Patents

Literature

39results about How to "Improve vibration damping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-active particle vibration damping device with truss structure

InactiveCN102619293AImprove vibration damping performanceSimple structureShock proofingSteel tubeFrequency band

The invention discloses a semi-active particle vibration damping device with a truss structure. The truss structure is connected with a structure to be damped, the vibration damping device comprises magnetic-permeable metal particles, a coil, a current control module, a vibration pickup sensor and a direct-current power module, the magnetic-permeable metal particles are filled in a hollow steel tube of the truss structure, the coil is wound on the outer wall of the hollow steel tube, the current control module is connected with the coil, the vibration pickup sensor is disposed on the structure to be damped, and the current control module receives vibration signals picked up by the vibration pickup sensor and controls the direct-current signal module to output corresponding current to the coil after the vibration signals are processed. The vibration frequency of the structure to be damped can be tracked, the optimal damping ratio of a particle damper can be quickly adjusted, and accordingly the vibration attenuation performance of the semi-active particle vibration damping device within a broader frequency band range is improved. In addition, the semi-active particle vibration damping device is simple in structure and high in adaptability, and an extra space is omitted.

Owner:JIANGSU UNIV OF SCI & TECH

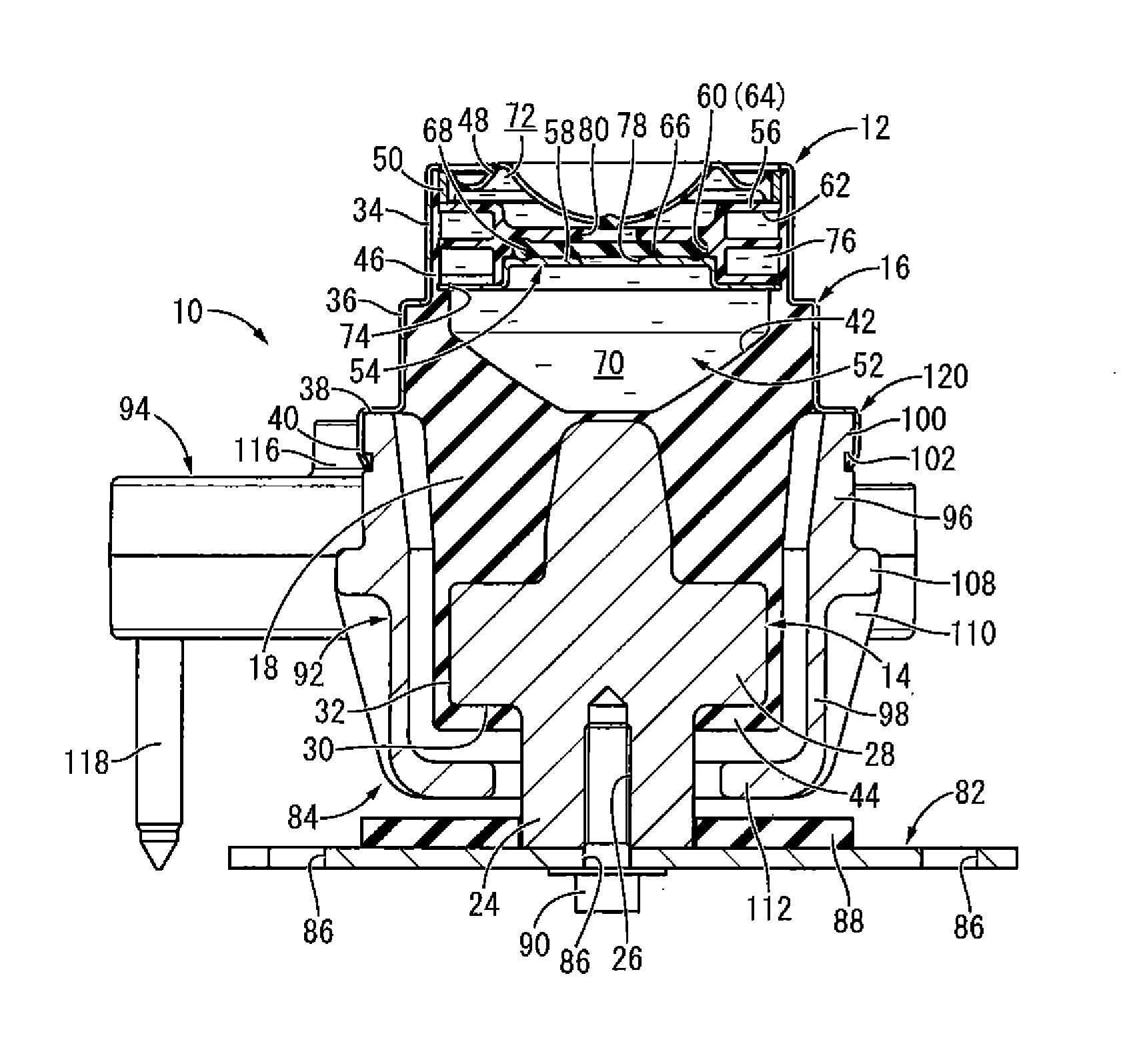

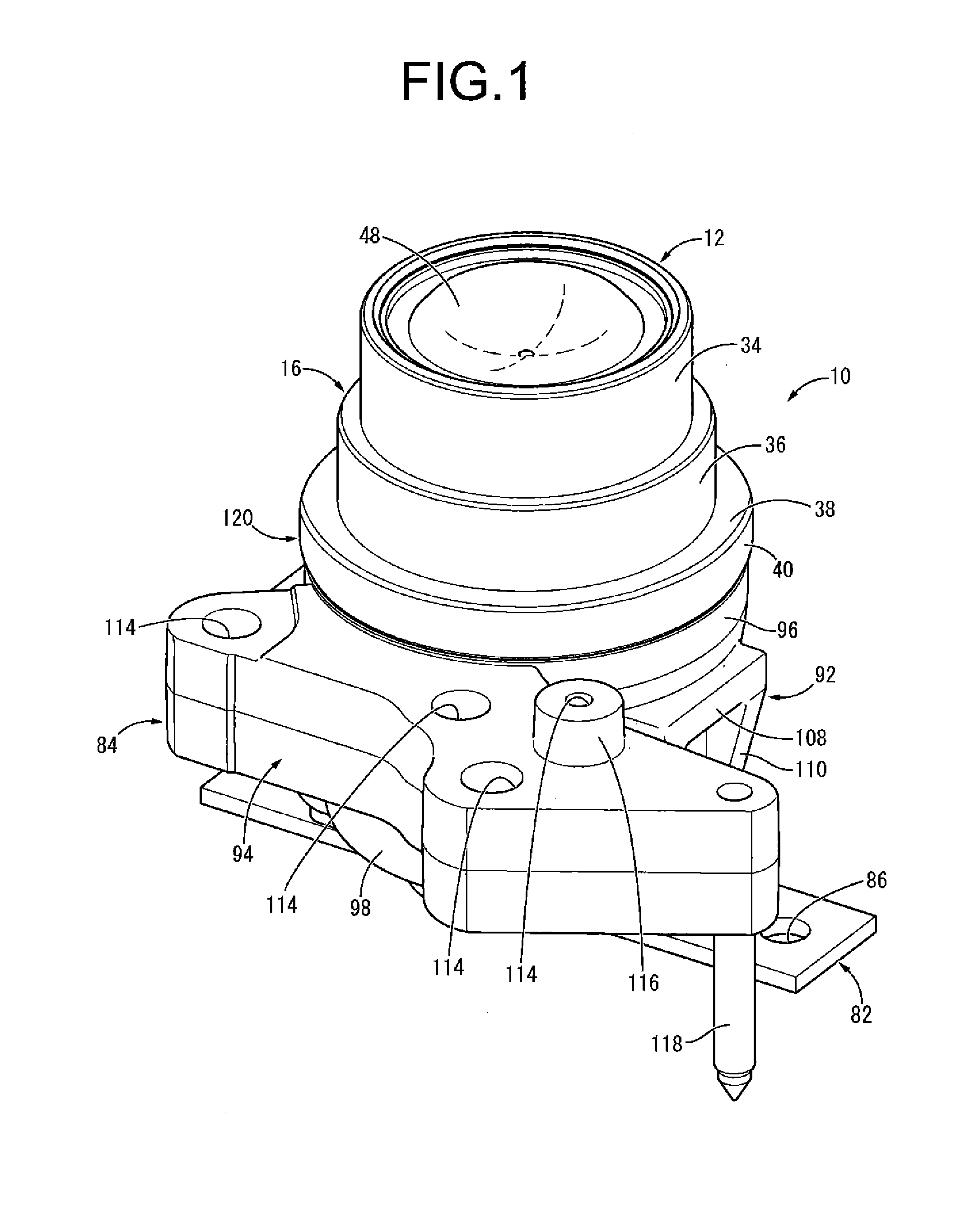

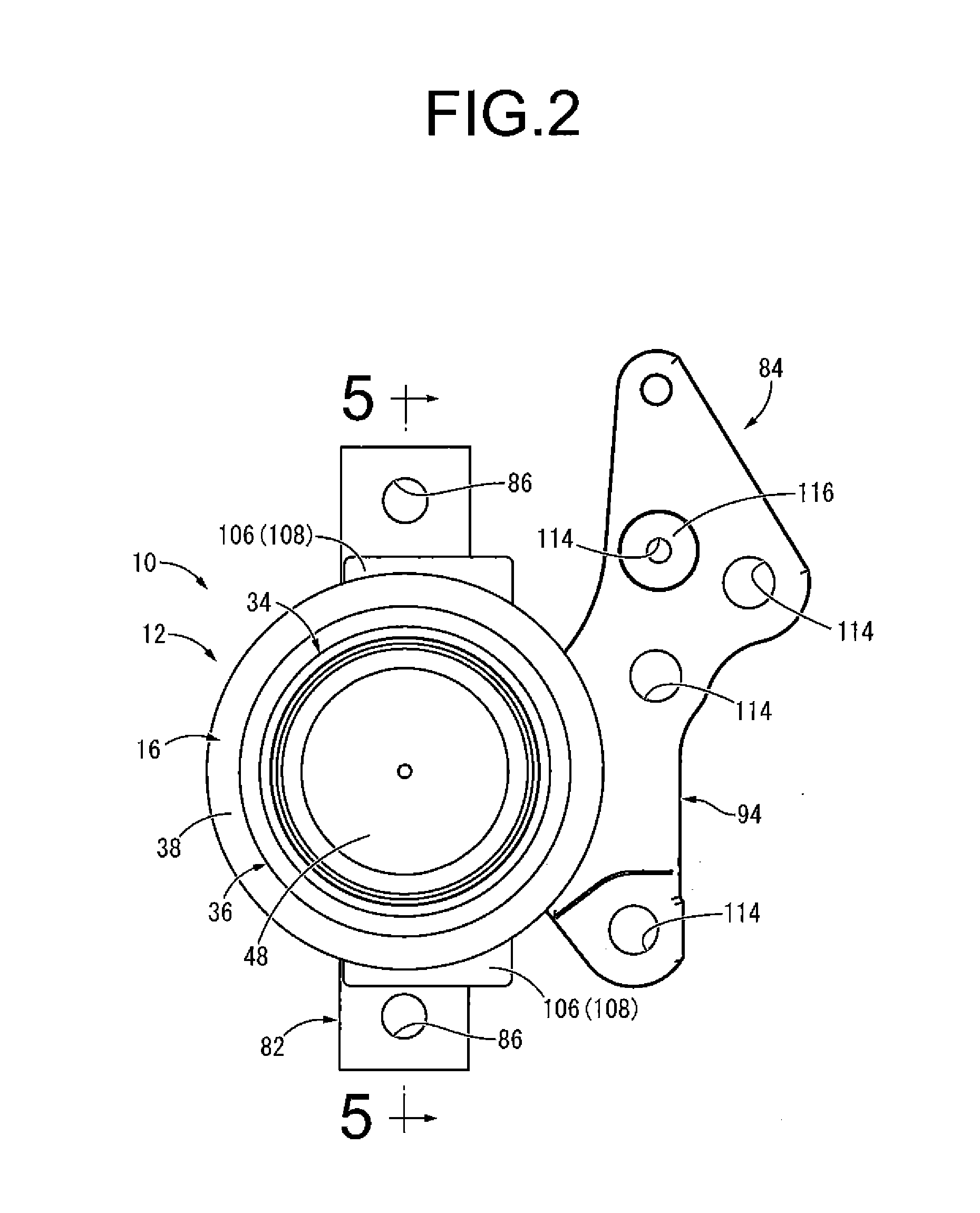

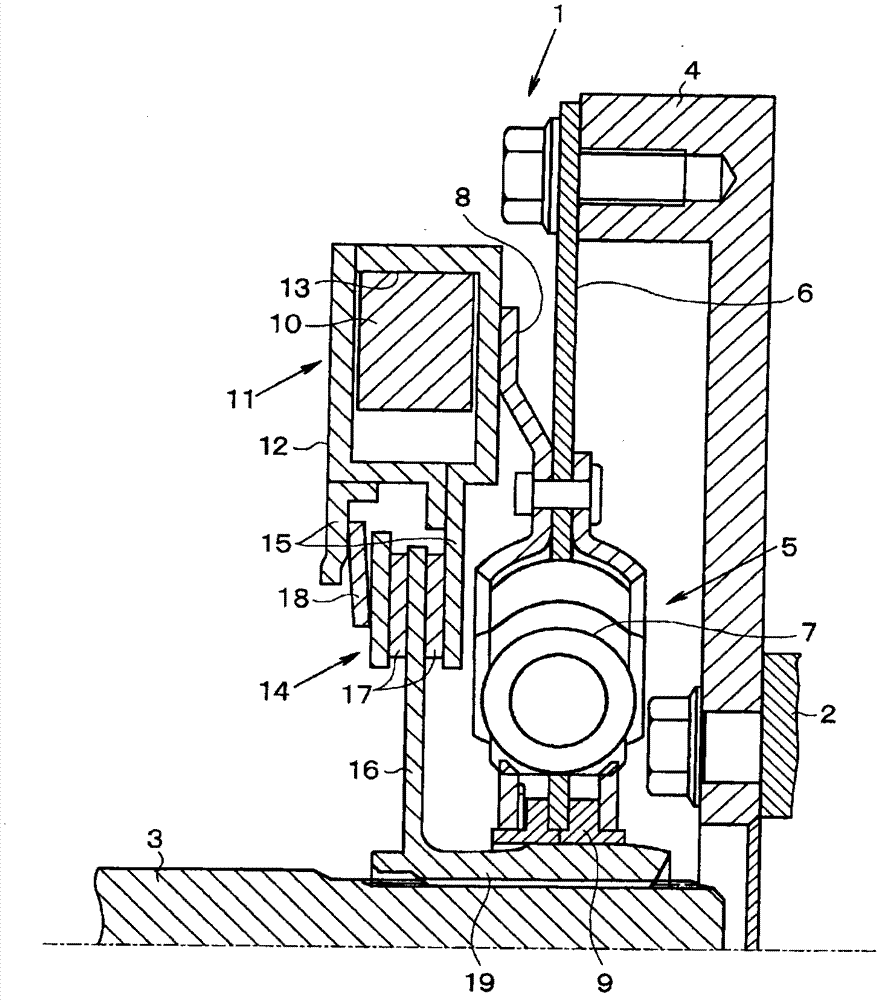

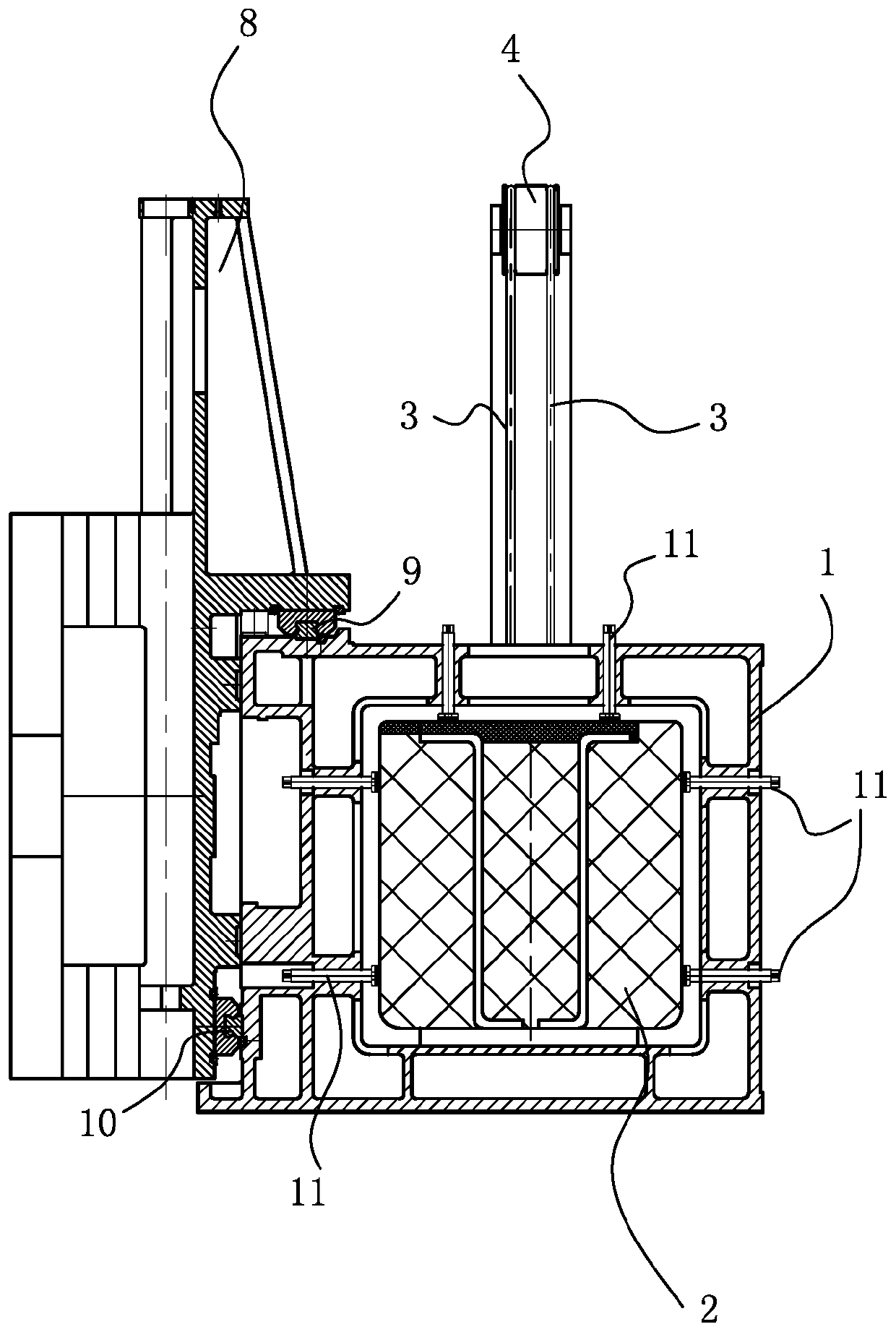

Vibration damping device

ActiveUS20140246558A1Increased load-bearing capacityEfficiently maintaining load bearing performanceSpringsNon-rotating vibration suppressionRelative displacementThumb opposition

A vibration damping device including a first mounting member arranged on a lower side of a second mounting member, the first and second mounting members being elastically connected by a main rubber elastic body, and an outer bracket arranged on the lower side of the second mounting member. A coupling part is constituted by engagement between a bottom edge of the second mounting member and a top edge of the outer bracket, and the second mounting member is configured to be attached to a vibration source via the outer bracket. The outer bracket is arranged in opposition to the first mounting member in an axis-perpendicular direction, and an axis-perpendicular stopper member that regulates relative displacement between the first and second mounting members in the axis-perpendicular direction is constituted by contact between the first mounting member and the outer bracket.

