Integral skin interior trim

一种表层、内装的技术,应用在车辆部件、上部结构、建筑物元件等方向,能够解决难贴紧、树脂流漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

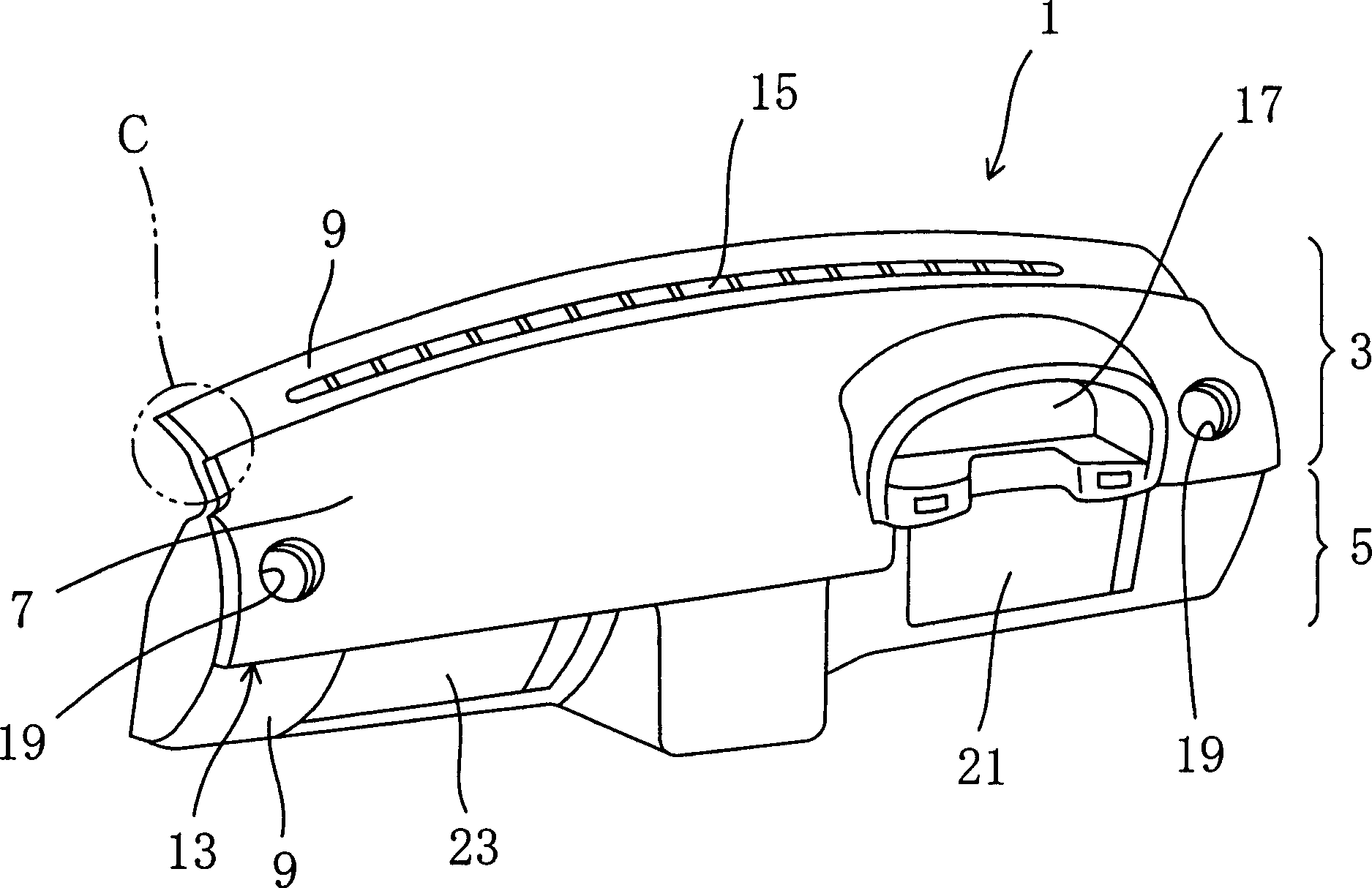

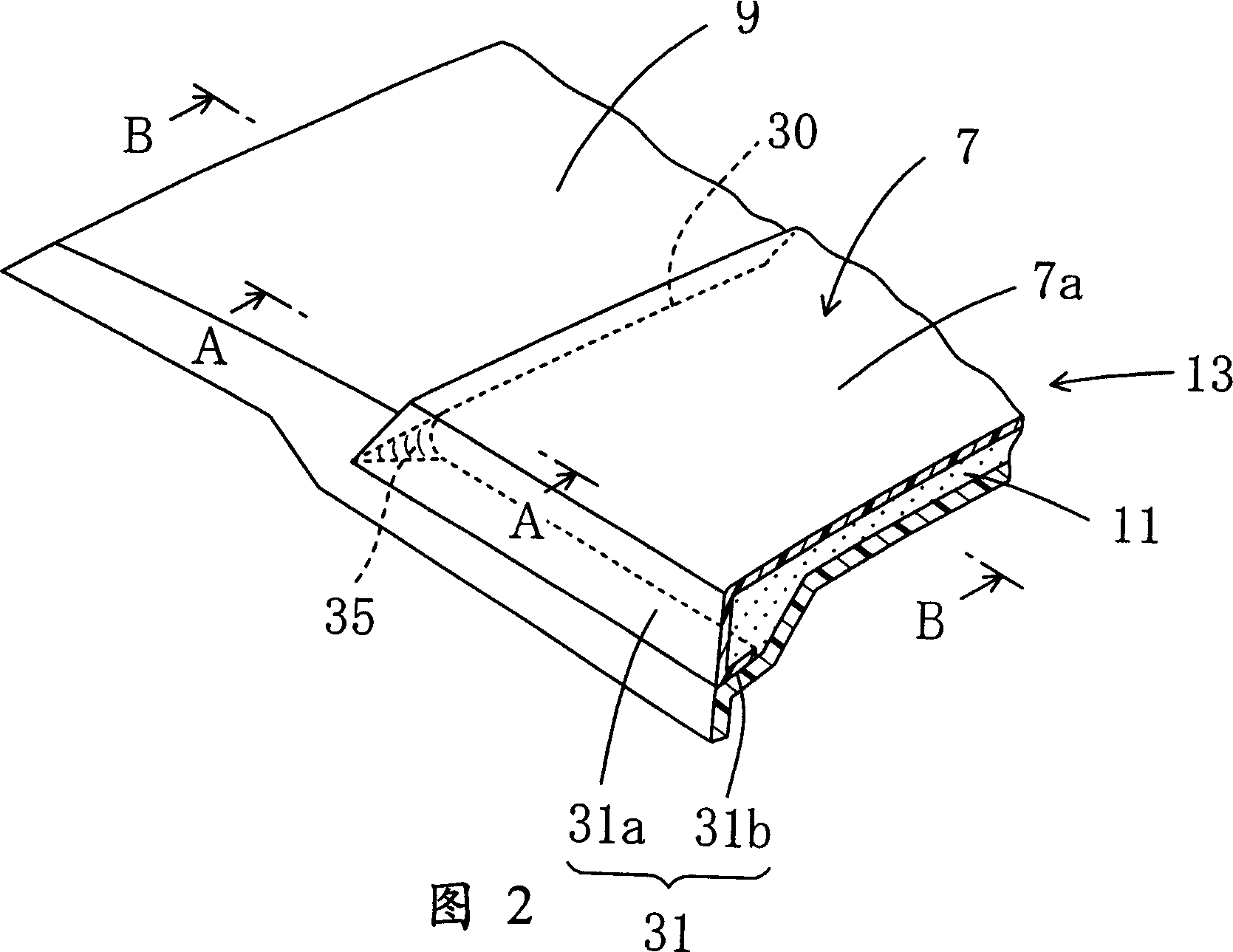

[0036] figure 1 , is a vehicle instrument panel 1 showing an interior member with an integrated surface layer according to Embodiment 1 of the present invention. The instrument panel 1 is composed of an upper panel 3 and a lower panel 5 . The portion of the upper panel 3 excluding the front end edge of the vehicle body constitutes a resin intermediate layer 11 integrally formed between the flexible resin surface layer 7 and the rigid resin base material 9 as shown in FIG. The cushion part 13 of the three-layer structure. The above-mentioned vehicle body front end edge is a single layer where the base material 9 is exposed on the side inside the vehicle, and a front anti-fog nozzle 15 is formed along the vehicle width direction at this position.

[0037] The above-mentioned flexible resin surface layer 7 is formed of a flexible soft material such as vinyl chloride or thermoplastic (olefine), and is molded into a predetermined shape by vacuum forming, long slit forming, or the...

