerin and water to obtain a mixture, and heating the mixture to obtain a colloid;

[0029] Add polymethacrylic acid in the colloid, fully react;

[0030] The fully reacted product is scraped into a film and dried to prepare a hygroscopic film.

[0031] Polyvinyl alcohol is a polyhydric polymer, which can easily catch the gaseous water molecules in the air to achieve the purpose of moisture absorption. For polyvinyl alcohol, it is preferable to choose polyvinyl alcohol grades with very good water solubility, such as polyvinyl alcohol 1788, but not limited thereto, which is conducive to the preparation of films;

[0032] The weight ratio of the glycerol to polyvinyl alcohol is preferably 1-5:10, more preferab...

Embodiment 1

[0067] Take 10 grams of polyvinyl alcohol 1788 and put it into a 500 ml beaker, then add 1 gram of glycerin, stir it evenly with a glass rod, then add 70 grams of water to the beaker, stir it evenly with a glass rod while adding water, and then stir it under the condition of stirring Put the beaker on the electric stove and boil for 5 minutes;

[0068] Remove the beaker from the electric stove, add 0.15 g of polymethacrylic acid to the beaker, and stir evenly with a glass rod;

[0069] Then add 0.02 gram of sodium benzoate and stir evenly with a glass rod;

[0070] After resting the beaker for 30 minutes, take out part of the colloid in the beaker and put it on a glass plate, scrape and coat the colloid on the glass plate with a triangular plate to form a film, then put the glass plate in an oven at 100°C and dry it for 4 hours. The film on the glass plate is peeled off slowly to form a polyvinyl alcohol hygroscopic film.

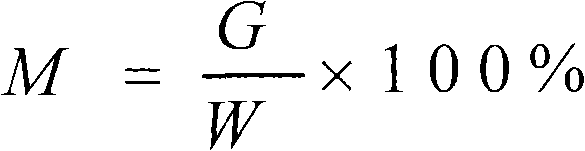

[0071] The film had a moisture absorption capacity ...

Embodiment 2

[0073] Take 10 grams of polyvinyl alcohol 1788 and put it into a 500 ml beaker, then add 1 gram of glycerin, stir evenly with a glass rod, then add 0.05 g of n-octanol and 70 g of water to the beaker, and stir evenly with a glass rod while adding water , and then put the beaker on the electric stove and boil for 5 minutes under the condition of stirring;

[0074] Remove the beaker from the electric stove, add 0.15 g of polymethacrylic acid to the beaker, and stir evenly with a glass rod;

[0075] Then add 0.02 gram of sodium benzoate and stir evenly with a glass rod;

[0076] Will The molecular sieve pulverization made 100 mesh molecular sieve powder;

[0077] Add 1 gram of 100-mesh molecular sieve powder into the beaker and stir evenly with a glass rod;

[0078] After resting the beaker for 30 minutes, take out part of the colloid in the beaker and put it on a glass plate, scrape and coat the colloid on the glass plate with a triangular plate to form a film, then put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com