Owner:SUMITOMO RIKO CO LTD

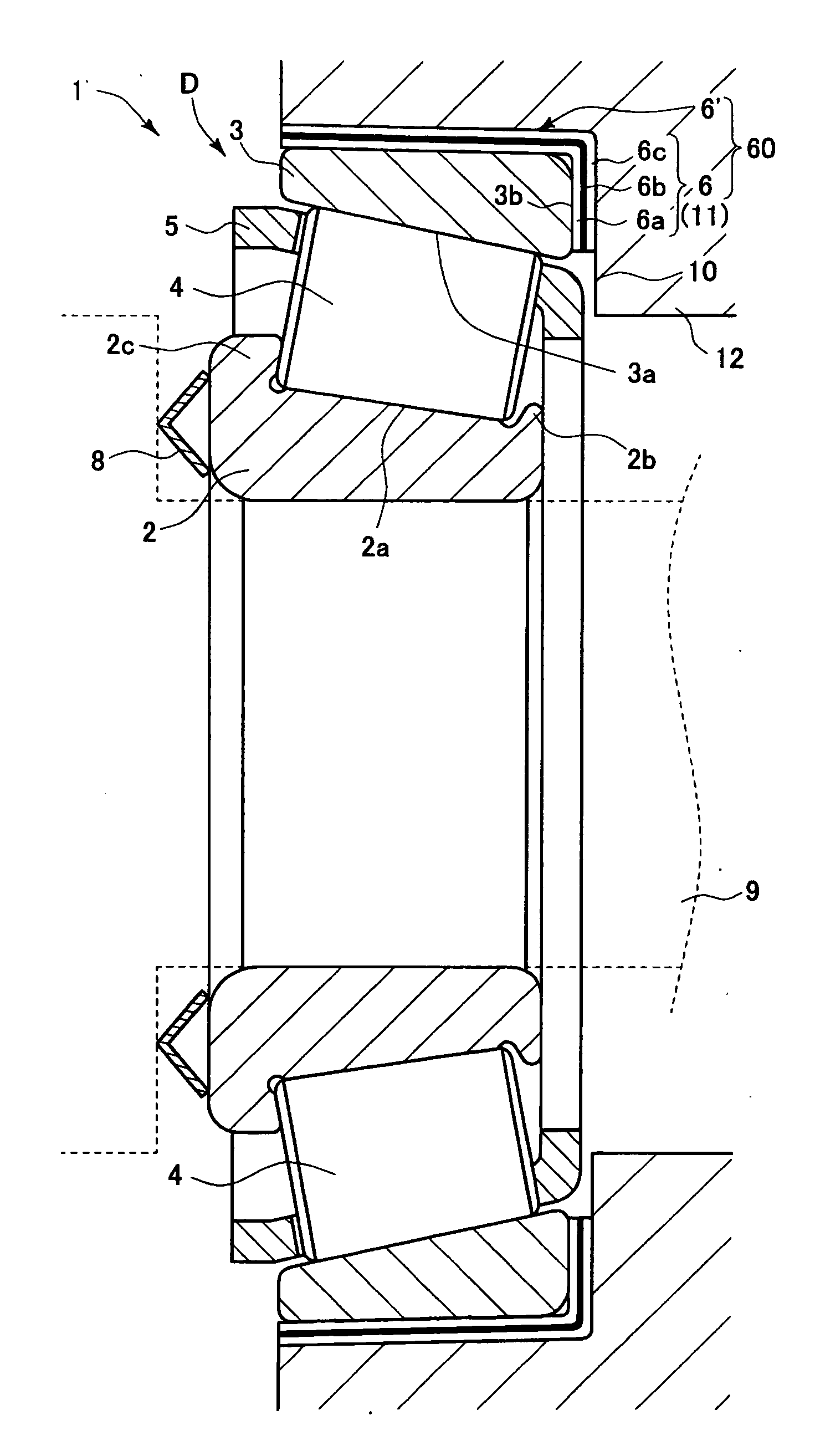

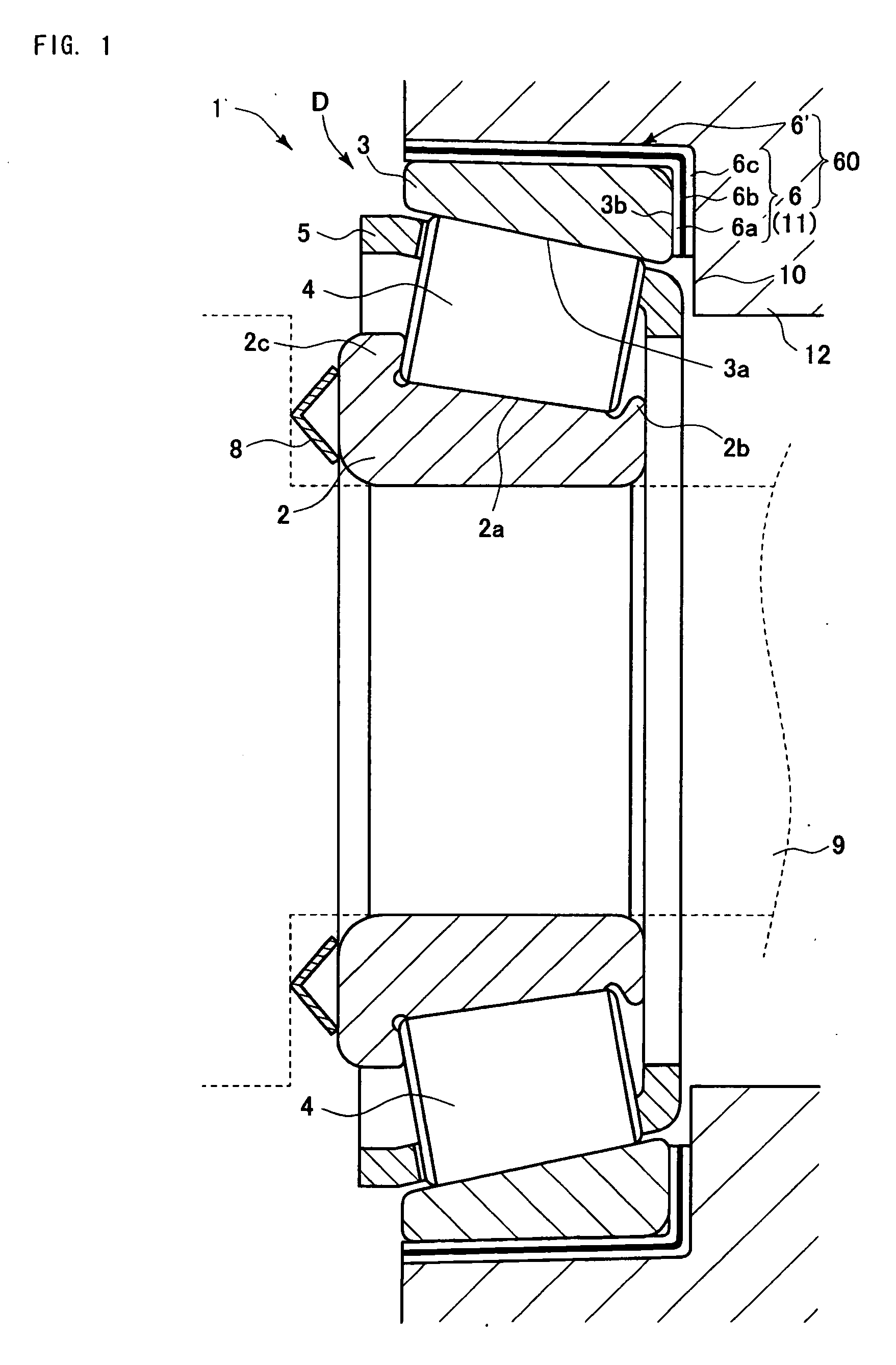

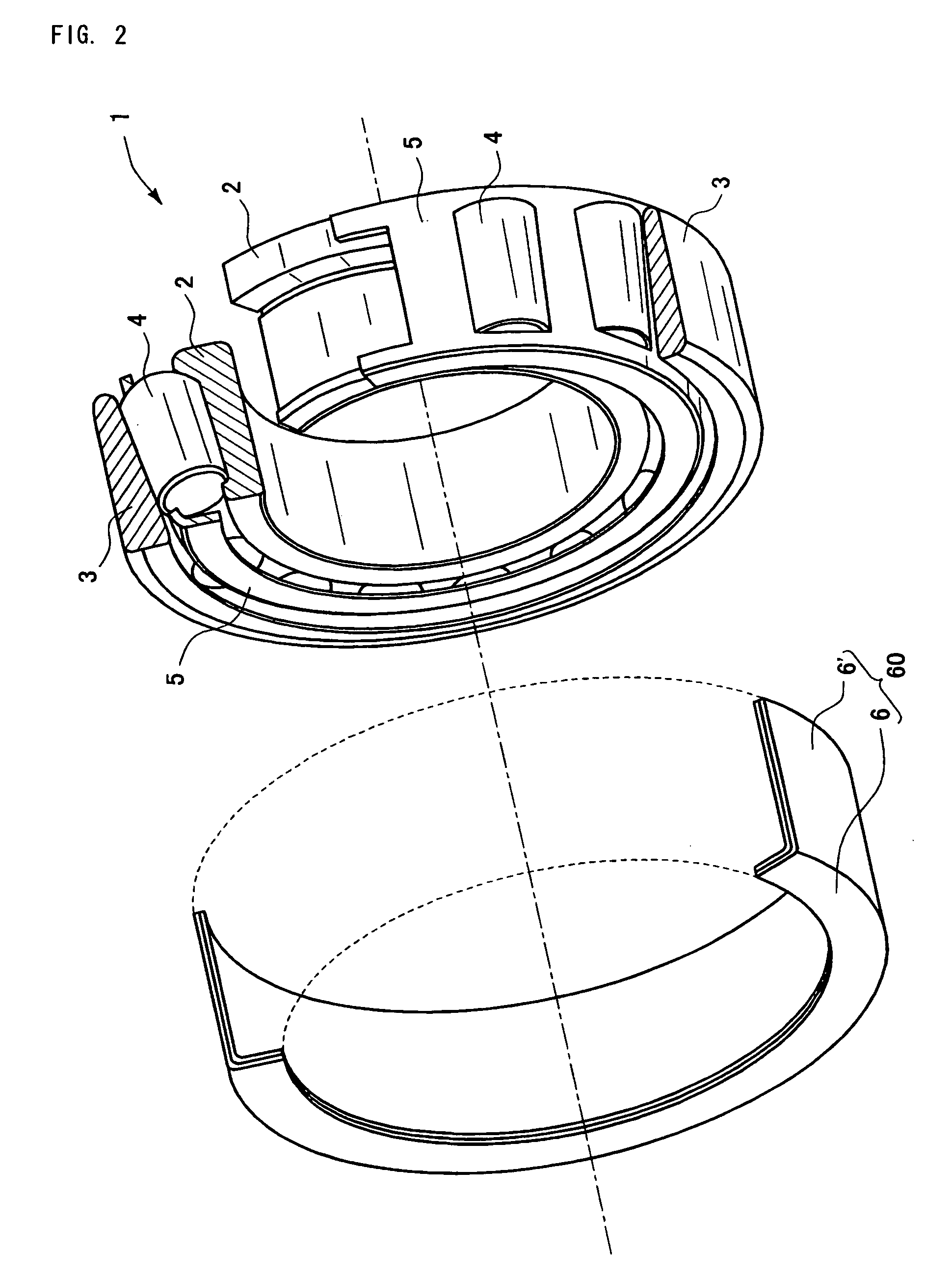

Rolling bearing device

InactiveUS20080253710A1Improve rigidityImprove vibration damping performanceRoller bearingsElastic bearingsRolling-element bearingEngineering

The rolling bearing includes an inner ring, and an outer ring which is arranged in a concave part which is formed in a fixing member so as not to rotate in a state preloaded in an axial direction toward the inner ring by way of a rolling element, with the fixing member at a bottom surface of the concave part. Moreover, a vibration isolating part formed of a laminated body including a pair of metal layers and a resin layer which is thinner than these metal layers and interposed between them is press clamped to be disposed between an end surface of the outer ring at a preloaded side in the axial direction and the bottom surface of the concave part, in such a manner that a direction of lamination may coincide with the axial direction.

Owner:JTEKT CORP

Noise damping composition

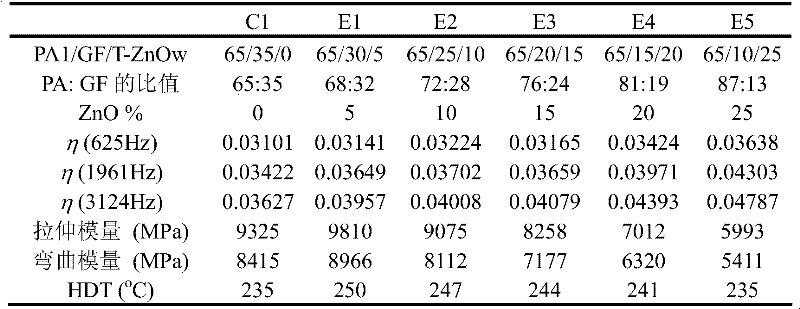

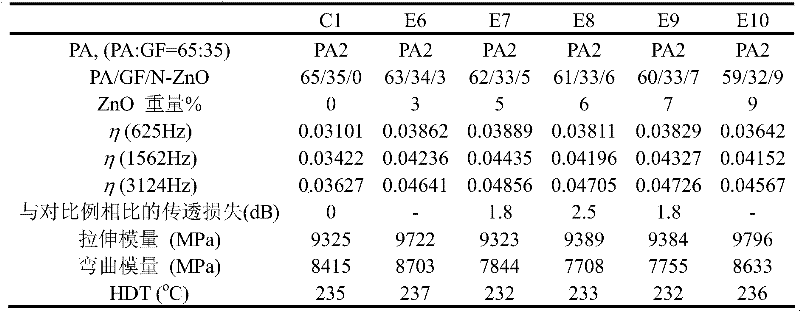

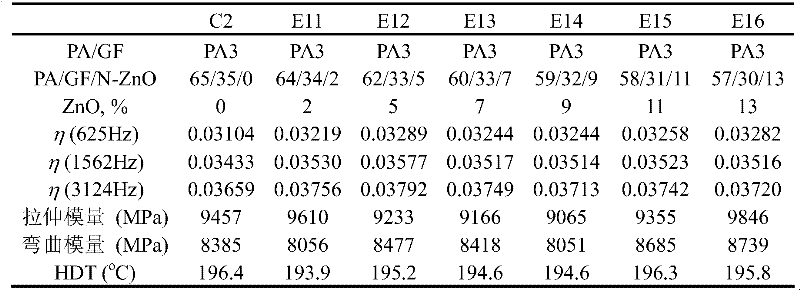

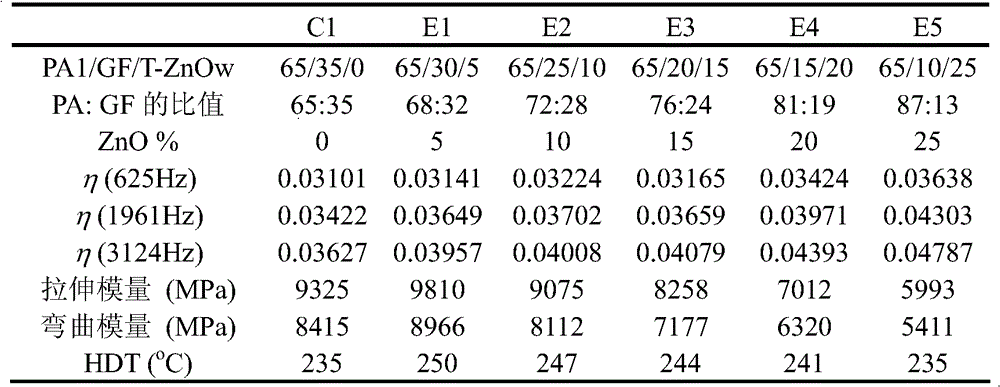

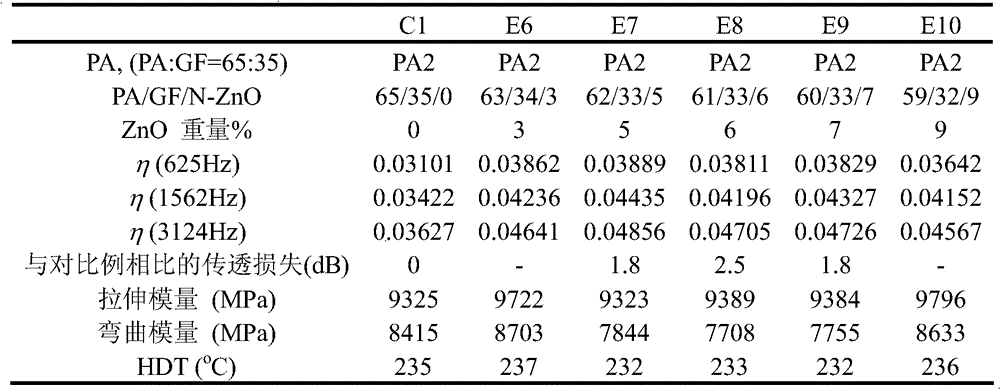

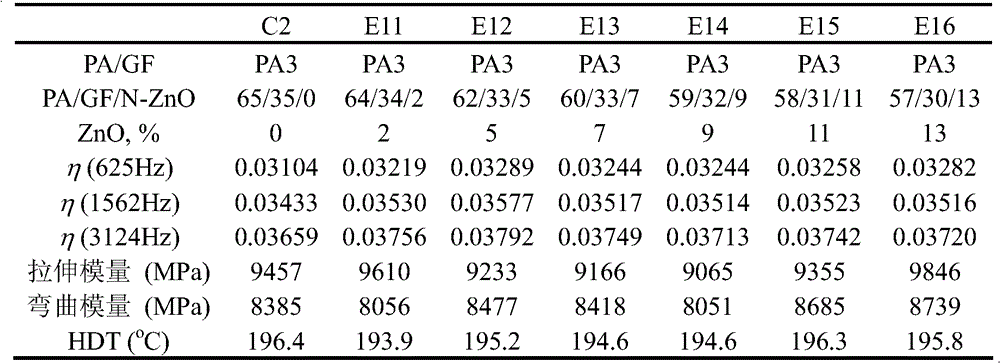

InactiveCN102558840AImprove vibration damping performanceEnhanced inhibitory effectMaterial nanotechnologyPolymer sciencePolyamide

The invention relates to a noise damping composition, and in particular discloses a thermoplastic composition with excellent vibration damping performance and noise inhibition performance and a molded product prepared from the thermoplastic composition. The molded product can be produced in low cost. The noise damping composition contains (a) about 50 to 85 weight percent of polyamide, (b) about 5 to 45 weight percent of fiber reinforcing agent, (c) about 1 to 25 weight percent of zinc oxide and (d) about 0 to 15 weight percent of other additives on the basis of the total weight of the noise damping composition, wherein the noise damping composition does not contain a flame retardant basically.