Embodiment approach 2

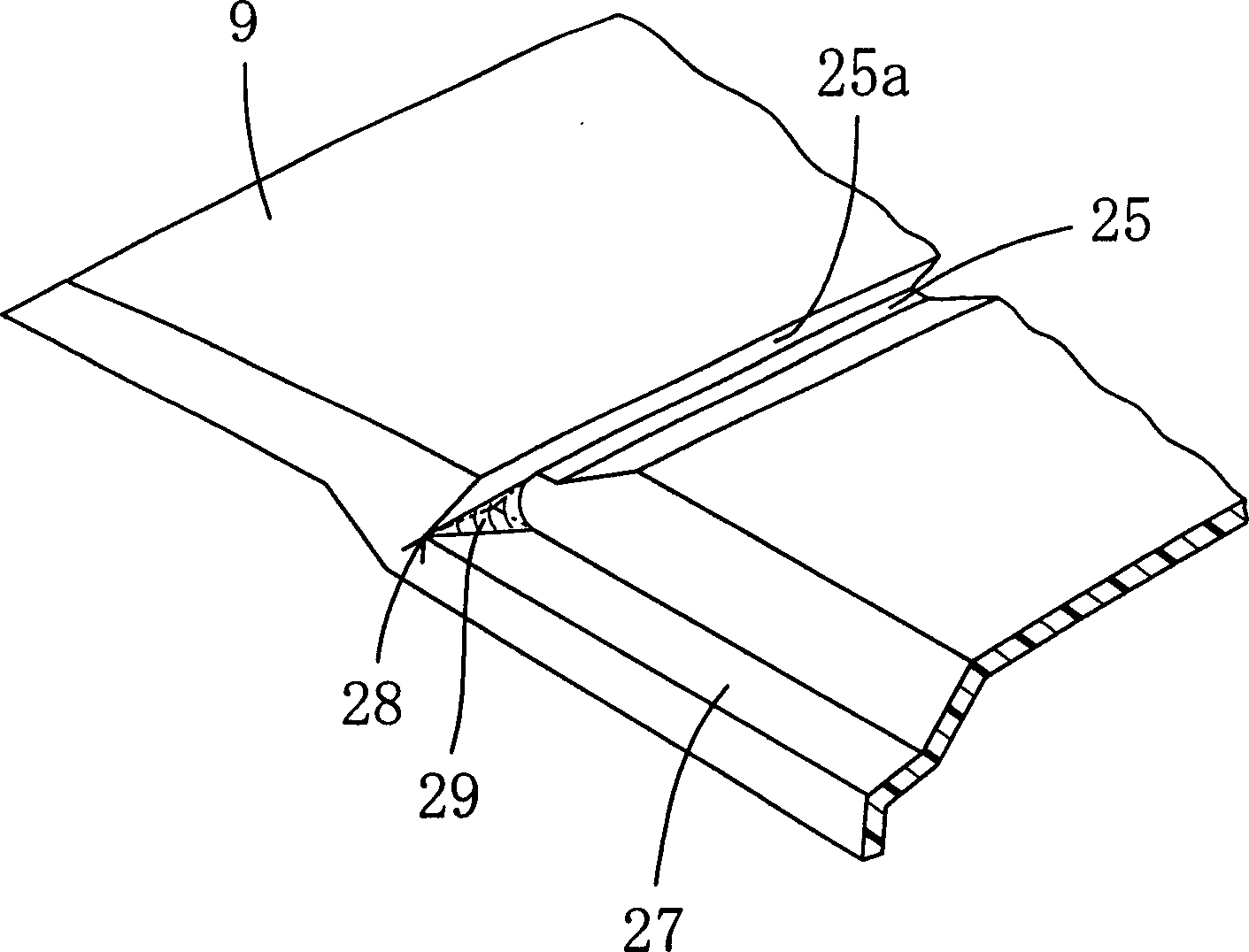

[0048] Embodiment 2 consists of Figure 8 to Figure 10 express. In Embodiment 1, flat surface portions 27 extending from both ends of the groove 25 extending in the vehicle width direction to the rear of the vehicle body are formed on the base material 9 . Instead of the flat surface, in this embodiment, as Figure 9 As shown, a groove 37 similar to the groove 25 described above is provided on the substrate 9 in such a manner as to connect both ends of the groove 25 . On the other hand, the left and right of surface layer 7, such as Figure 10 As shown (only the left side is shown in the figure), the lower flange is not provided and only the side cover 31 is provided so that it contacts as Figure 8 The side wall surface of the groove 37 of the base material 9 as shown, that is, the cover pressing surface 37a.

[0049] and, if Figure 9 As shown, a scalloped corner portion 29 is formed at a corner portion 28 formed by the cover pressing surface 25a on the front side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com