Owner:EI DU PONT DE NEMOURS & CO

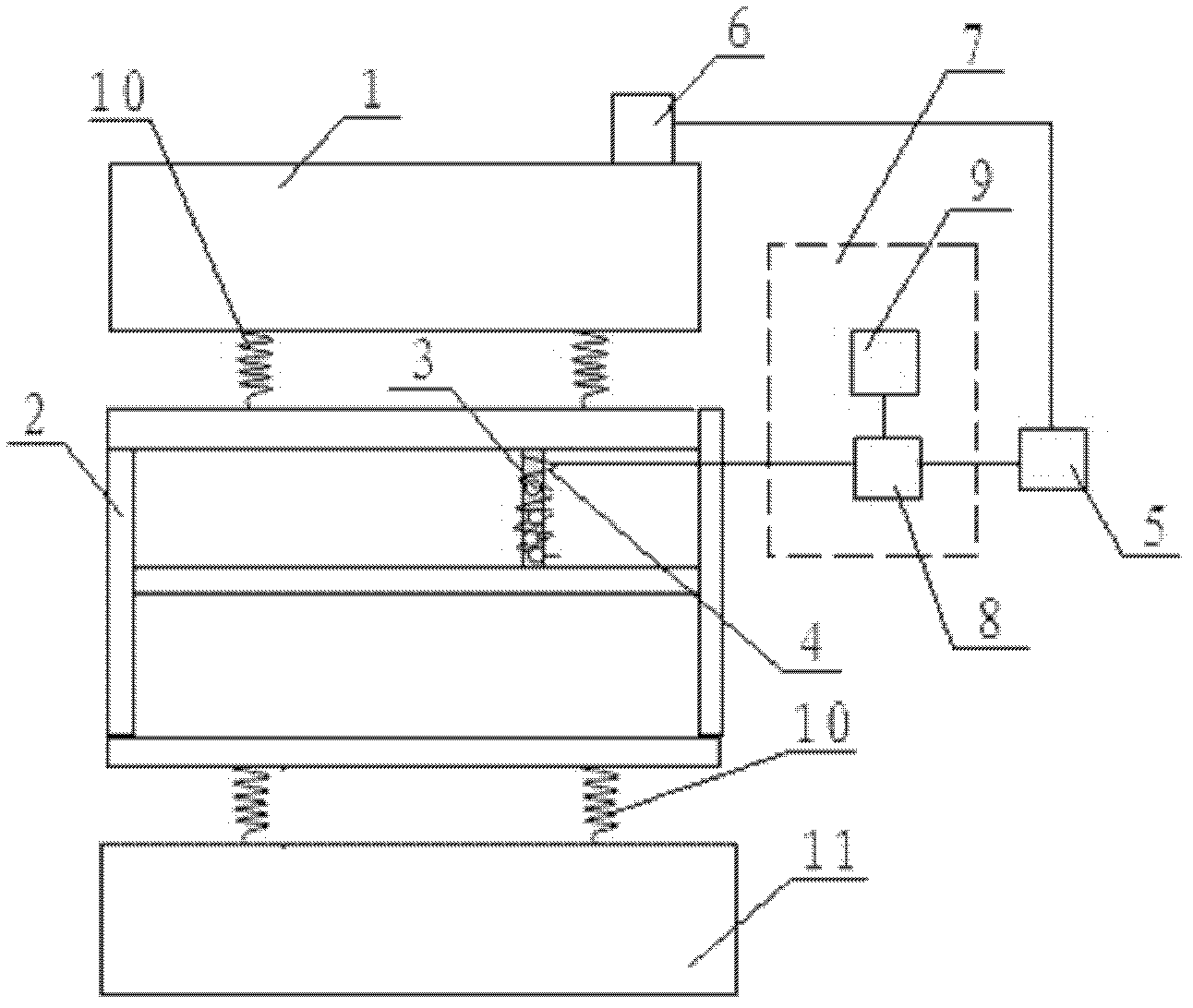

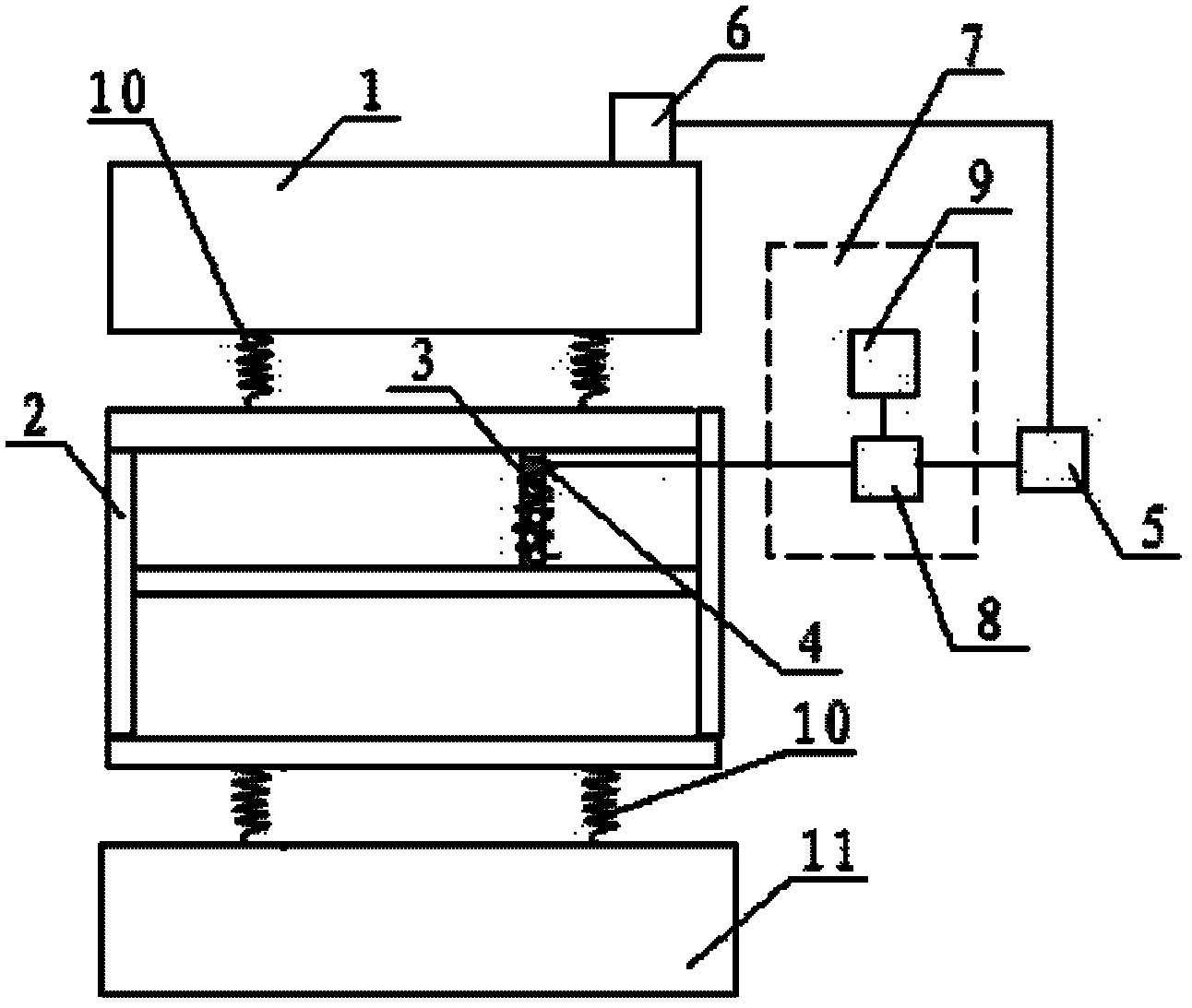

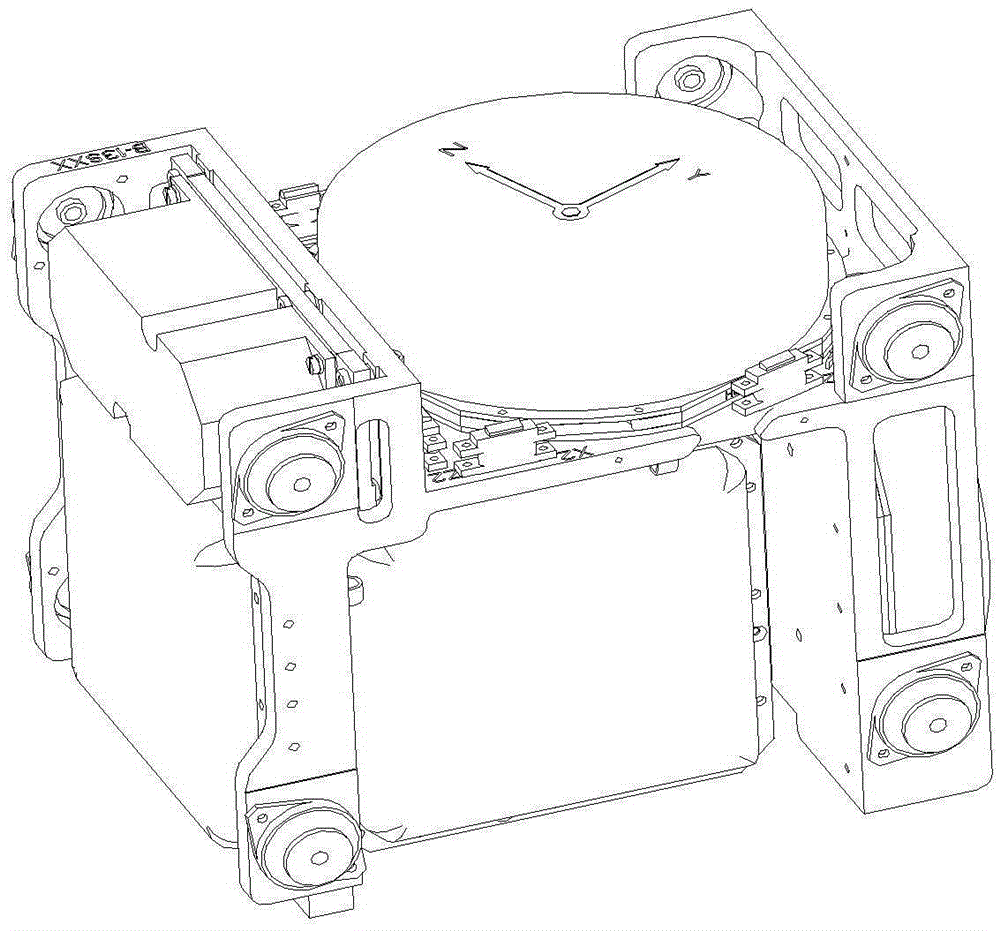

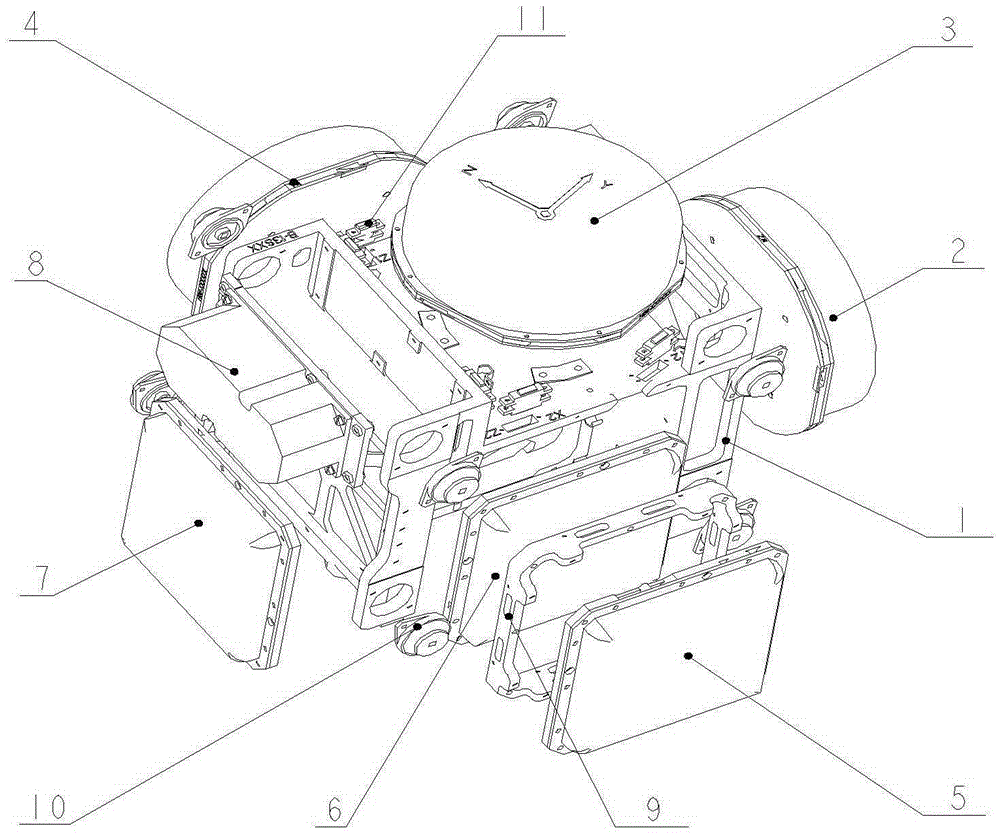

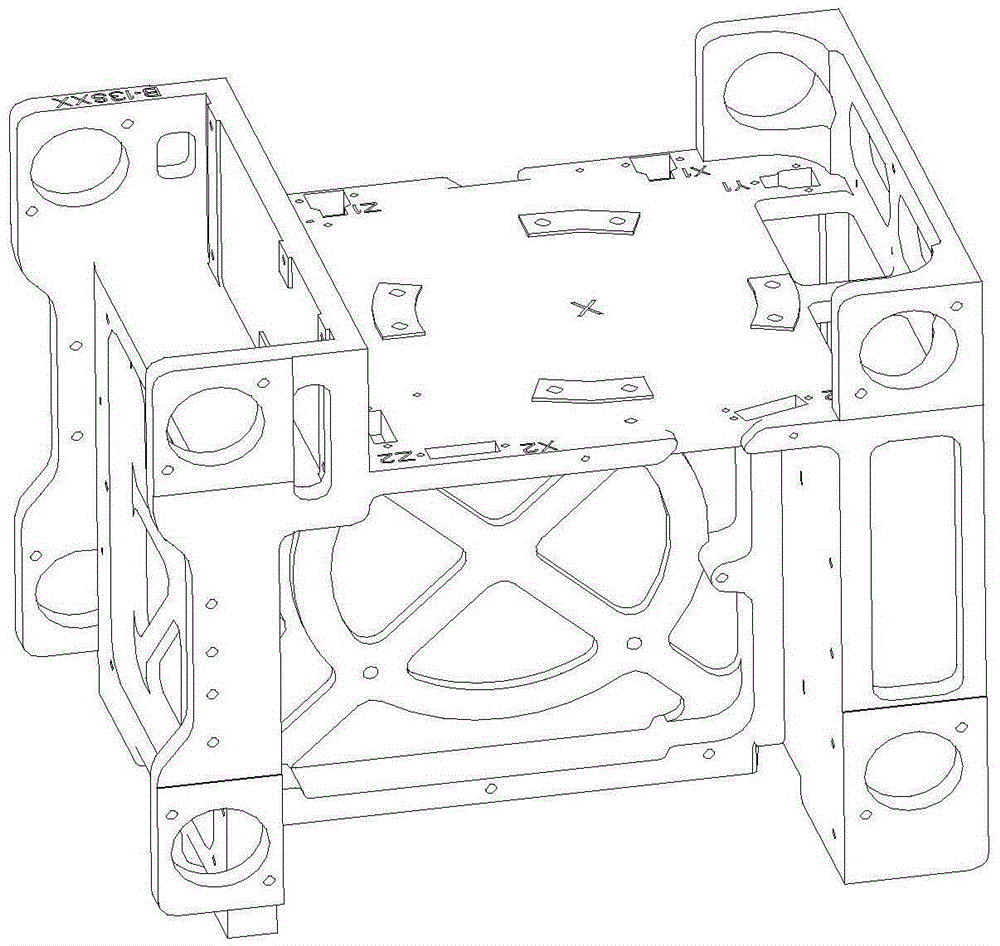

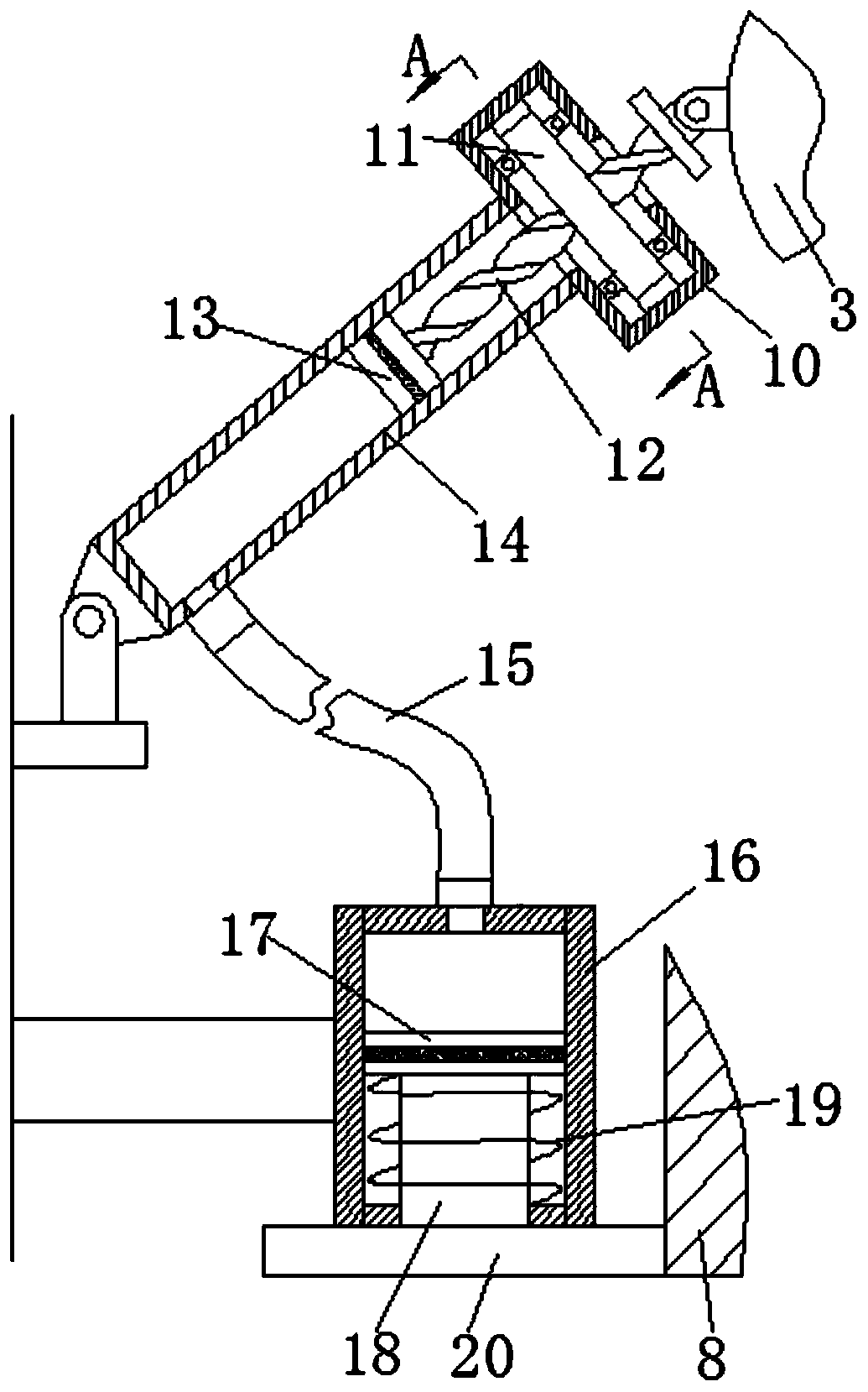

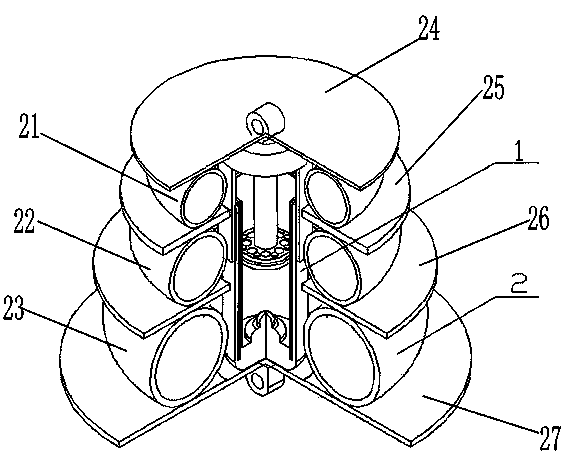

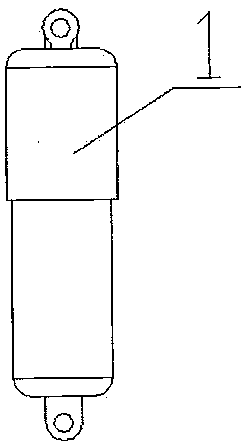

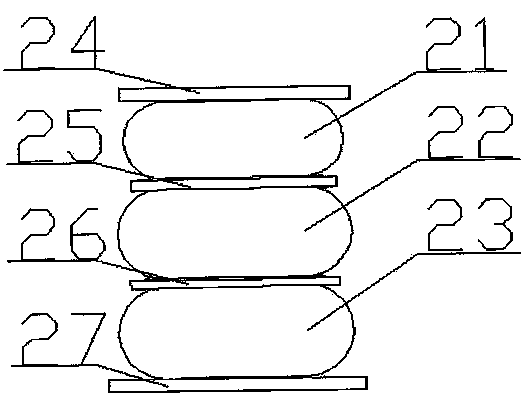

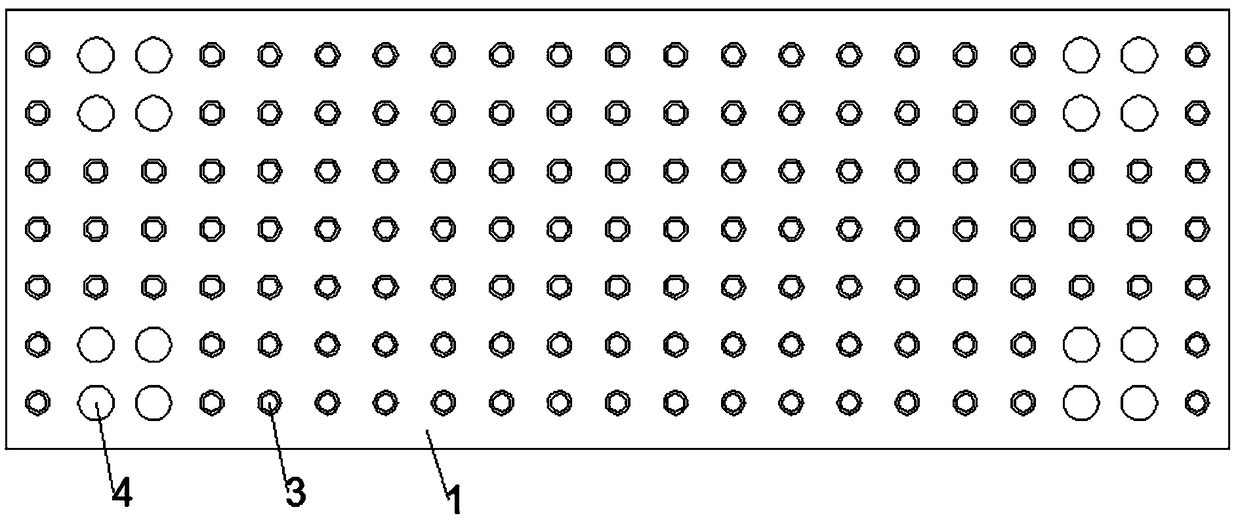

Triaxial optical fiber gyro structure taking eight-point vibration reduction and accelerometer heat-insulation measures

ActiveCN105403212AImprove vibration damping performanceImprove consistencySagnac effect gyrometersHeating timeFibre optic gyroscope

A triaxial optical fiber gyro structure taking eight-point vibration reduction and accelerometer heat-insulation measures comprises a body (1), a first gyro (2), a second gyro (3), a third gyro (4), a first circuit box (5), a second circuit box (6), a third circuit box (7), an accelerometer assembly (8), a circuit box installing supports (9) and vibration reducers (10). The body (1) is a hexahedron frame, eight vibration reducers (10) are installed at eight corners of the body (1) respectively, and the balancing is performed through position adjustment of each assembly, so that the geometric center C1 of the eight vibration reducers and the mass center C2 of all components coincide. No counterweight is added in the mass center adjusting process, the occurrence of liner vibration and angular vibration coupling is avoided effectively, and the vibration reduction performance is improved. A heat-insulation gasket and a silica gel layer are adopted for double-layer heat insulation for the accelerometer assembly (8), the starting heating time of the accelerometer assembly is reduced obviously, and the total power consumption of a gyro assembly is lowered.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Vibration damping device

InactiveCN102822562AMinimizes changes in inertial mass balancePrevent or suppress changes in inertial mass balanceRotating vibration suppressionSlip couplingReciprocating motionTransmitted power

Provided is a vibration damping device capable of suppressing variations in the degree of reciprocating movement of a pendulum which is caused by variations in the rotational center of the vibration damping device. The vibration damping device is equipped with a pendulum vibration damping mechanism (11) that includes a mass body (10) that moves in a pendular manner in response to torsional vibrations to dampen the torsional vibrations. An inertial body (4) is provided on the drive power source side of rotation shafts (2, 3). An elastic vibration reducing mechanism (5) is capable of transmitting power to the inertial body (4) and provided more toward the transmission side than the inertial body (4). The pendulum vibration damping mechanism (11) is capable of transmitting power to the elastic vibration reducing mechanism (5) and provided more toward the transmission side than the elastic vibration reducing mechanism (5). A torque limiter mechanism (14) is capable of transmitting power to the pendulum vibration damping mechanism (11) and provided more toward the transmission side than the pendulum vibration damping mechanism (11).

Owner:TOYOTA JIDOSHA KK

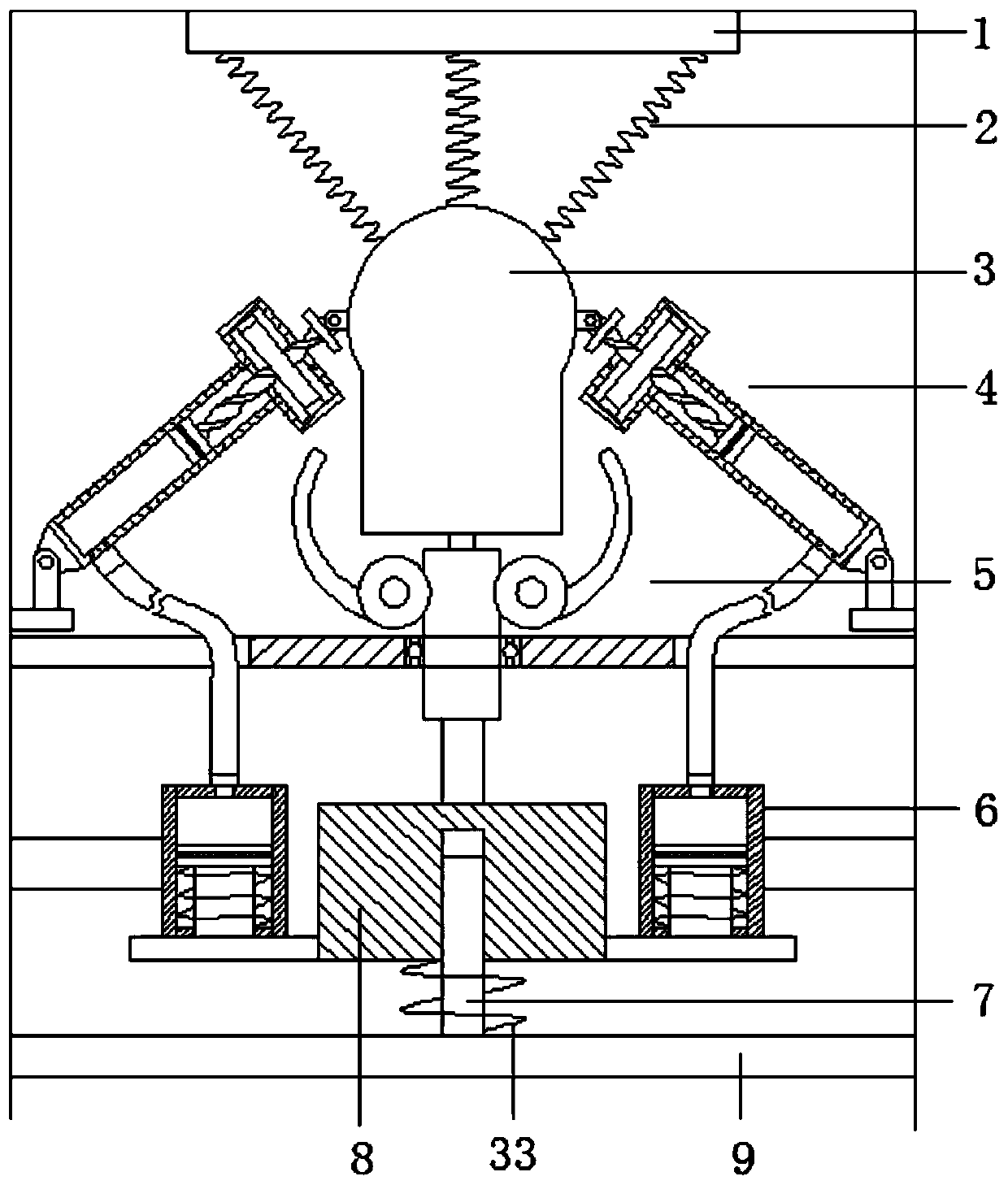

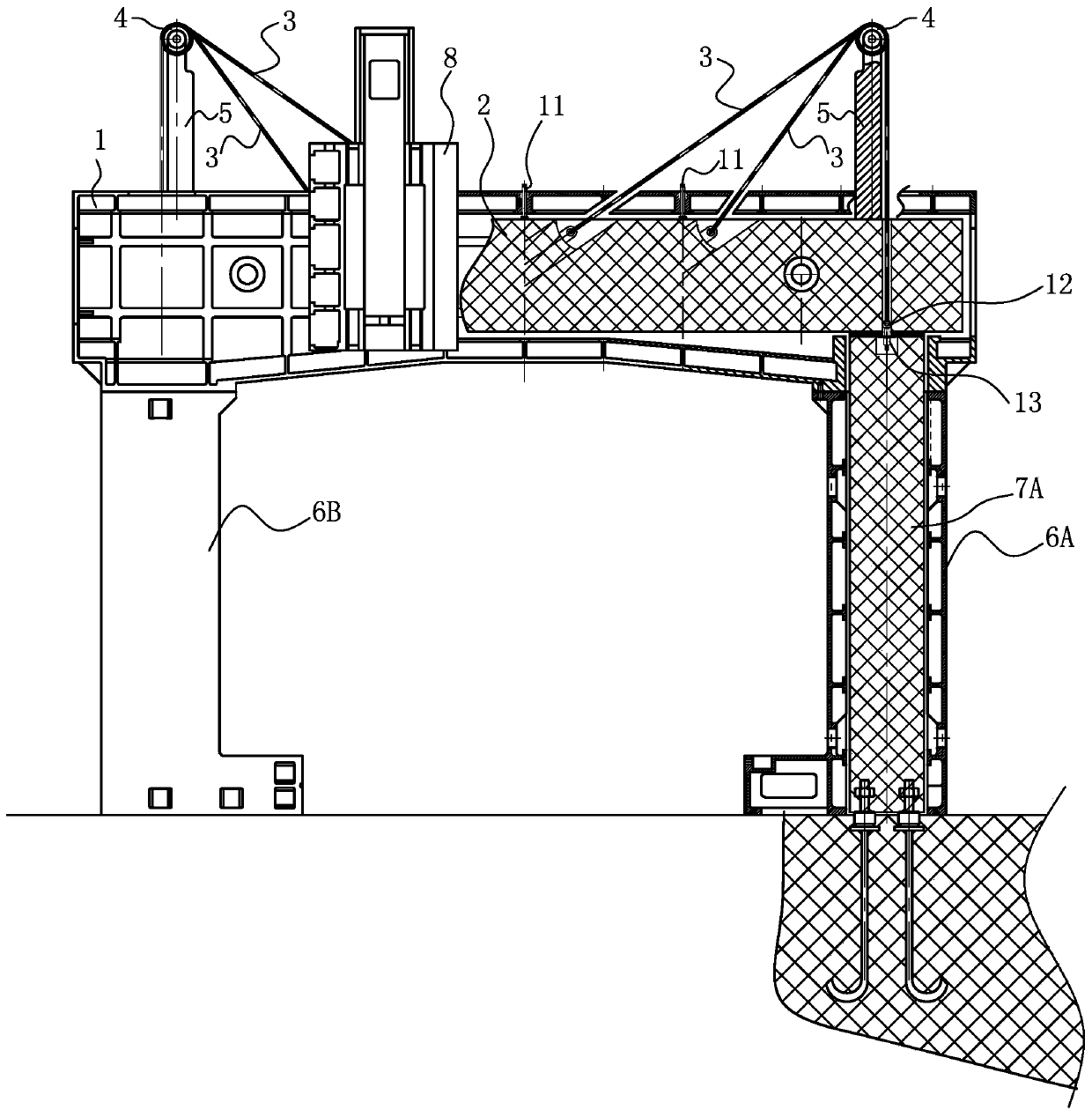

Vibration eliminating device applicable for building structure, and using method thereof

ActiveCN110644639APlay a shock absorbing roleAutomatic loss adjustmentProtective buildings/sheltersShock proofingArchitectural engineeringStructural engineering

The invention relates to the field of structure vibration reduction, in particular to a vibration eliminating device applicable for a building structure, and a using method thereof. The vibration eliminating device comprises a hanger plate, a baseplate and a mass block, and the hanger plate is fixed to the top of the building structure, and connected with the mass block through springs I; the baseplate is fixed to the building structure, and a plurality of damping mechanisms I are hinged to the side wall of the mass block; the lower ends of the damping mechanisms are hinged to the building structure, and each damping mechanism is connected with a damping mechanism II through a hydraulic pipe; the damping mechanisms II are fixed to the building structure, and the baseplate is provided witha counterweight block connected with the mass block through a return mechanism; and counterweight block can be connected with the damping mechanisms II. According to the vibration eliminating device applicable for the building structure, and the using method thereof, the energy consumption can be regulated according to the vibration degree in a self-adaptive mode, and the mass block can be promoted to return as soon as possible, so that the anti-vibration performance of the building structure is improved; and the service life of the building structure is prolonged, and the safety of the building structure is improved.

Owner:胡鸿韬

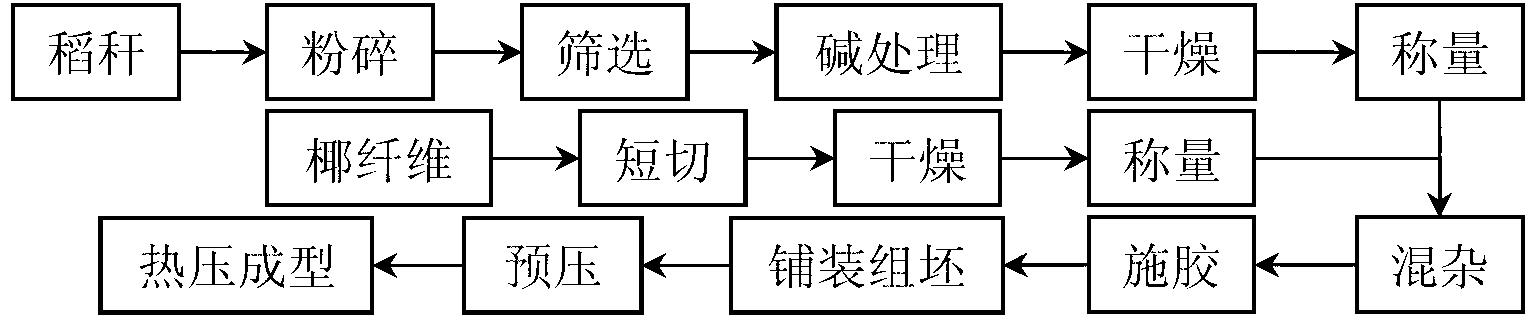

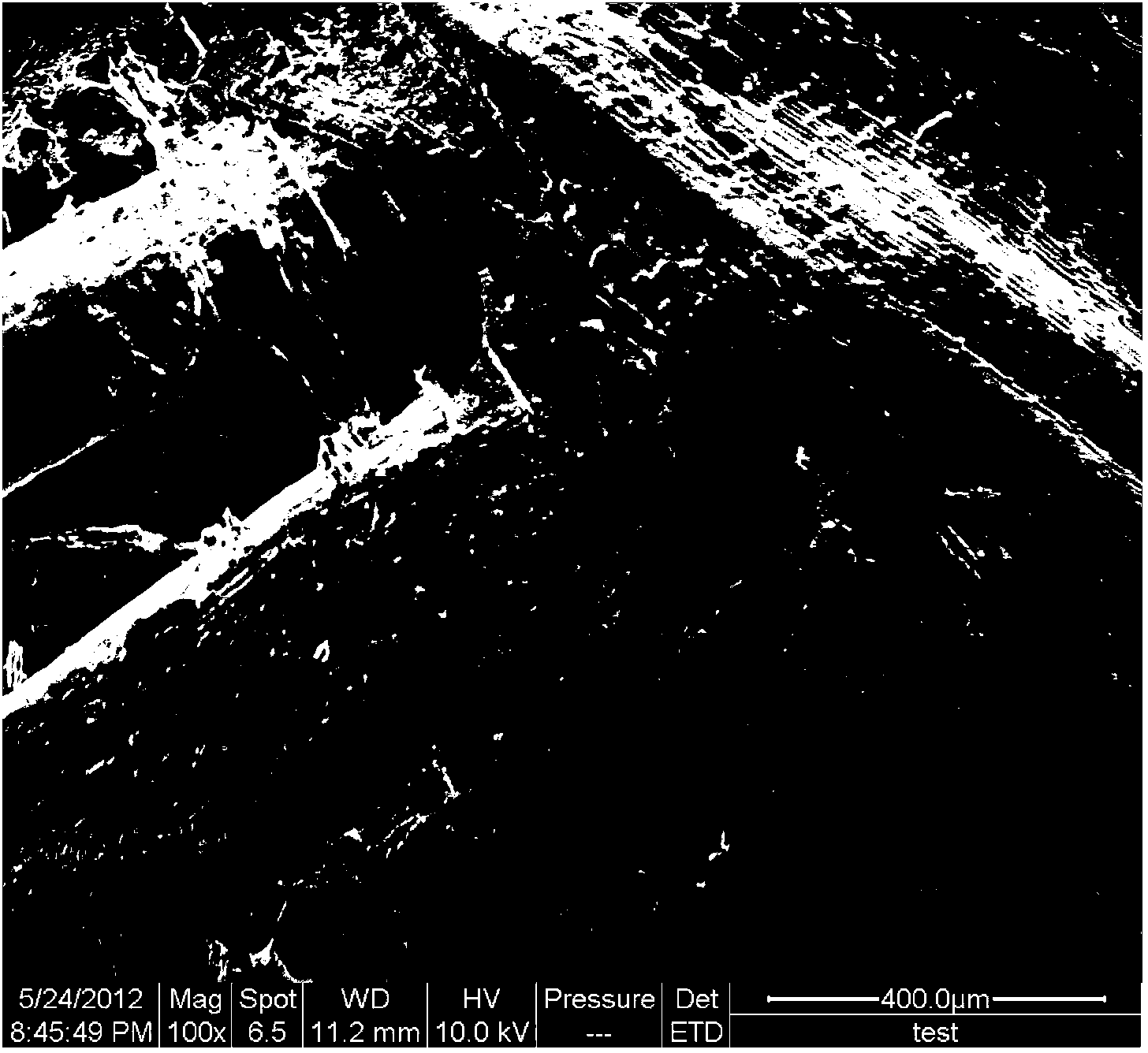

Coconut-fiber-reinforced crop straw composite material and manufacture method thereof

InactiveCN103072174ASimple preparation processImprove mechanical propertiesWood working apparatusFlat articlesAdhesiveToughness

The invention discloses a coconut-fiber-reinforced crop straw composite material and a manufacture method thereof, aiming to provide the strong-toughness and environment-friendly biomass composite material having good mechanical property, gluing property, toughness and vibration damping property. The coconut-fiber-reinforced crop straw composite material is formed by adding coconut fibers in crop straw units and uniformly dispersing as well as crossing and interconnecting the coconut fibers in a composite material system to form a bulky mesh structure, wherein the mass fraction of the coconut fibers in the system is 10-50%. The manufacture method comprises the following steps of: preparing and preprocessing of the straw units, preparing of the coconut fibers, unit mixing, gluing, paving and billet assembling, prepressing, hot-press or cold-press molding, postprocessing and the like. The coconut-fiber-reinforced crop straw composite material is free from isocyanate adhesives, so that the preparation cost of an artificial board can be reduced; and the coconut-fiber-reinforced crop straw composite material can be used as a structure material and a damping material and applied to bearing structures and in rigid use environments with frequent vibration fatigue actions and easily occurring impulse loads so as to play roles of bearing, supporting, damping and denoising, and thus, the application field of the crop straw artificial board is enlarged.

Owner:NORTHEAST FORESTRY UNIVERSITY

Damper with two-way throttle valves and air spring

InactiveCN103821868AImprove vibration damping performanceReduce energy consumptionSpringsGas and liquid based dampersAutomatic controlAir spring

The invention discloses a damper with two-way throttle valves and an air spring. The air spring is arranged outside a dual-cylinder oil gas damper to form a composite damping structure; the dual-cylinder oil gas damper uses a piston with multiple two-way throttle valve structures on the basis of the traditional damper. The traditional dual-cylinder hydraulic damper is improved, and the throttle valves are additionally arranged on the work piston so as to realize the automatic control on the liquid flow; the dual-cylinder oil gas damper and the external air spring can synchronously bear a load by adjusting the rigidity of throttle valve springs, so the composite damping device with the true meaning is formed; the graded damping effect of the bag-type air spring with three air bags is achieved by adjusting the initial air pressure and the size of the air bags and the integral damping performance of the damper is improved; the energy loss of the damper is reduced by setting the throttle valves under the condition that the damping performance is not affected.

Owner:JILIN UNIV

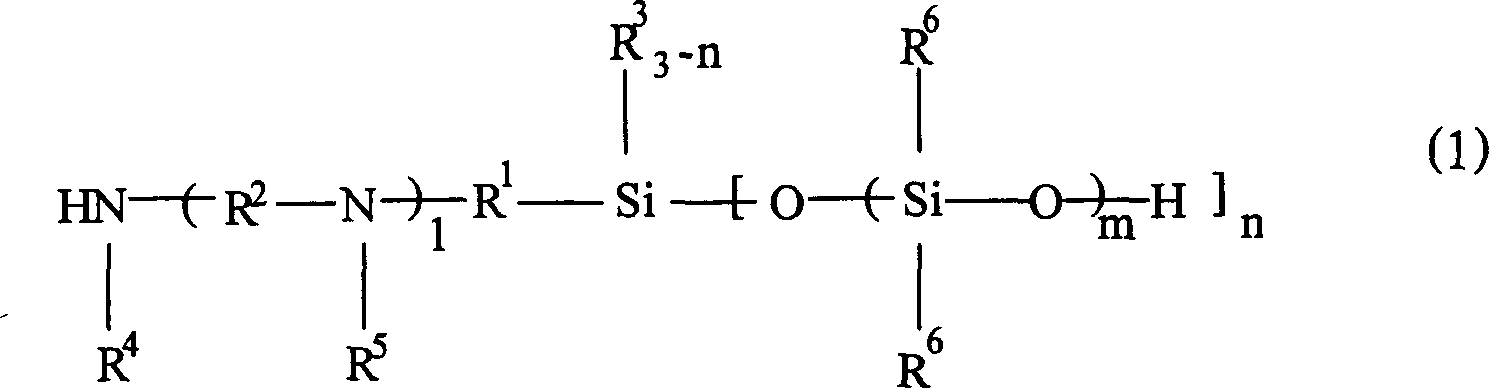

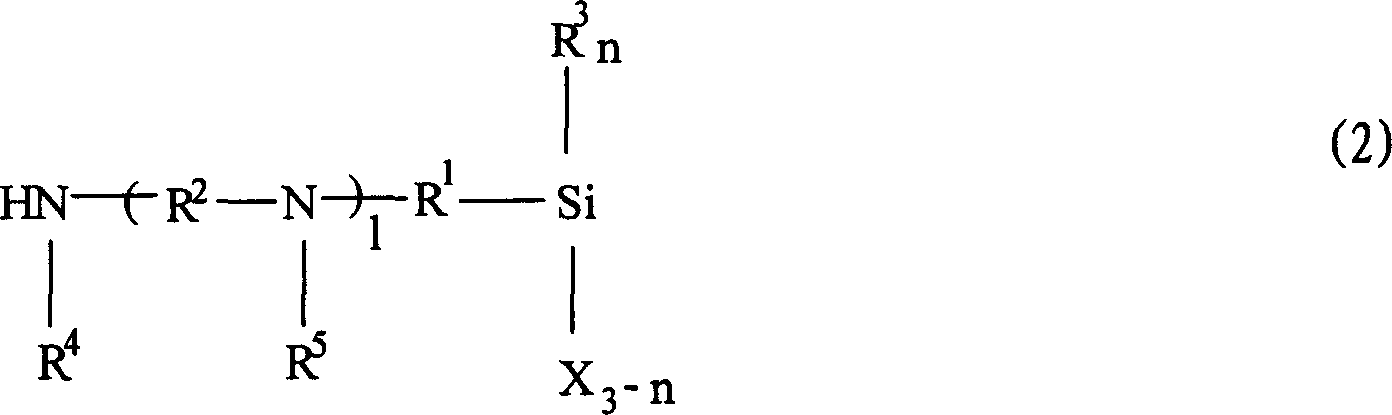

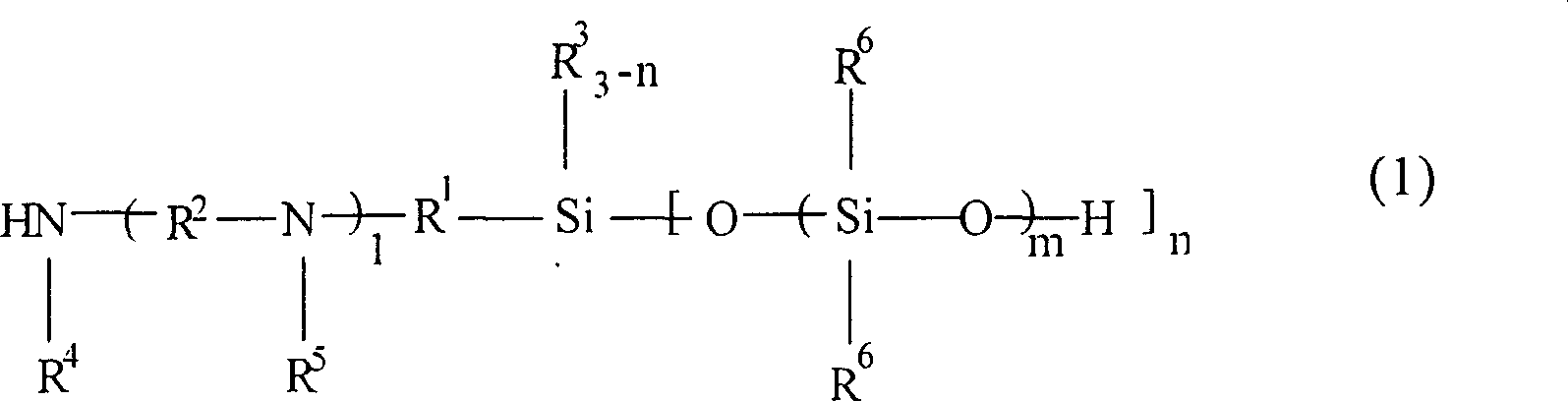

Silicone get composition

InactiveCN1418230AImprove damping effectGood shape retentionOther chemical processesNon-rotating vibration suppressionSilicone resinSilorane Resins

The invention provides a vibration-absorbing silicone gel composition mainly comprising: 100 parts by weight of (a) an organopolysiloxane having a (meth)acryloyl group in its molecule; from 5 to 100 parts by weight of (b) an organopolysiloxane unreactive with ingredient (a); from 1 to 50 parts by weight of (c) an amorphous pulverization product of a three-dimensionally crosslinked silicone resin; from 1 to 20 parts by weight of (d) a fumed silica; and an effective amount of (e) a polymerization initiator, as a gel composition which has high vibration-absorbing properties and high shape retention and which can be used as, e.g., a vibration-absorbing damper even when it is not sealed up in a container or bag.

Owner:THREEBOND FINE CHEM CO LTD

Noise damping thermoplastic composition

The present invention discloses a thermoplastic composition with characteristics of excellent vibration damping and noise inhibition, and a molding product prepared from the thermoplastic composition in a low cost manner. The noise damping thermoplastic composition contains (a) 75-98.9 wt% of fiber reinforcement agent-containing polyamide,; (b) 0.5-10 wt% of an impact modifier, (c) 0.5-5 wt% of nanometer clay, (d) 0.1-10 wt% of polyolefin, and (e) 0-15 wt% of other additives, wherein the component (d) polyolefin is not polyethylene.

Owner:EI DU PONT DE NEMOURS & CO

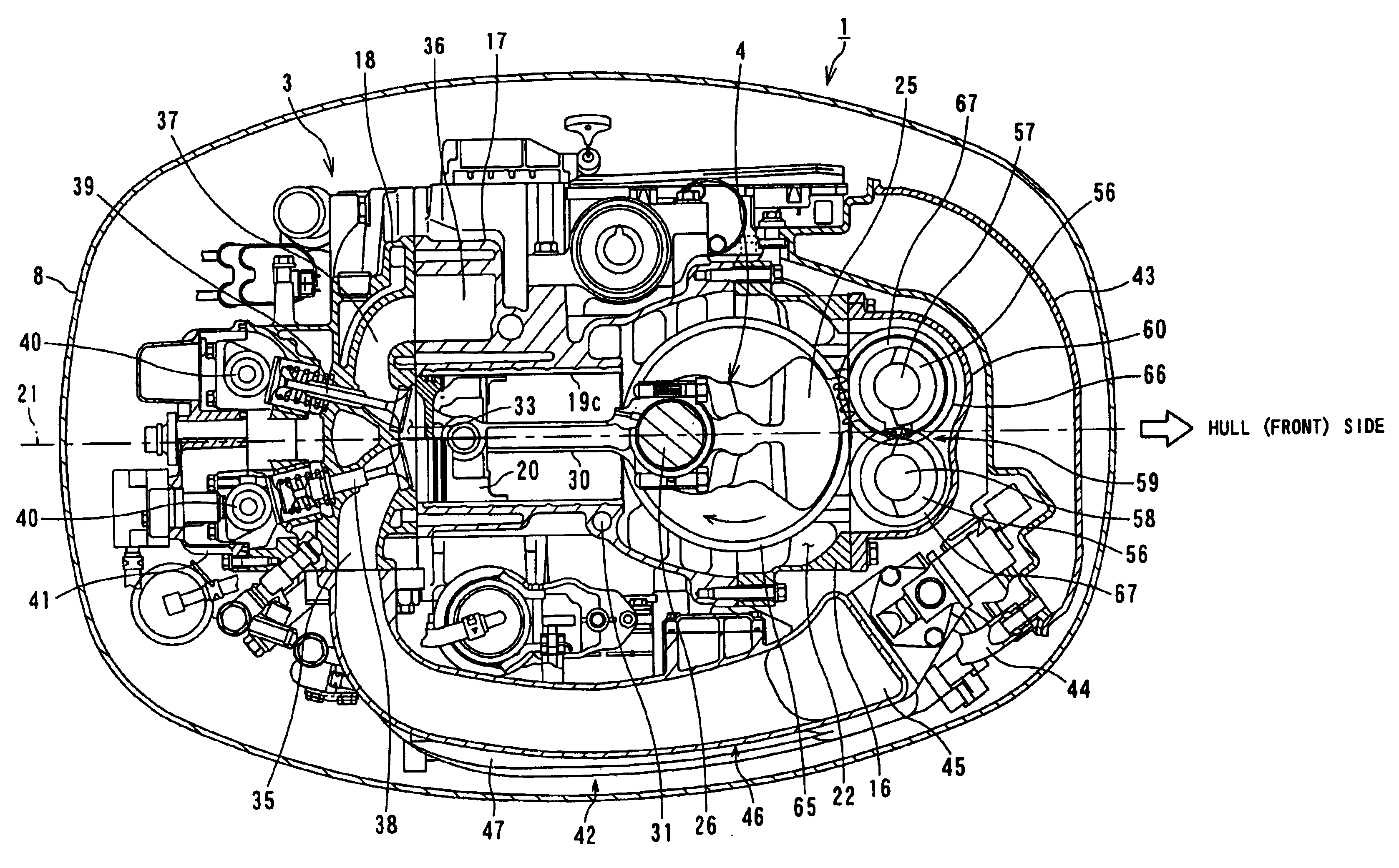

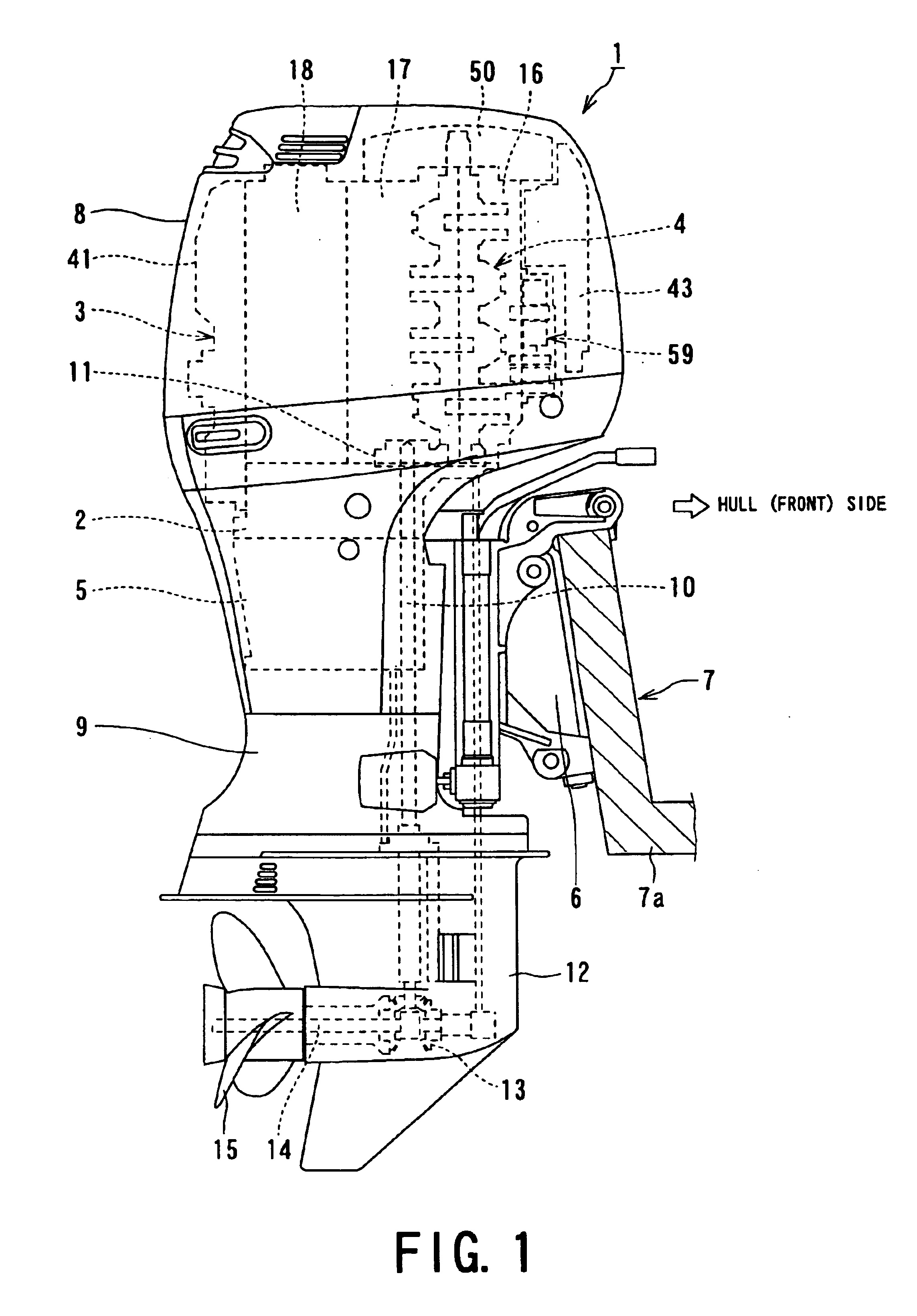

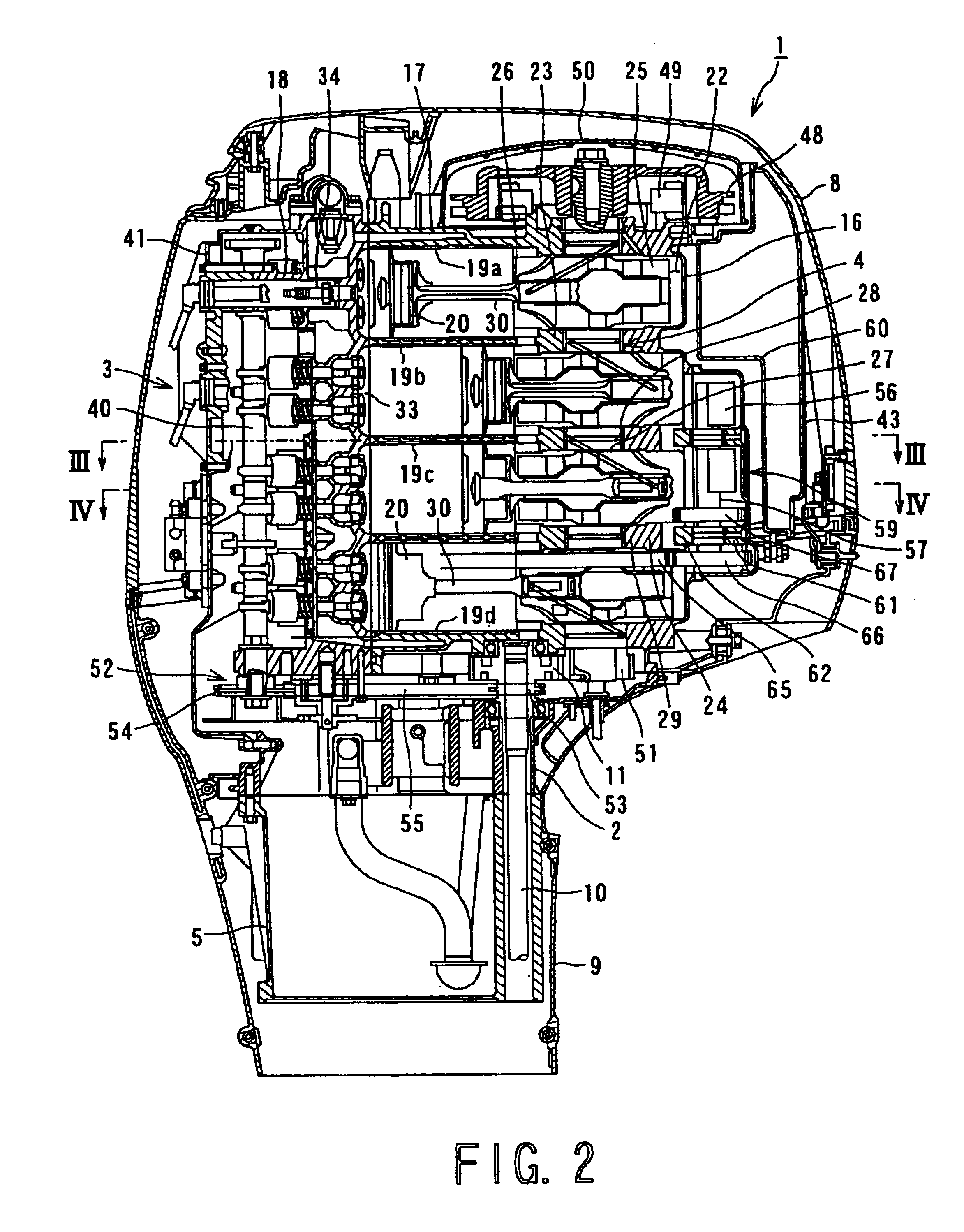

Secondary balancer of vertical engine of outboard motor

ActiveUS6848411B2Convenience to workEliminate needInertia force compensationPropulsion power plantsCylinder headCrankcase

A secondary balancer is used for an outboard motor vertical in-line engine which includes a crankcase, a cylinder block and a cylinder head, which are arranged in this order from a front side of the engine (i.e., hull side of an outboard motor), a crankshaft placed in the engine in a substantially vertical direction, an intake pipe placed on one side of the engine, a throttle body and an intake silencer which are disposed on a front side of the crankcase, and a balancing device including a primary balancer and a second balancer. The secondary balancer includes a pair of balancer shafts disposed in a space formed between the crankcase and the intake silencer.

Owner:SUZUKI MOTOR CORP

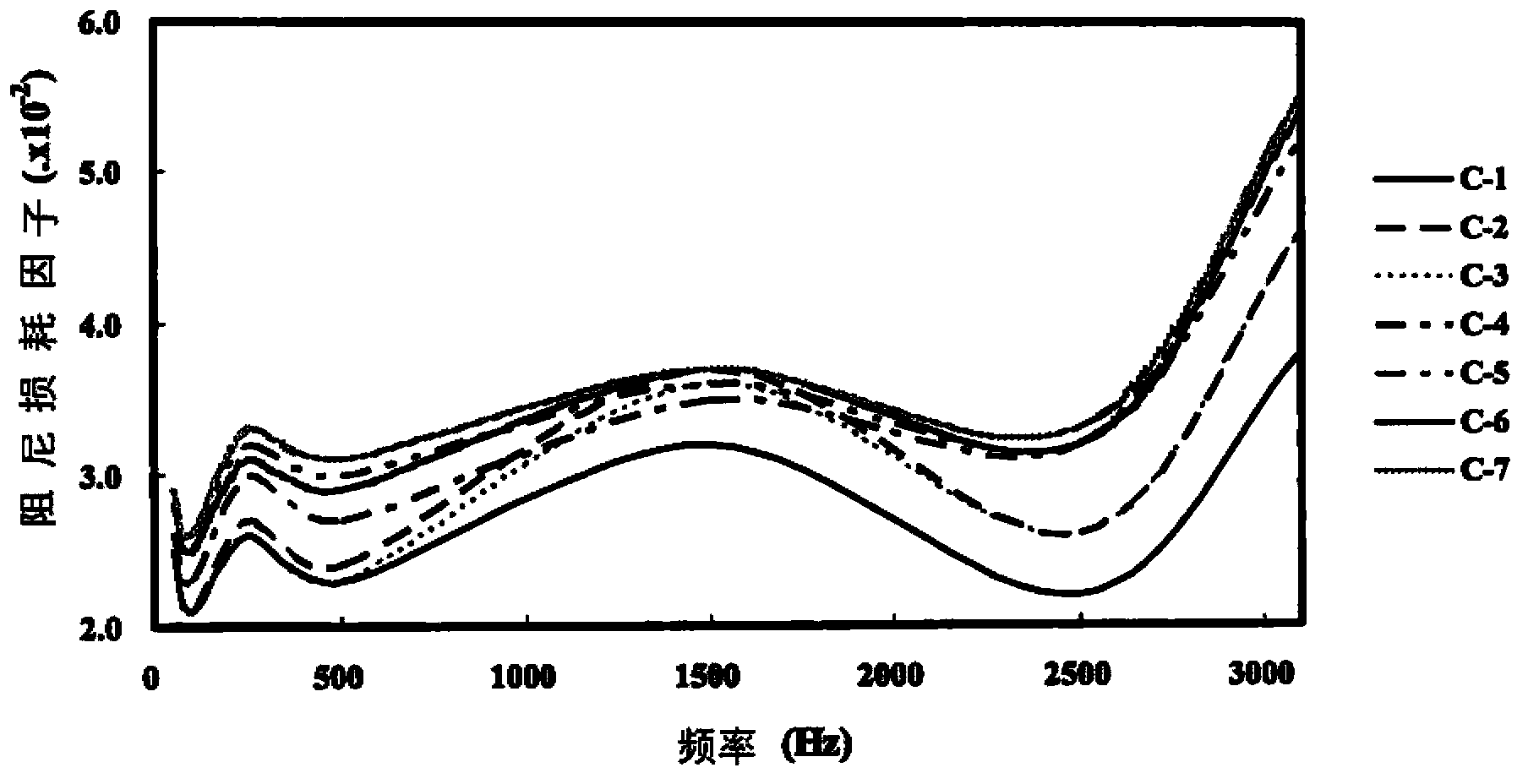

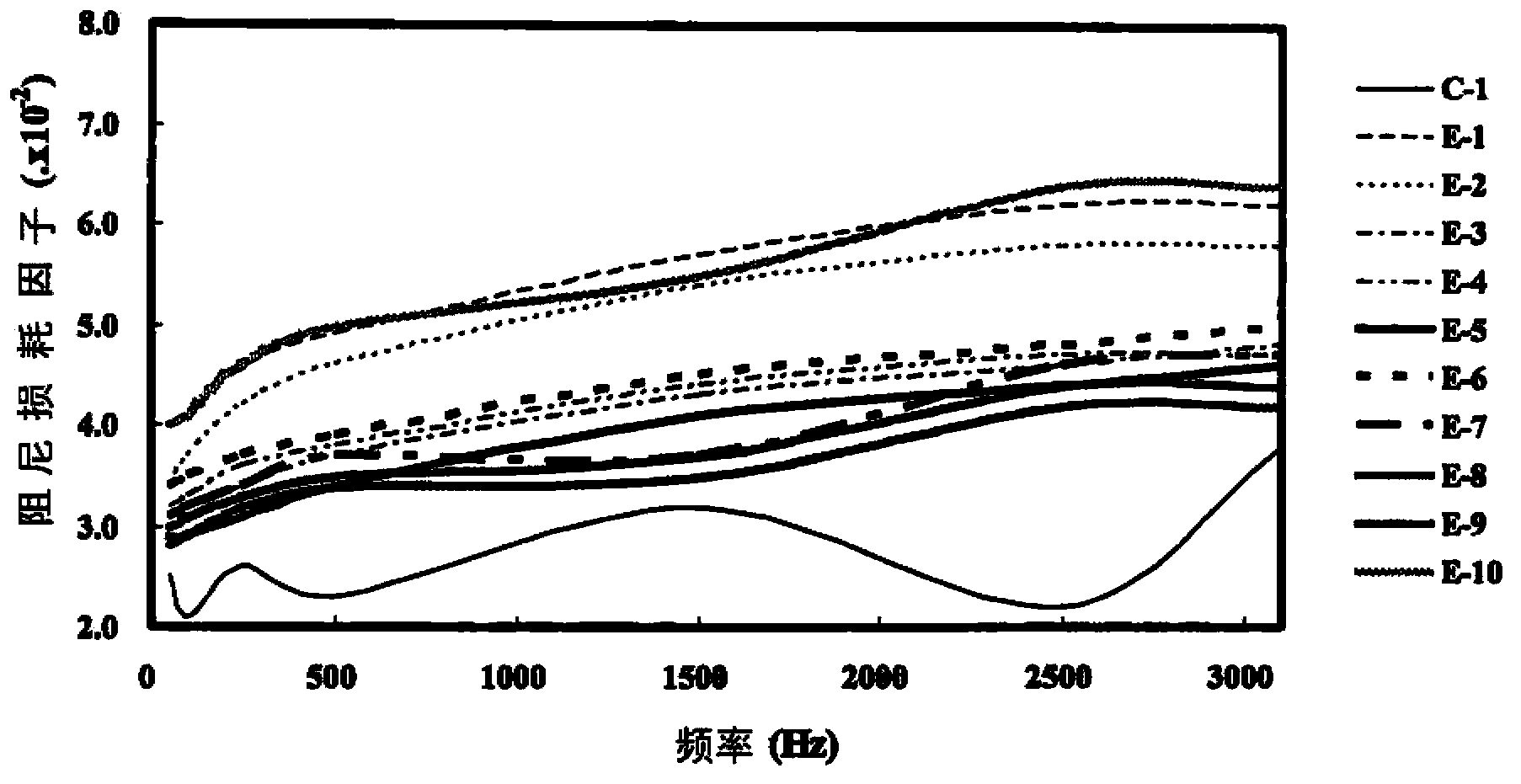

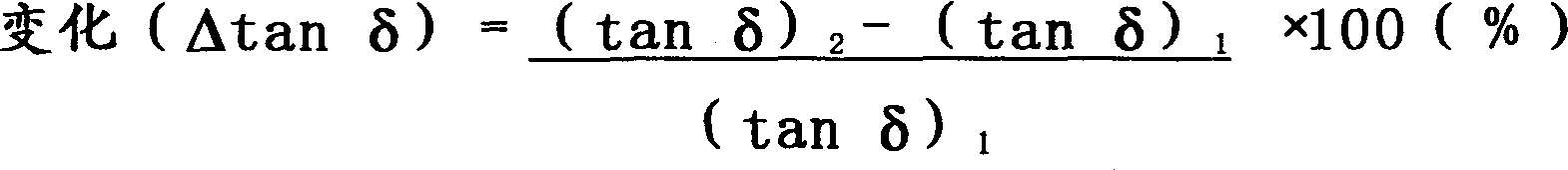

Vibration damping material composition

InactiveCN1488664AImprove vibration damping performanceIncreased durabilitySound producing devicesChemical compositionTan delta

It is an object of the present invention to provide a vibration damping composition having a high loss tangent (tan delta) and loss factor (eta), and serviceable over a wide temperature range. Provided is a vibration damping composition whose matrix material of organic polymer contains a vibration damping agent, and inorganic and / or organic filler, wherein the vibration damping agent is a phenol-based compound of limited steric hindrance which has a chemical composition free of a branched hydrocarbon group of 4 or more carbon atoms at each site adjacent to the hydroxyl group.

Owner:TYTEX AS

Heat preservation oscillation damping light concrete and preparation method thereof

InactiveCN108191323AEasy material selectionPreparation method scienceChemical reactionPotassium hydroxide

The invention discloses heat preservation oscillation damping light concrete. The concrete is prepared from, by weight, 110-140 parts of cement, 40-90 parts of coal ash, 10-30 parts of potassium hydroxide, 20-30 parts of mineral powder, 10-15 parts of polypropylene granules, 5-15 parts of cooked glutinous rice powder, 0.5-2 parts of thickener and 300-350 parts of water. The materials are selectedfinely, the preparation method is scientific, the coal ash and the potassium hydroxide are subjected to a chemical reaction under the steam curing condition, a compound with the water hardening gelling property is generated, the temperature of the concrete is increased, the heat preservation property of the concrete is improved, by adding the cooked glutinous rice powder, the raw materials of thelight concrete can be condensated, the oscillation damping effect is enhanced, tenacity can be improved due to polypropylene, and the concrete is high in bearing capacity, light in structure, low in cost and worthy of being popularized.

Owner:张宇涵

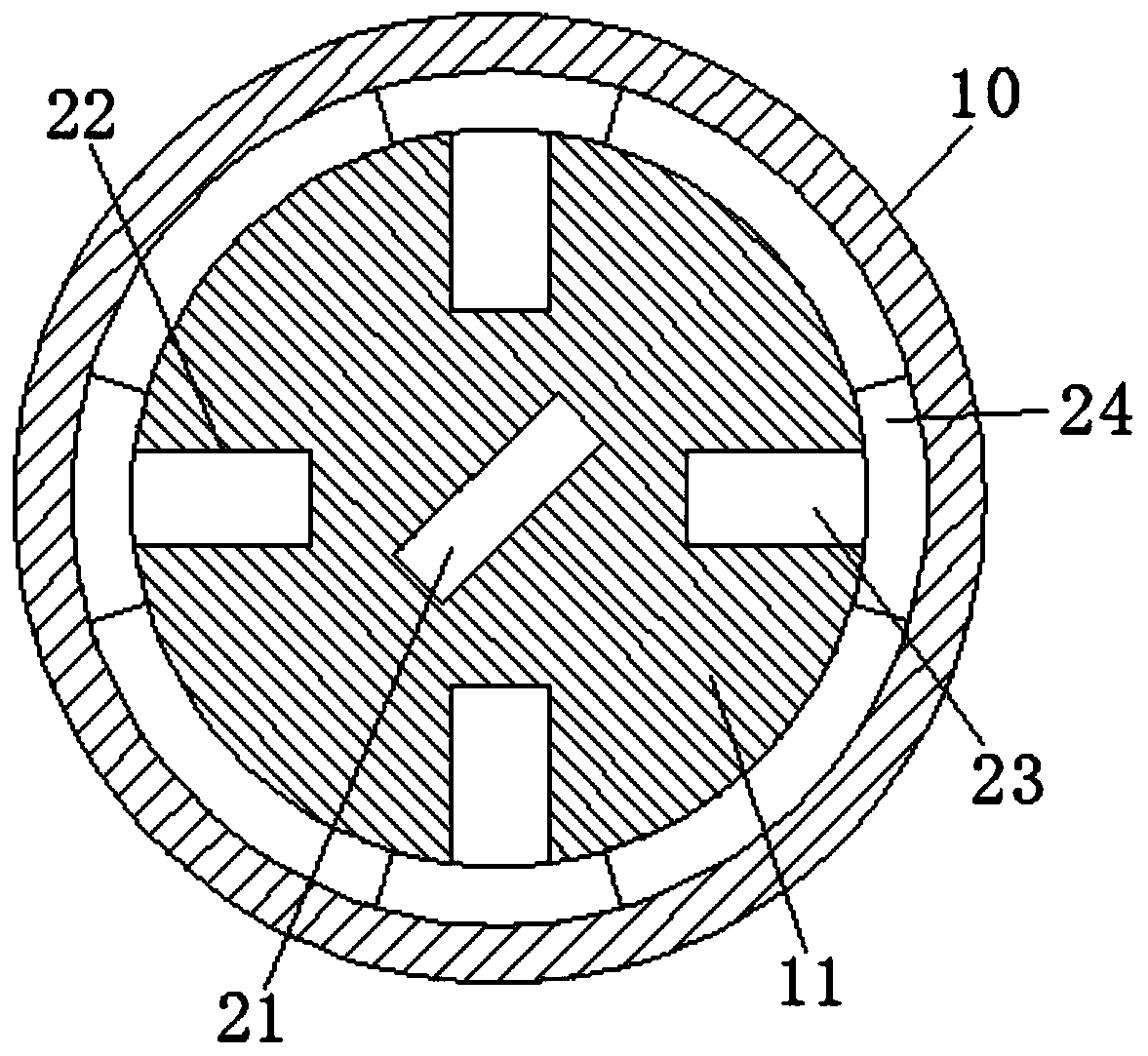

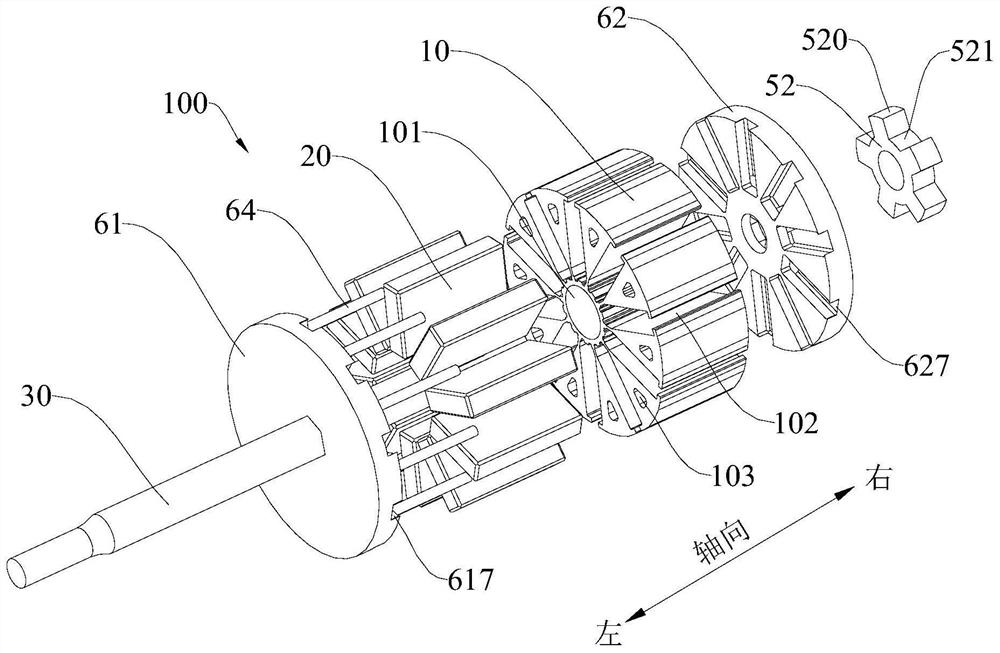

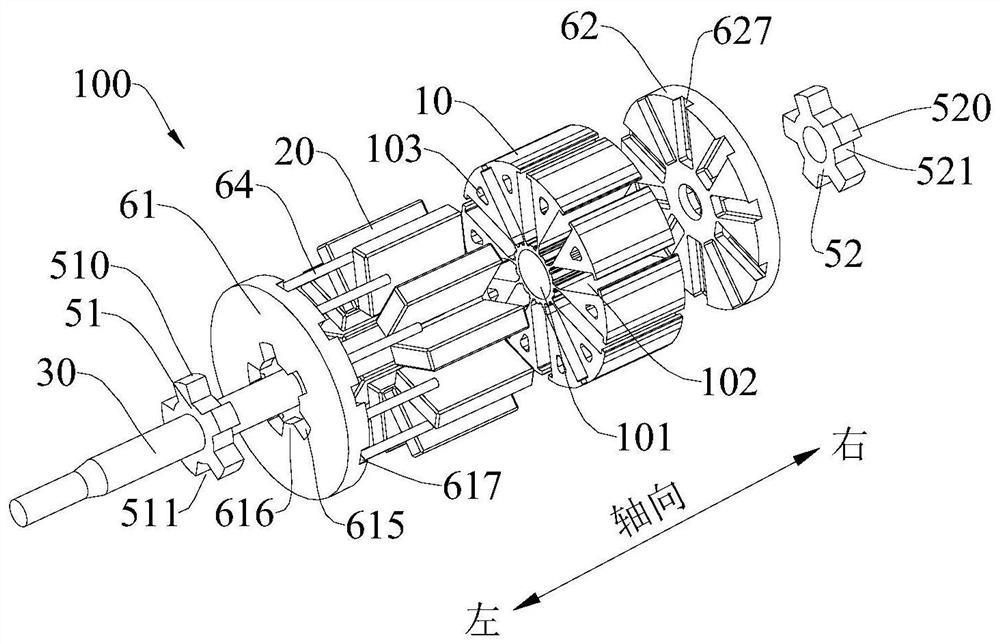

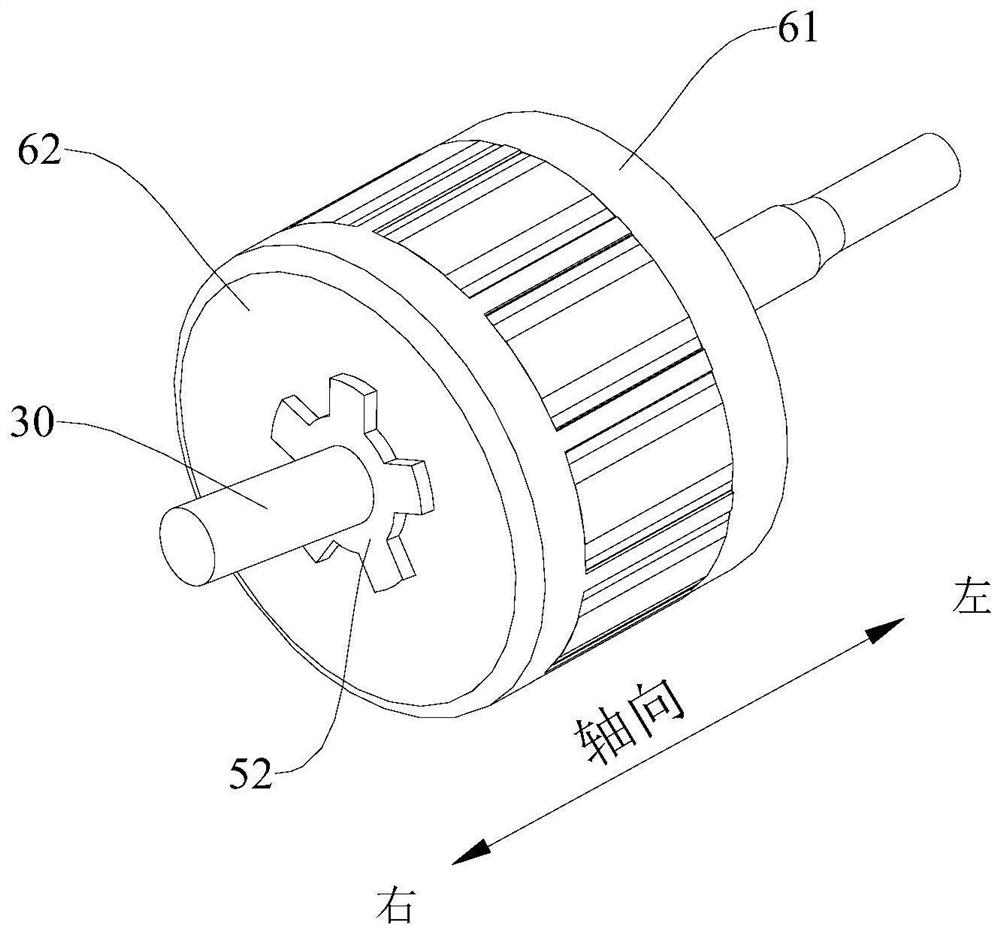

Vibration reduction rotor assembly and motor

PendingCN111769664AImprove vibration damping performanceReduce vibration and noiseMagnetic circuit rotating partsSupports/enclosures/casingsPhysicsElectric machinery

The invention discloses a vibration reduction rotor assembly and a motor. The vibration reduction rotor assembly comprises a rotor iron core, a permanent magnet, a rotating shaft and a first end vibration reduction piece. The rotor core is provided with magnet grooves and a rotating shaft hole. The permanent magnets are arranged in the magnet grooves. A rotating shaft is arranged in the rotating shaft hole. The first end and the second end of the rotating shaft extend out of the rotating shaft hole. A gap is formed between the rotating shaft and the rotor core. The first end part vibration reduction piece is arranged on the first end surface of the rotor iron core and is connected with the rotor iron core. On the axial direction of the rotor core, the first end of the permanent magnet extends out of the magnet groove and is matched in the first end vibration reduction piece or the first end of the permanent magnet retracts into the magnet groove so that one part of the first end vibration reduction piece can be matched in the magnet groove, and the first end vibration reduction piece is directly matched with the rotating shaft or matched with the rotating shaft through a first transmission piece arranged in the first end vibration reduction piece. According to the vibration reduction rotor assembly, the material amount of the vibration reduction part can be increased, the vibration reduction performance is good, and the vibration noise is low.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

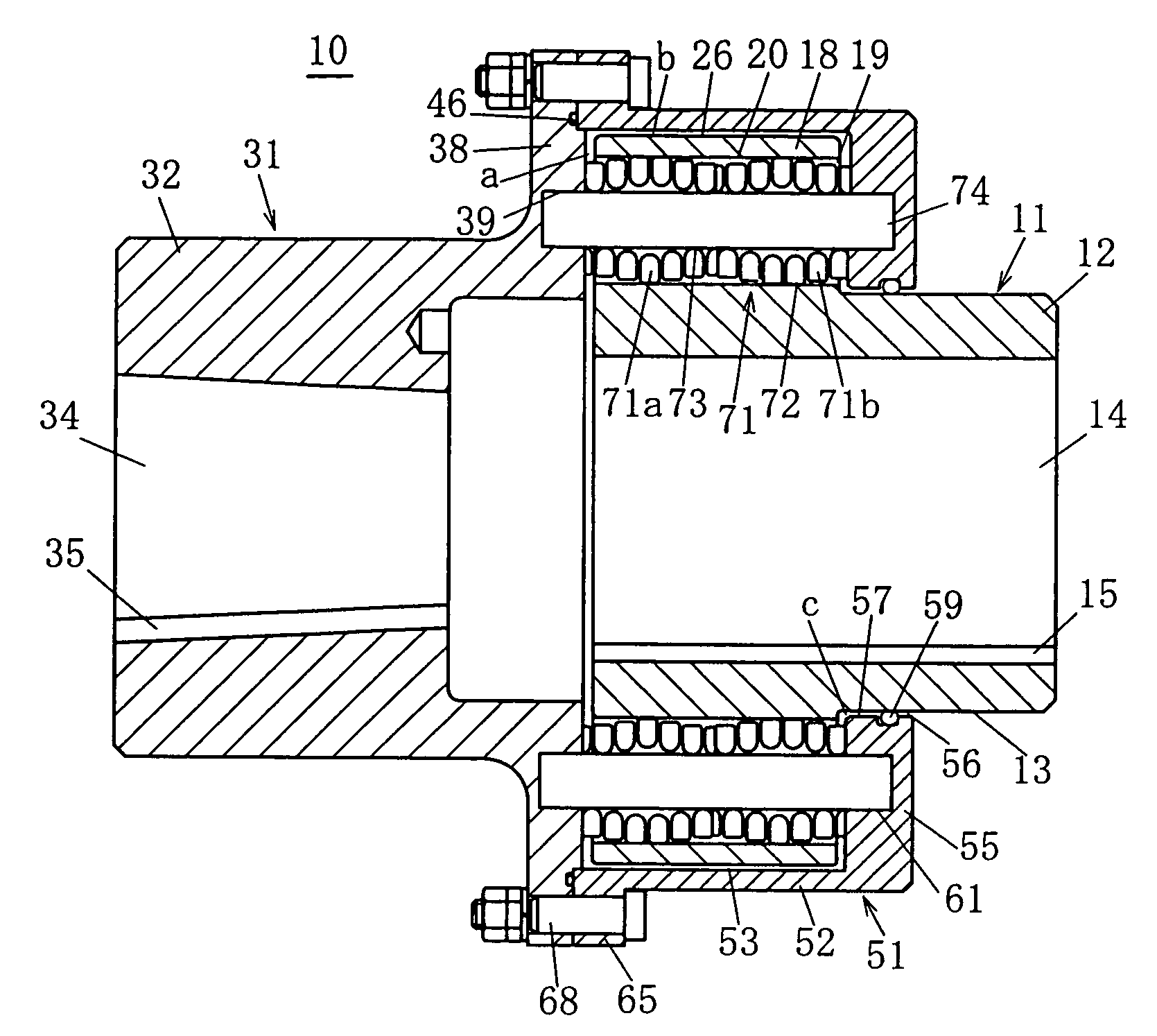

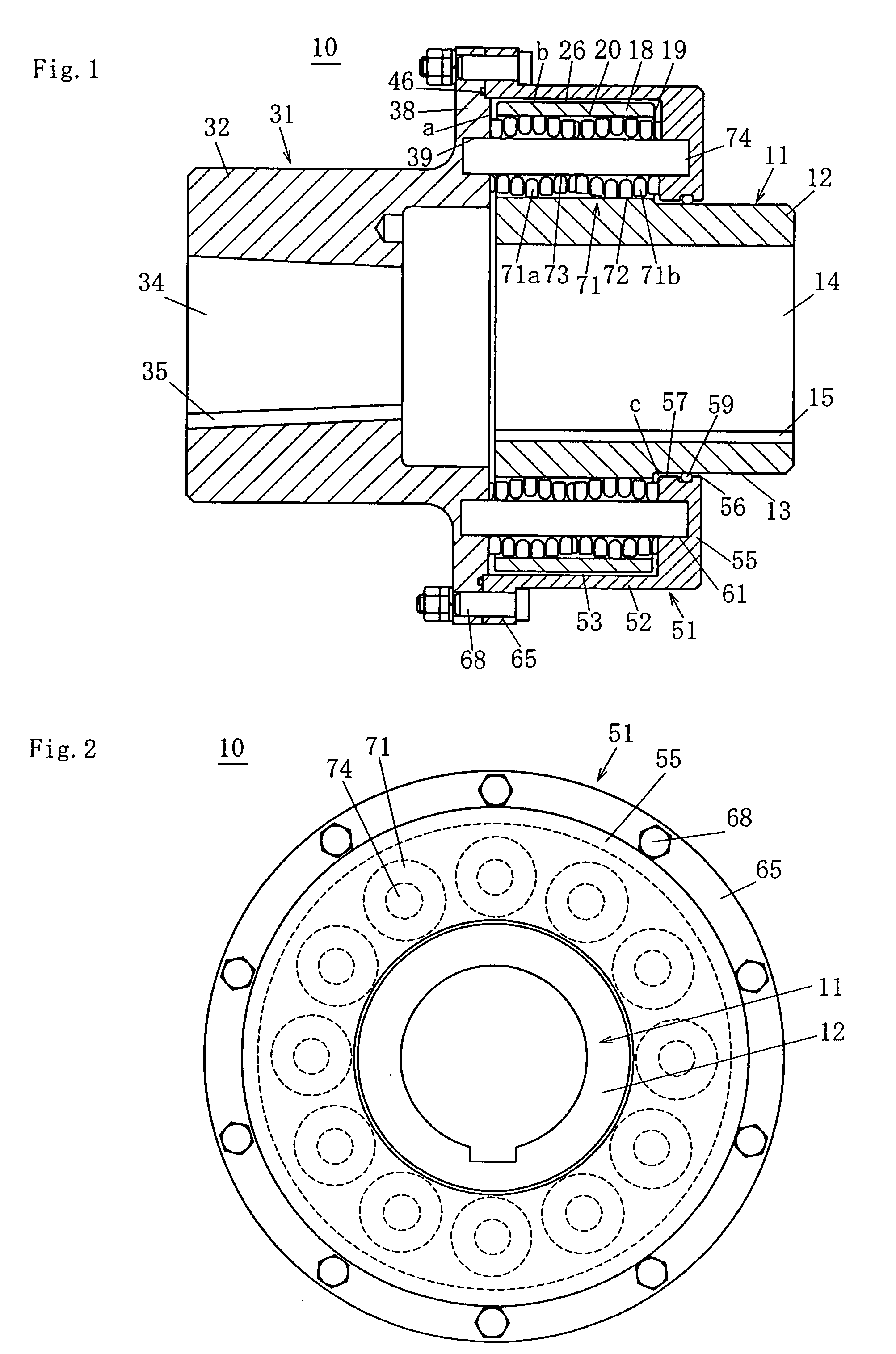

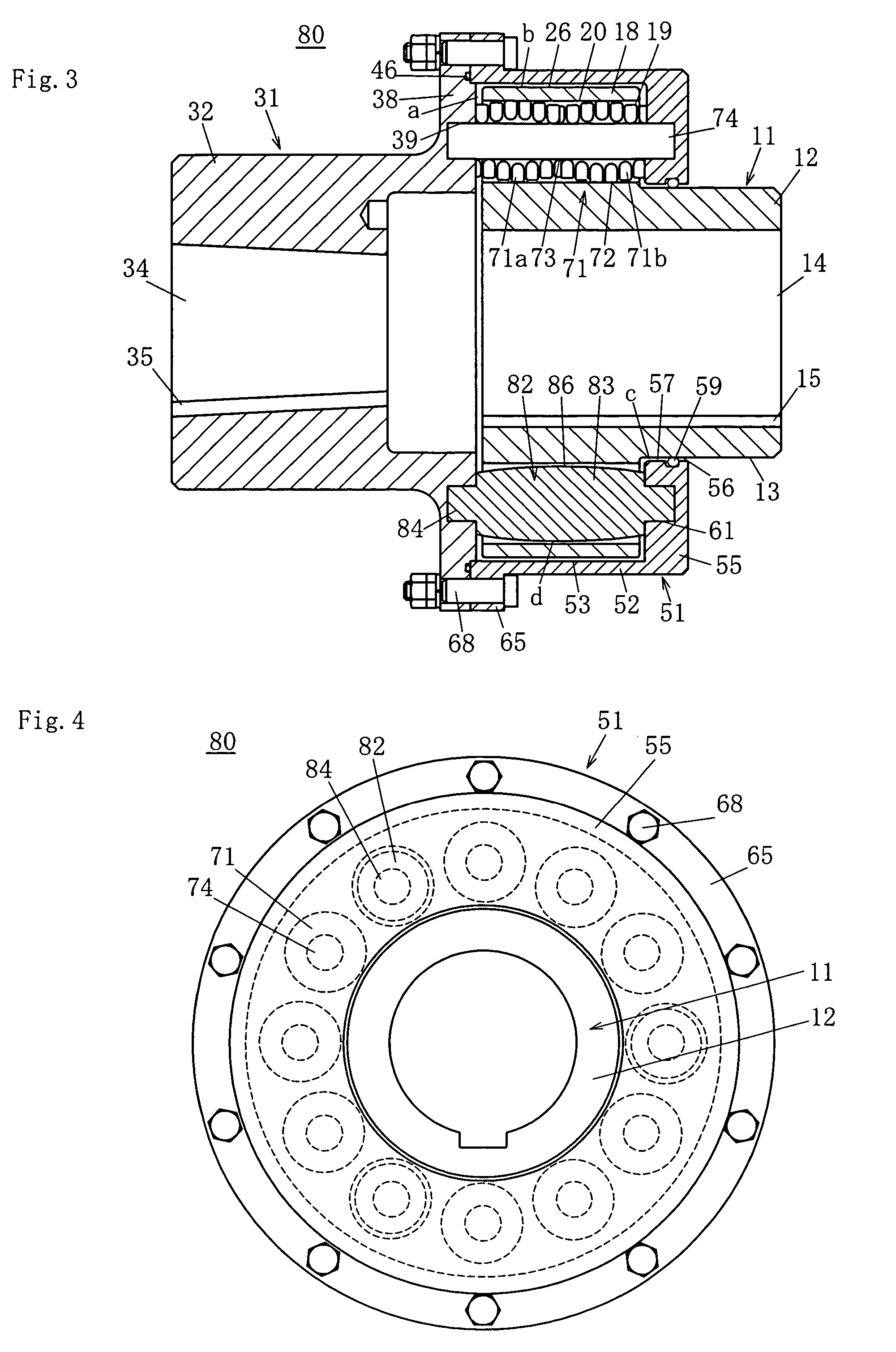

Flexible shaft coupling

ActiveUS20050221899A1Improve shock absorptionImprove vibration damping performanceYielding couplingLiving organism packagingCouplingDrive shaft

A flexible shaft coupling has first and second hubs, each of which is provided with flanges and connected to a transmission shaft. The flange of the first hub has spring holes extended therethrough. A cover fixed to the second hub so that the flange of the first hub is held between the cover and the flange of the second hub, and the cylindrical part of the first hub extends through the cover. A plurality of coil spring sets each comprises multiple barrel-shaped coil springs. Each of the coil springs is supported in the spring hole so that the adjoining end faces thereof are in contact and in series with each other.

Owner:KYUSHU HASEC +1

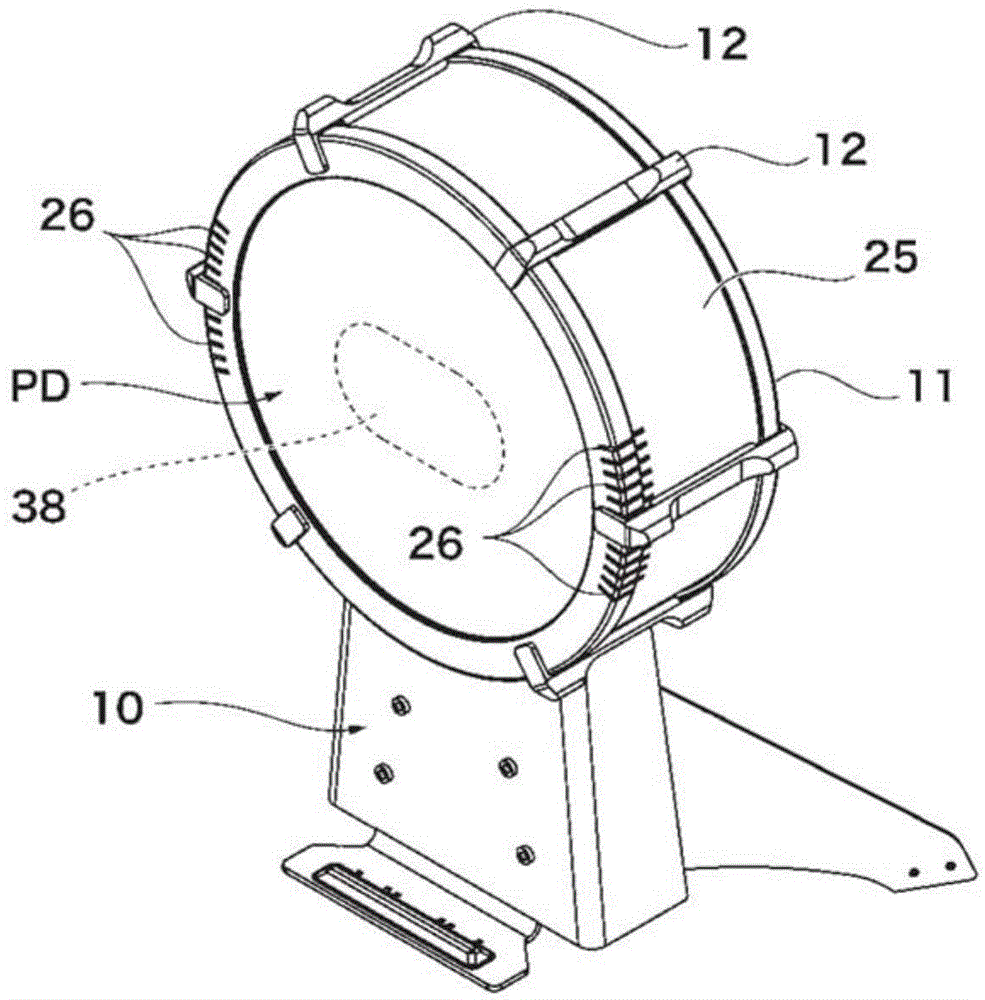

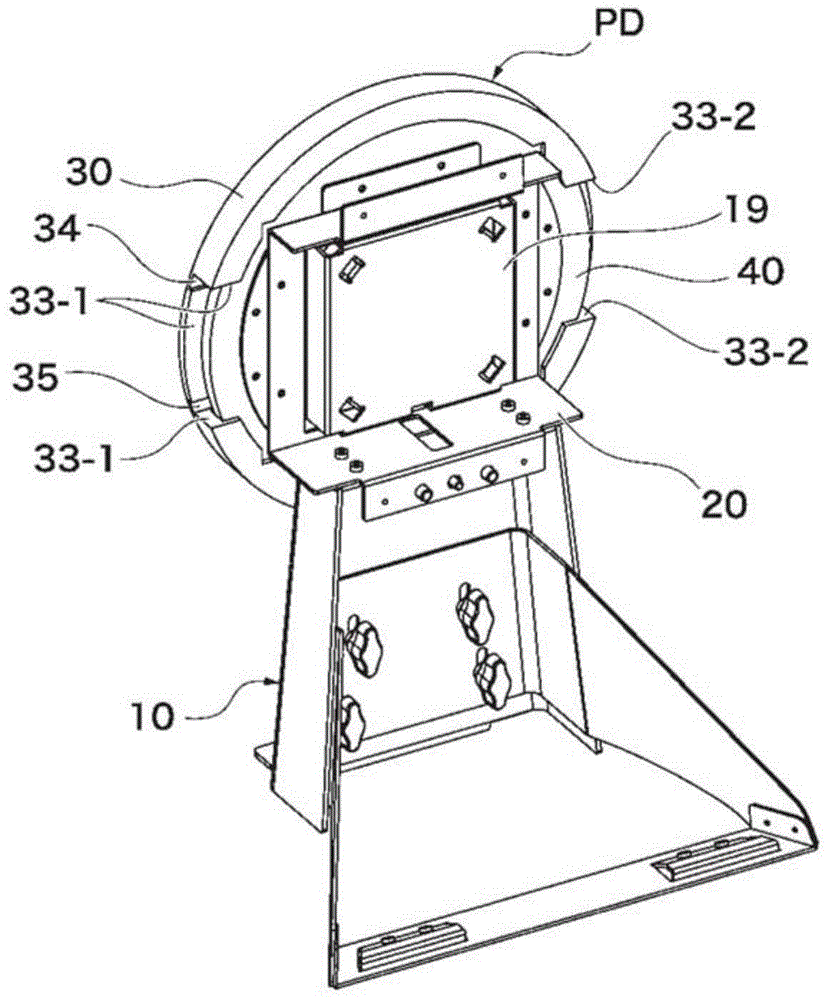

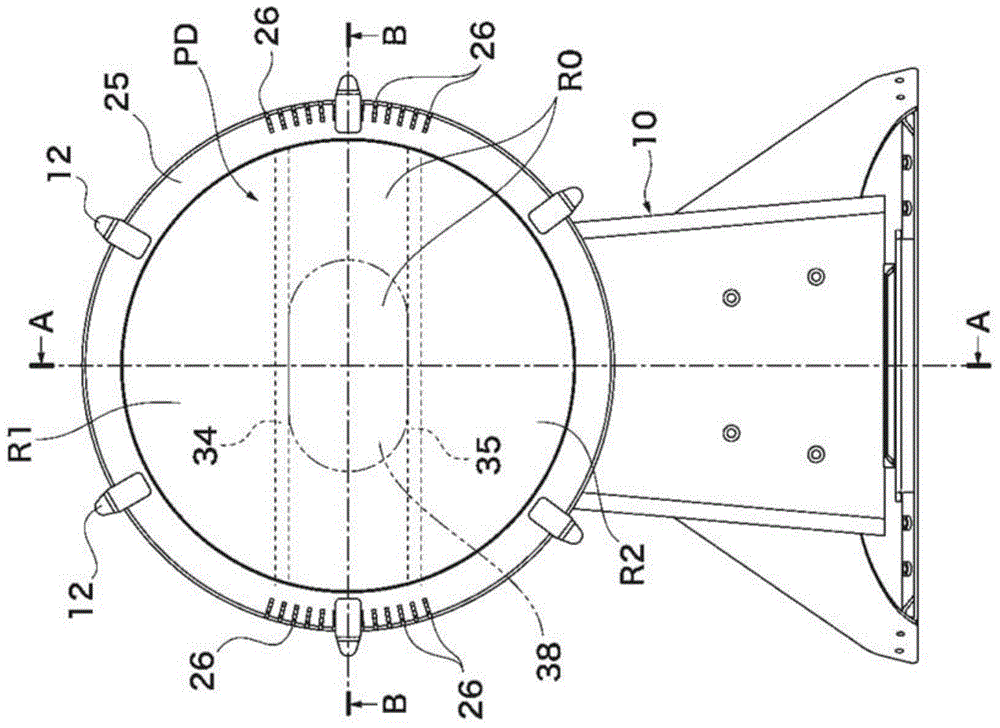

Electronic percussion instrument

ActiveCN104050956ADamping Vibration Damping EffectImprove vibration damping performanceElectrophonic musical instrumentsPercussion musical instrumentsEngineeringElectric signal

An electronic percussion instrument includes a head, a frame, and an impact sensor, and a plate serving as a vibration-damping member. The back of the head is divided into a main area (e.g. a main strike area) and an auxiliary area. The plate is ring-shaped sheet, made of a harder material (e.g. a metal) than the head, with an elongated hole and attached to the head to encompass or sandwich the main strike area of the head, thus demonstrating a vibration-damping effect. When the main strike area of the head is being struck with a beater, a vibration is caused to occur in the head and detected by the impact sensor to produce an electric signal which is used to generate an electronic musical sound while the vibration-damping member suppresses vibration being transmitted through the head due to an impact of the beater on the head.

Owner:YAMAHA CORP

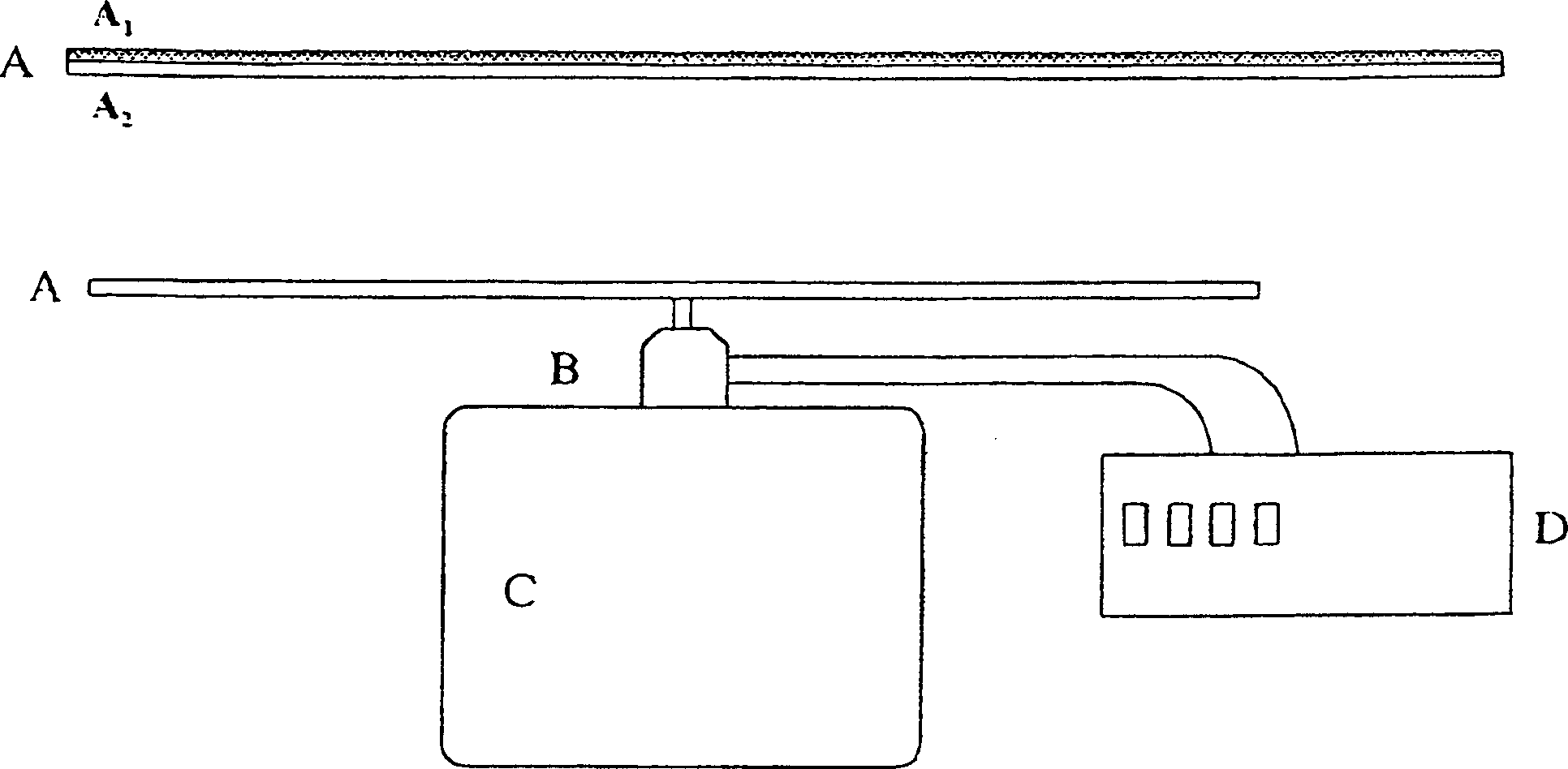

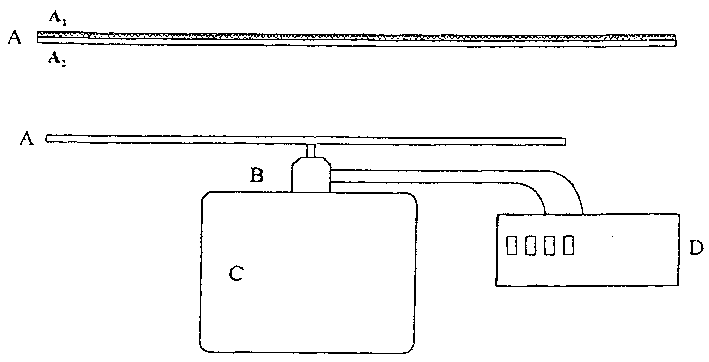

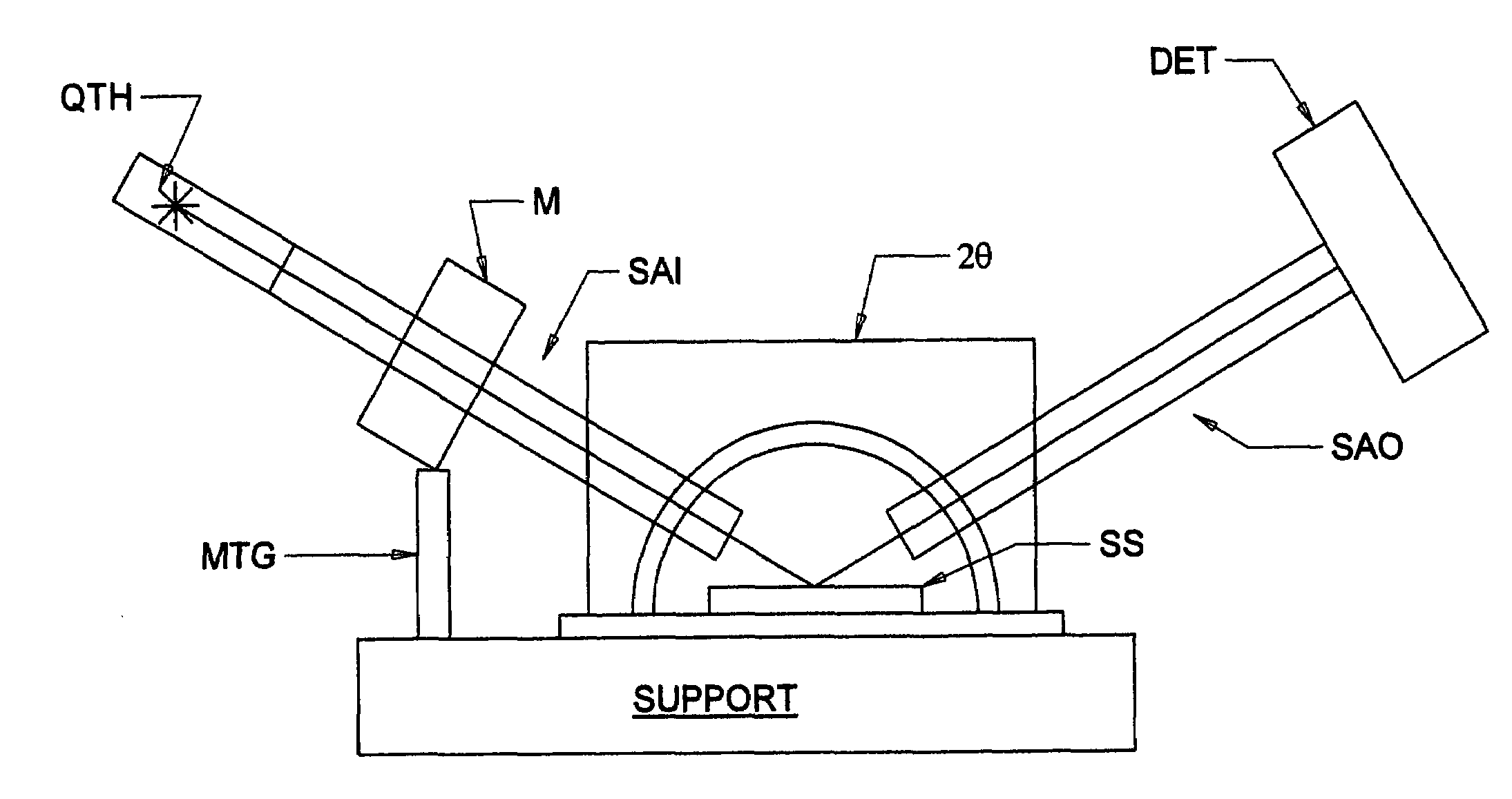

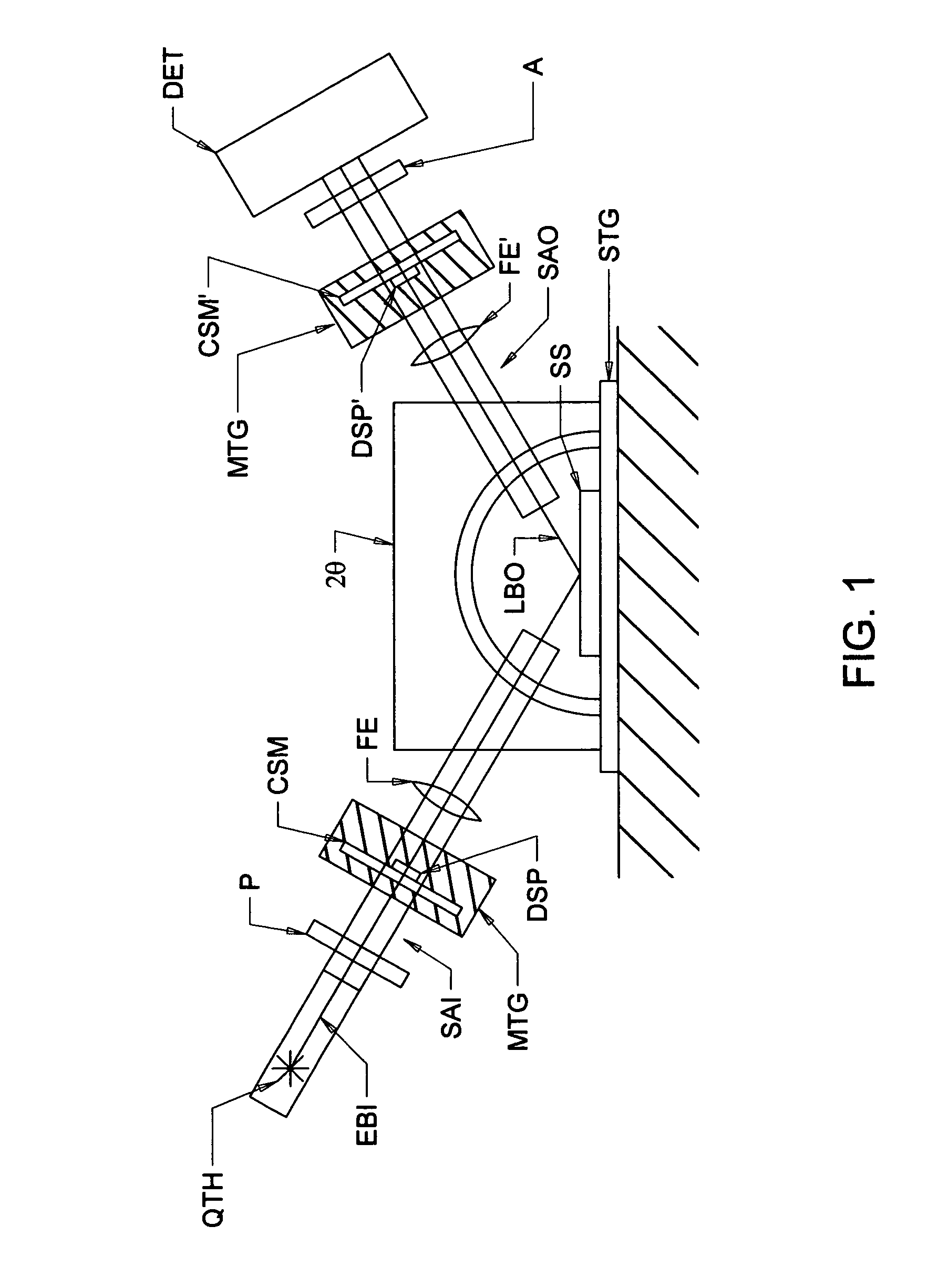

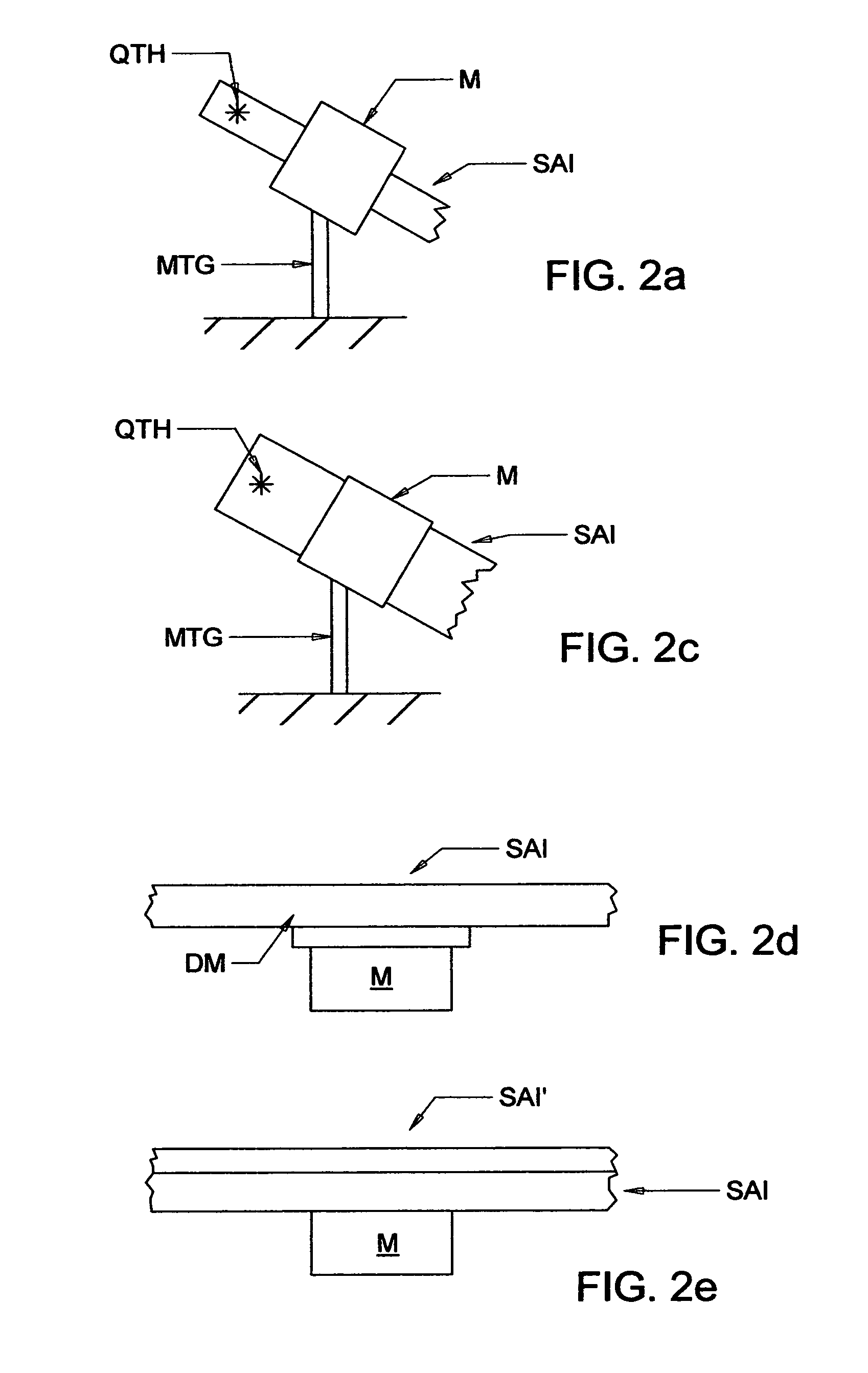

System for and method of reducing change caused by motor vibrations in ellipsometers, polarimeters or the like

ActiveUS7623238B1Slow changeImprove vibration damping performanceMaterial analysis by optical meansLight polarisation measurementMotor vibrationClassical mechanics

A system and method which reduces change in locus of a beam of electromagnetic radiation which otherwise result from vibrations caused by operation of a motor which controls the rotation of an element which affects the beam.

Owner:J A WOOLLAM CO

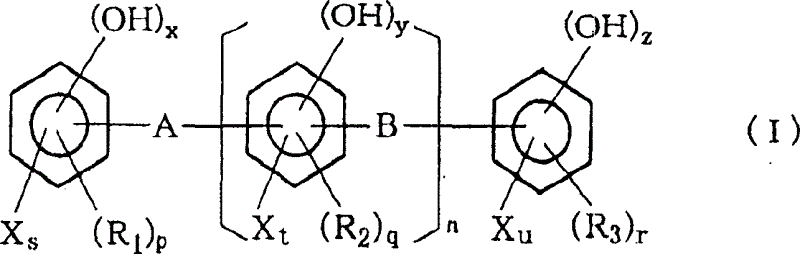

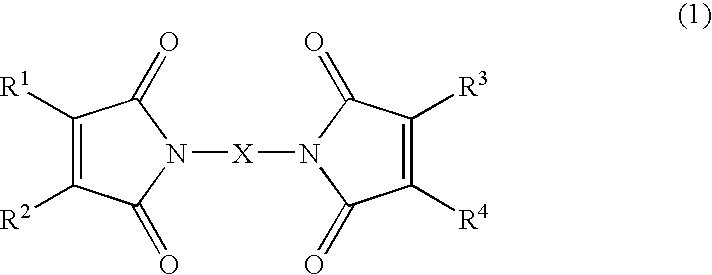

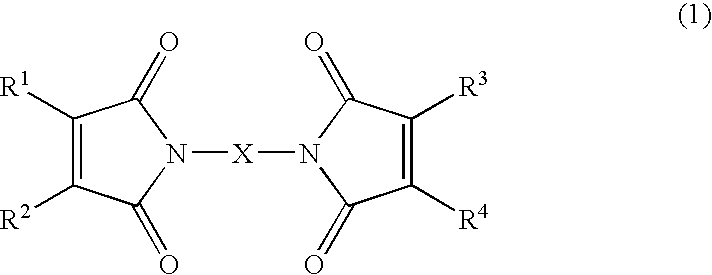

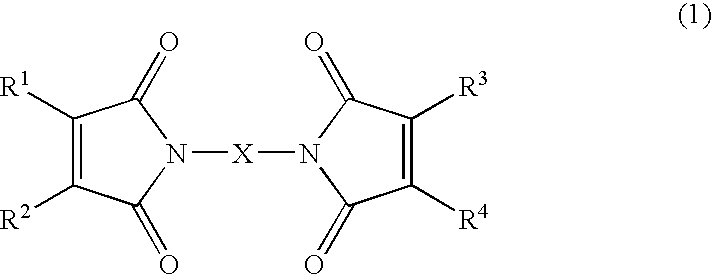

Vibration damping rubber composition

A vibration damping rubber composition having an excellent vibration damping performance includes the following (A) to (C) as essential components:(A) a diene-based rubber;(B) a vulcanizing agent of a bismaleimide compound represented by the following formula (1):[wherein X denotes a substituted or unsubstituted aliphatic saturated hydrocarbon group; and R1 to R4 may be the same or different and each denote a hydrogen atom, an alkyl group, —NH2, or —NO2, provided that the bismaleimide compound represented by formula (1) excludes a compound in which X is —(CH2)n- (n is an integer of 4 to 12) and all R1 to R4 are hydrogen atoms], wherein the vulcanizing agent is sulfur-free; and(C) a vulcanization accelerator.

Owner:SUMITOMO RIKO CO LTD

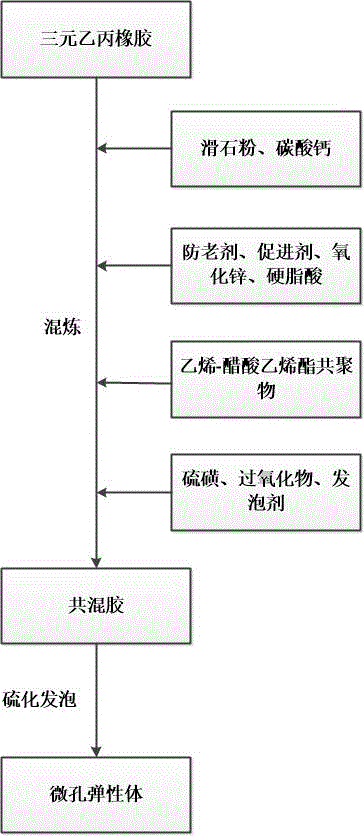

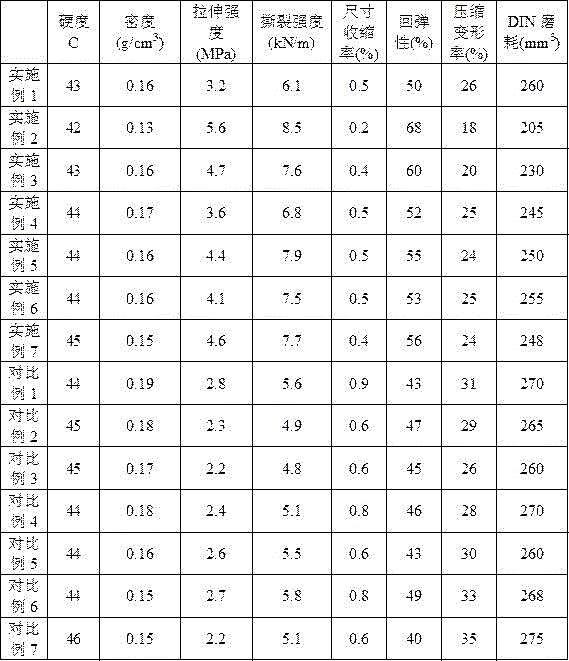

Microporous elastomer with high vibration reducing performance and preparation method thereof

ActiveCN106009316AImprove vibration damping performanceImprove mechanical propertiesChemistryStearic acid

The invention relates to a microporous elastomer with the high vibration reducing performance and a preparation method thereof. The microporous elastomer is mainly characterized by being prepared from, by mass, 55 parts of ethylene propylene diene monomer rubber, 45 parts of an ethylene-vinyl acetate copolymer, 10-15 parts of talcum powder, 5-10 parts of calcium carbonate, 2-5 parts of an anti-aging agent, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 0.5-1 part of an accelerant, 1-3 parts of sulphur, 0.5-1 part of peroxide and 3-8 parts of a foaming agent. The microporous elastomer prepared through the method has the advantages of being small in hardness, high in elasticity, good in vibration reducing performance, stable in size, excellent in mechanical property, good in softness and wearing comfortableness and the like and can be used for manufacturing shoe soles with the high requirements for the vibration reducing performance.

Owner:林树枫

Cooling structure of motor

ActiveCN110752713APractical to useSave energyCooling/ventillation arrangementSupports/enclosures/casingsElectric machineryEngineering

The invention discloses a cooling structure of a motor, which comprises a motor body, wherein the outer side of the motor body is provided with a main cooling mechanism, a connecting mechanism and anauxiliary cooling mechanism; the main cooling structure comprises a motor shaft, a first fixing ring, a first draft fan blade, a second fixing ring, a second draft fan blade, a third fixing ring, a third draft fan blade, a first bearing, a second bearing, a first rotating rod, a second rotating rod, a first bevel gear, a second bevel gear and a third bevel gear. According to the invention, the first bevel gear on the motor shaft and the second bevel gear and the third bevel gear on the motor body are arranged, and the three bevel gears can be driven to rotate when the motor shaft rotates, so that the first draft fan blade, the second draft fan blade and the third draft fan blade rotate are enabled to rotate, air draft is conducted from the upper side, the lower side and the right side at the same time to perform cooling on the motor. In addition, extra driving equipment is not needed, and energy is saved.

Owner:山东宇恒智能动力科技有限公司

Silicone get composition

InactiveCN1152898CGood shape retentionImprove vibration damping performanceOther chemical processesNon-rotating vibration suppressionSilicone GelsPolymer science

Owner:THREEBOND FINE CHEM CO LTD

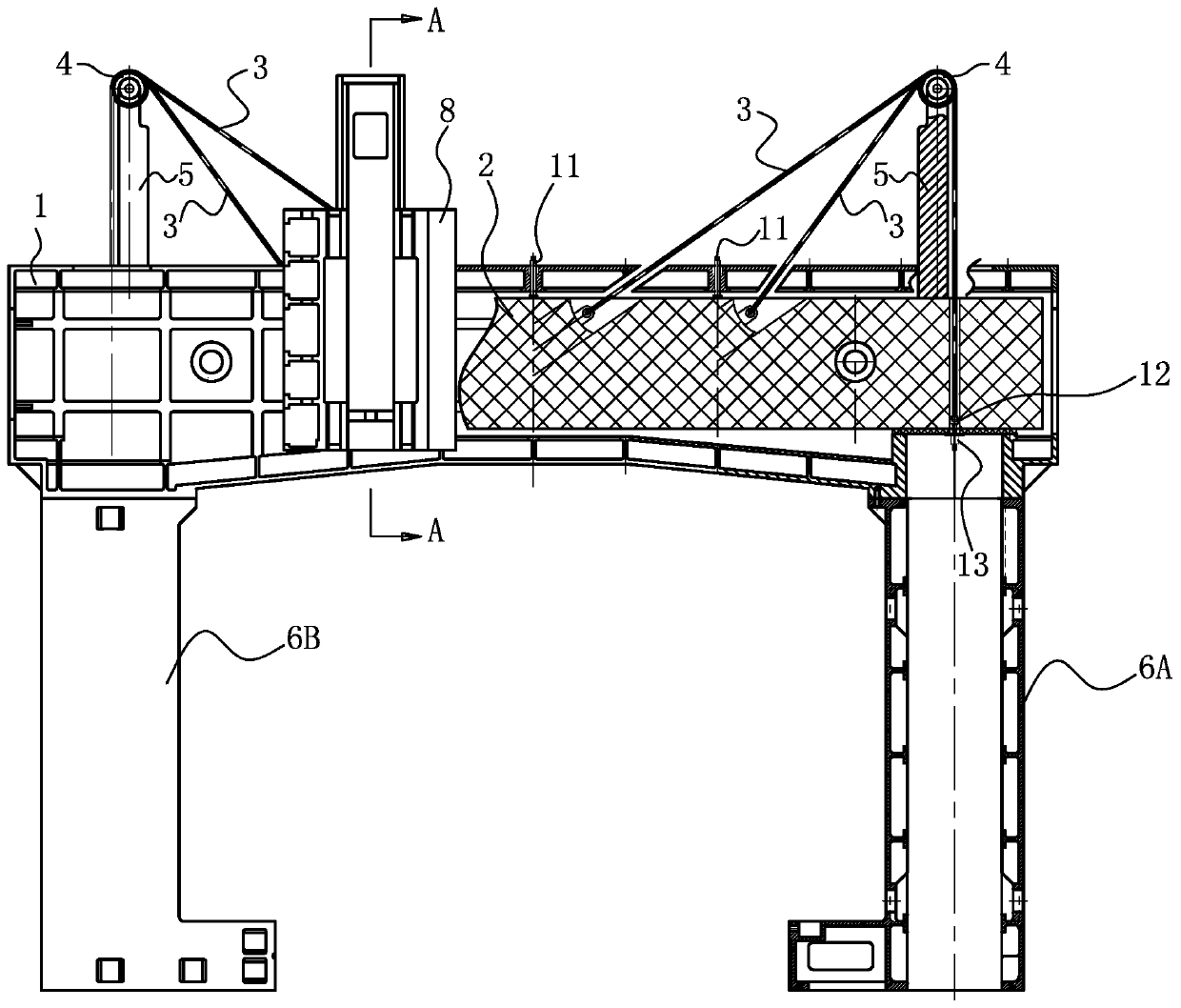

Large-span heavy gantry numerical control machine tool

PendingCN110877207ABalance deflectionImprove straightnessLarge fixed membersNumerical controlPolymer concrete

The invention discloses a large-span heavy gantry numerical control machine tool. An unloading beam made of polymer concrete materials is arranged in a hollow cavity of a beam of the large-span heavygantry numerical control machine tool. Supporting bases upwards penetrating through the beam are arranged at the two ends of the unloading beam correspondingly and provided with sliding wheels. A balance rope is wound around the sliding wheels, the first end of the balance rope is connected to the part, on the outer side, of the unloading beam, and the second end is connected to the part, on the inner side, of the unloading beam. According to the large-span heavy gantry numerical control machine tool, on one hand, the middle portion of the unloading beam can be upwards jacked by adjusting thetightness of the balance rope, the force is transmitted to the beam through an adjusting screw, the deflection of the beam can be effectively balanced, the moving linearity of a transverse moving sliding base on the beam is improved, and accordingly the machining precision of the machine tool is improved; and on the other hand, good strength of stand columns and the beam made of cast iron materials is sufficiently utilized, due to the character of excellent vibration damping performance of the unloading beam and a supporting core column made of the polymer concrete materials, vibration absorption is accelerated, the two parts are combined, and mutual complementation is achieved.

Owner:高密宏泰机床制造有限公司

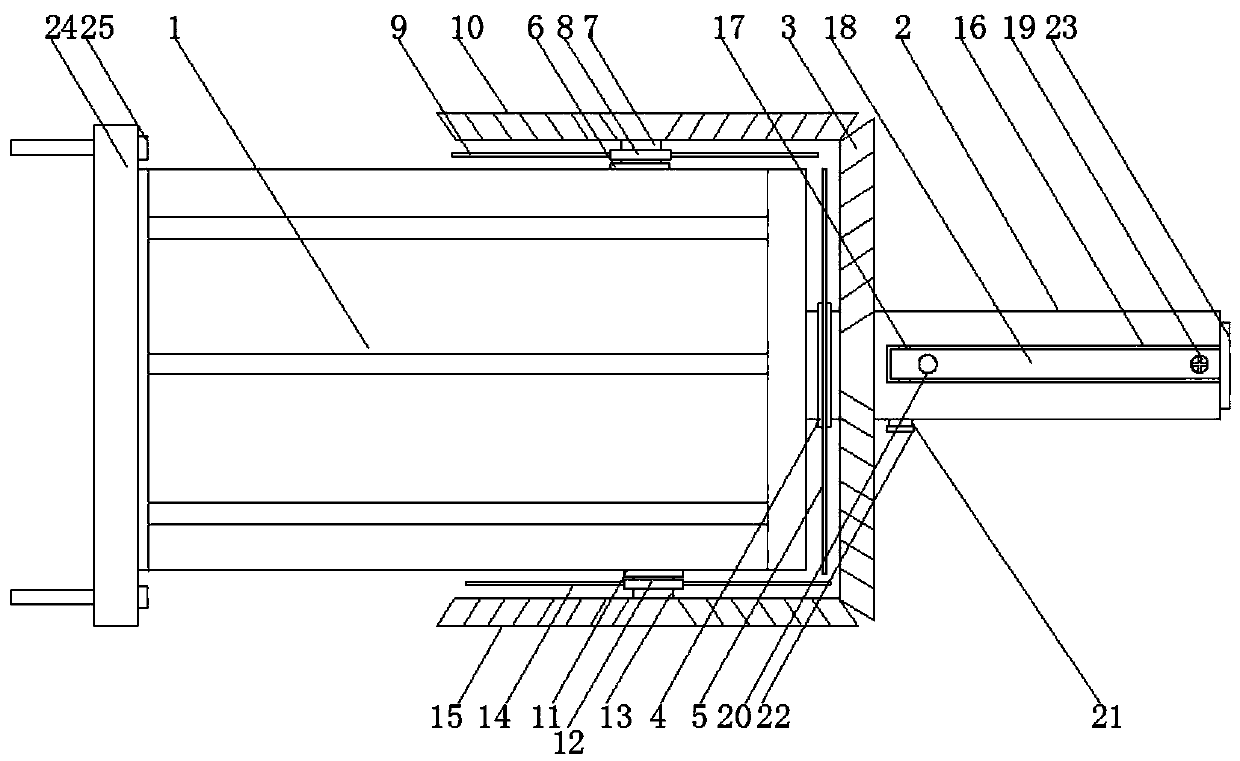

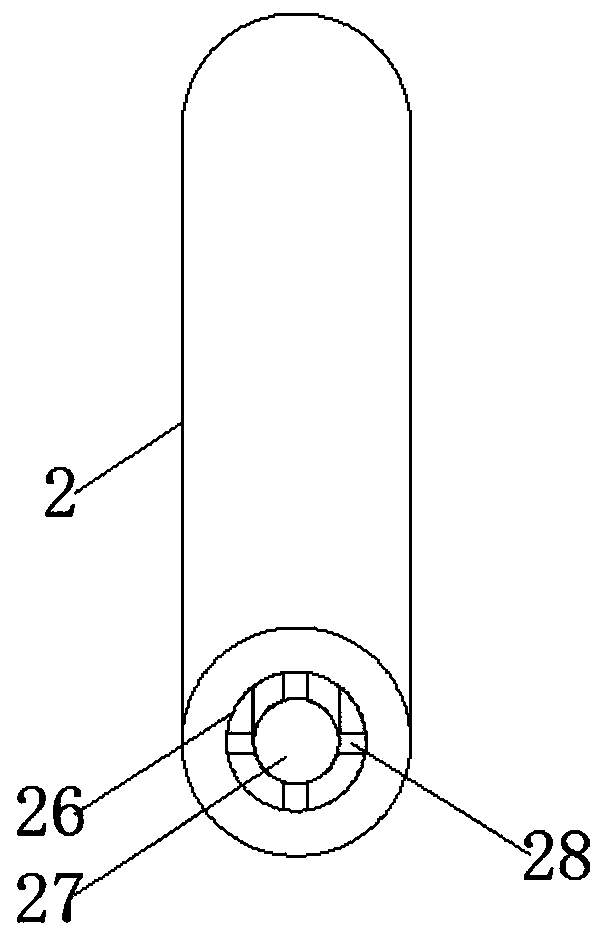

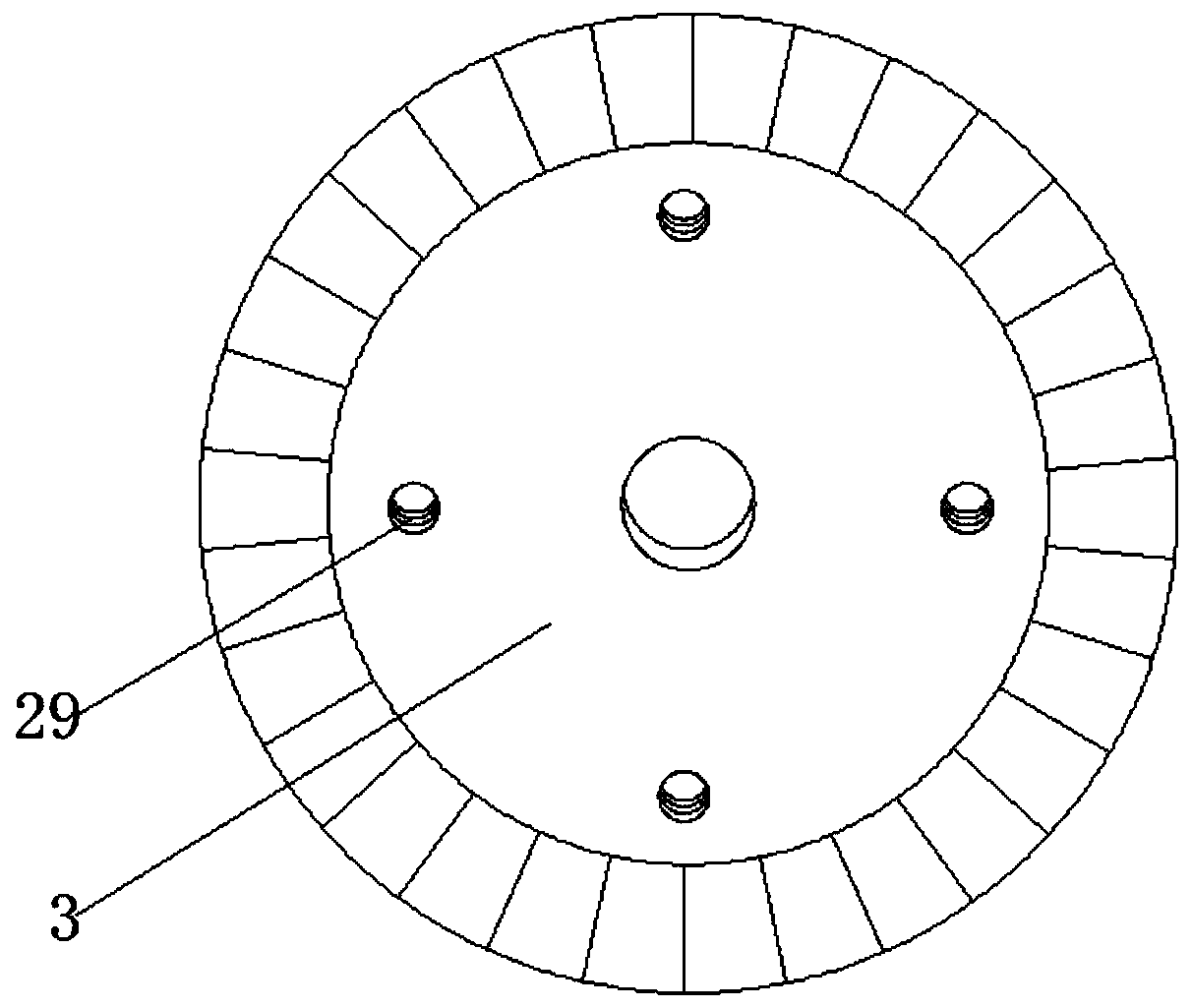

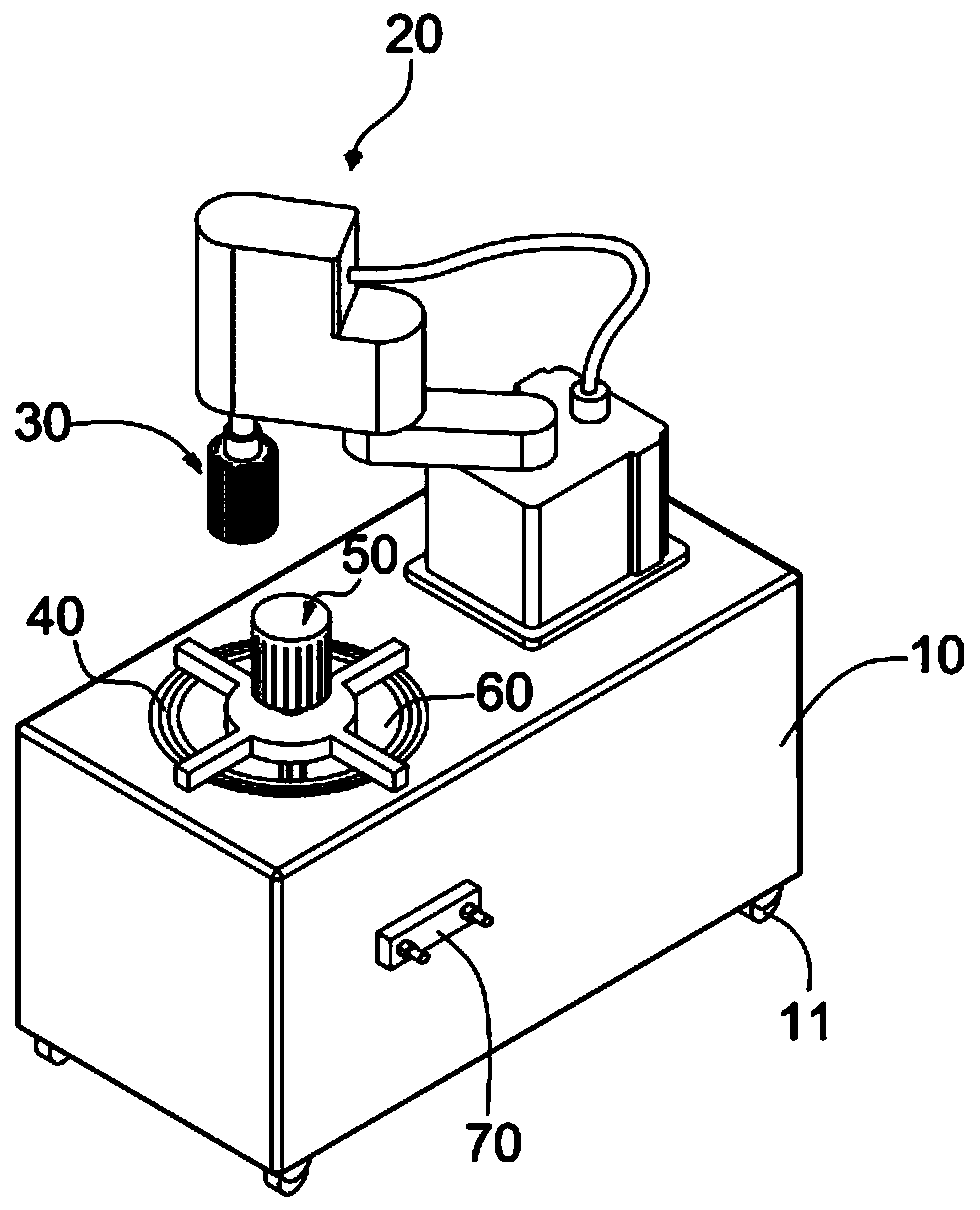

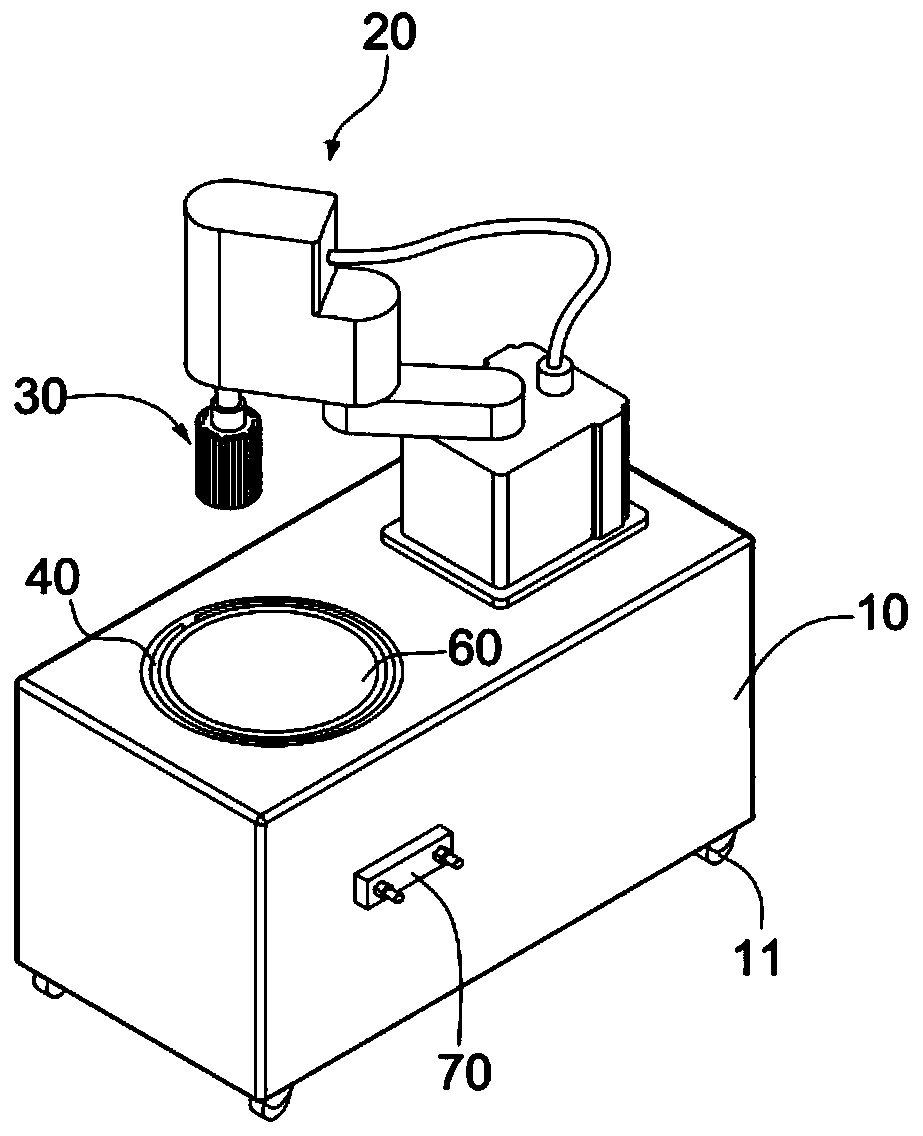

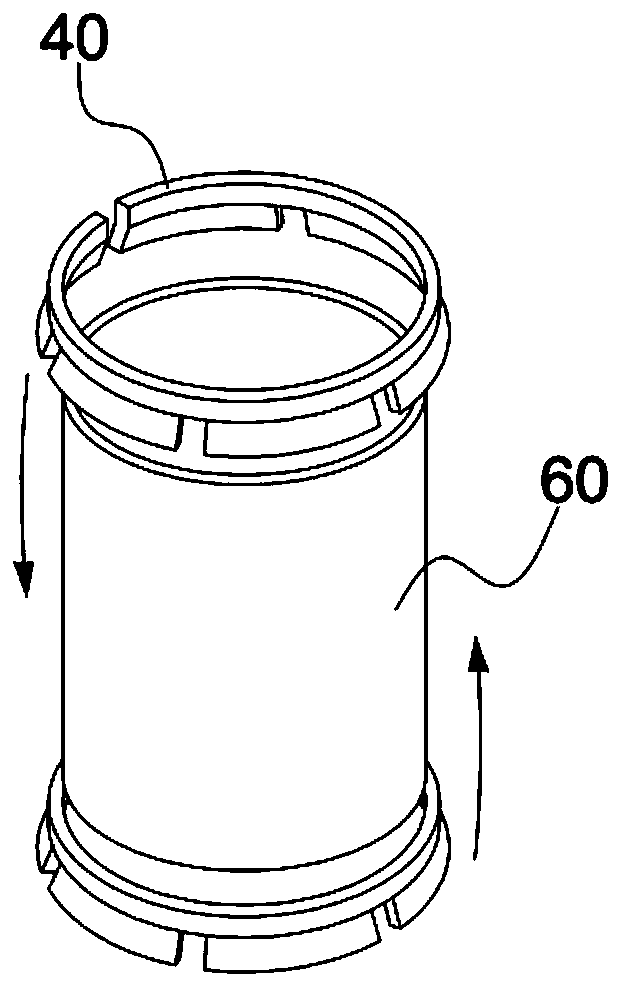

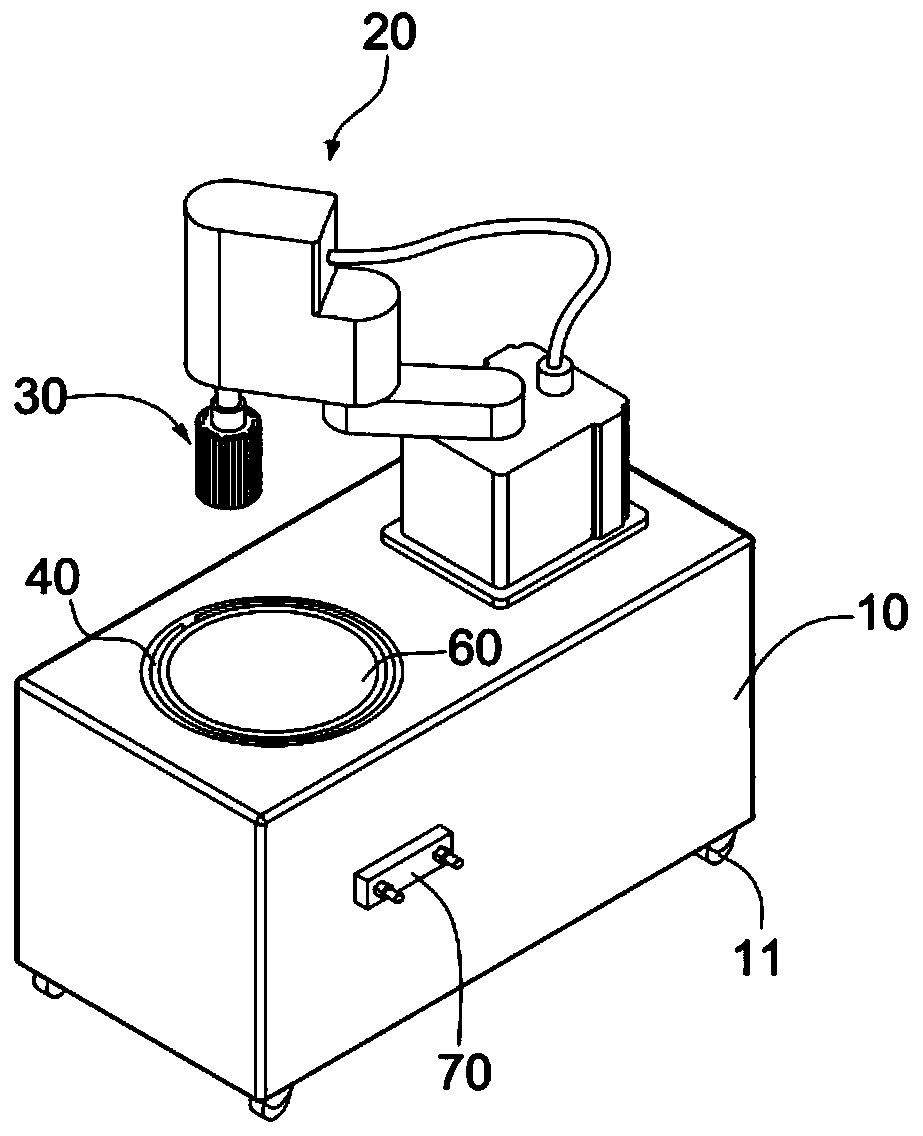

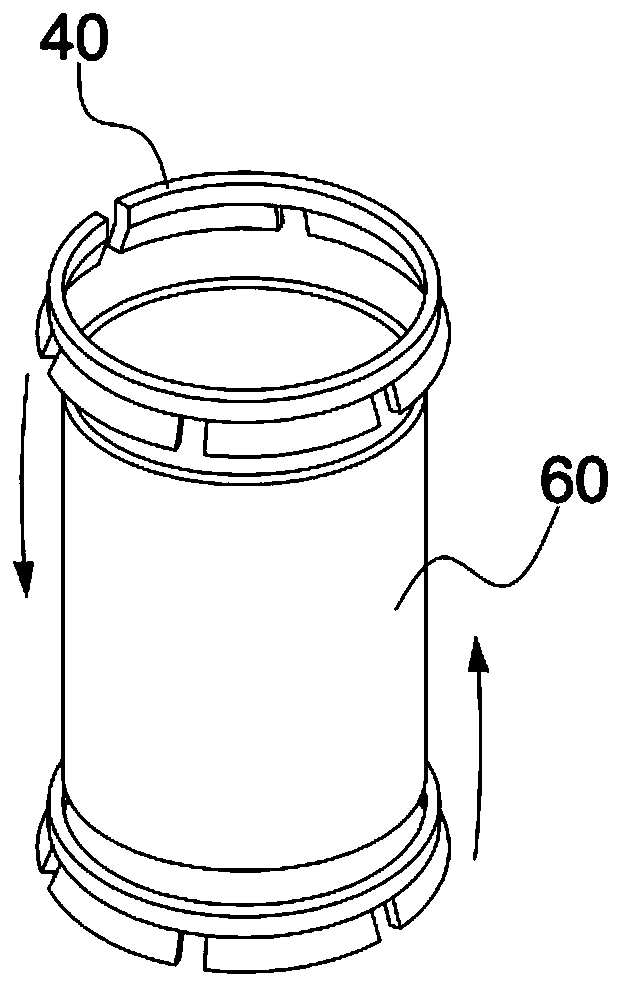

Centrifugal device for treating inner surface of pipe

ActiveCN110370109AQuality improvementReduce the use of laborGrinding machine componentsRevolution surface grinding machinesSurface finishingFastener

The invention discloses a centrifugal device for treating the inner surface of a pipe, and belongs to the technical field of pipe processing. The device comprises a base body and a mechanical arm; thebase body is provided with a through hole for placing the pipe; the mechanical arm is mounted on the base body and is used for clamping a polishing assembly and driving the polishing assembly to rotate to polish the inner wall of the pipe, and a gap between the pipe and the through hole in the base body is filled with a fastening piece; and the fastening piece comprises a first ring body connected to the outer wall of the pipe in a sleeving manner, the first ring body is connected with a coaxial second ring body, the upper and lower ends of the second ring body are unequal in diameter, the end with the smaller diameter is connected to the first ring body and is equal to the first ring body in diameter, the second ring body is divided into a plurality of segments from a notch, and a notchin the first ring body corresponds to the notch in the second ring body. According to the centrifugal device, in the process of treating the inner surface of the pipe, the vibration of the pipe is effectively reduced, the rate of adhesion between cleaning debris on the inner surface of the pipe and the inner wall of the pipe is low, and the quality of the inner surface of the processed pipe is high.

Owner:杭州富阳锋拓机械有限公司

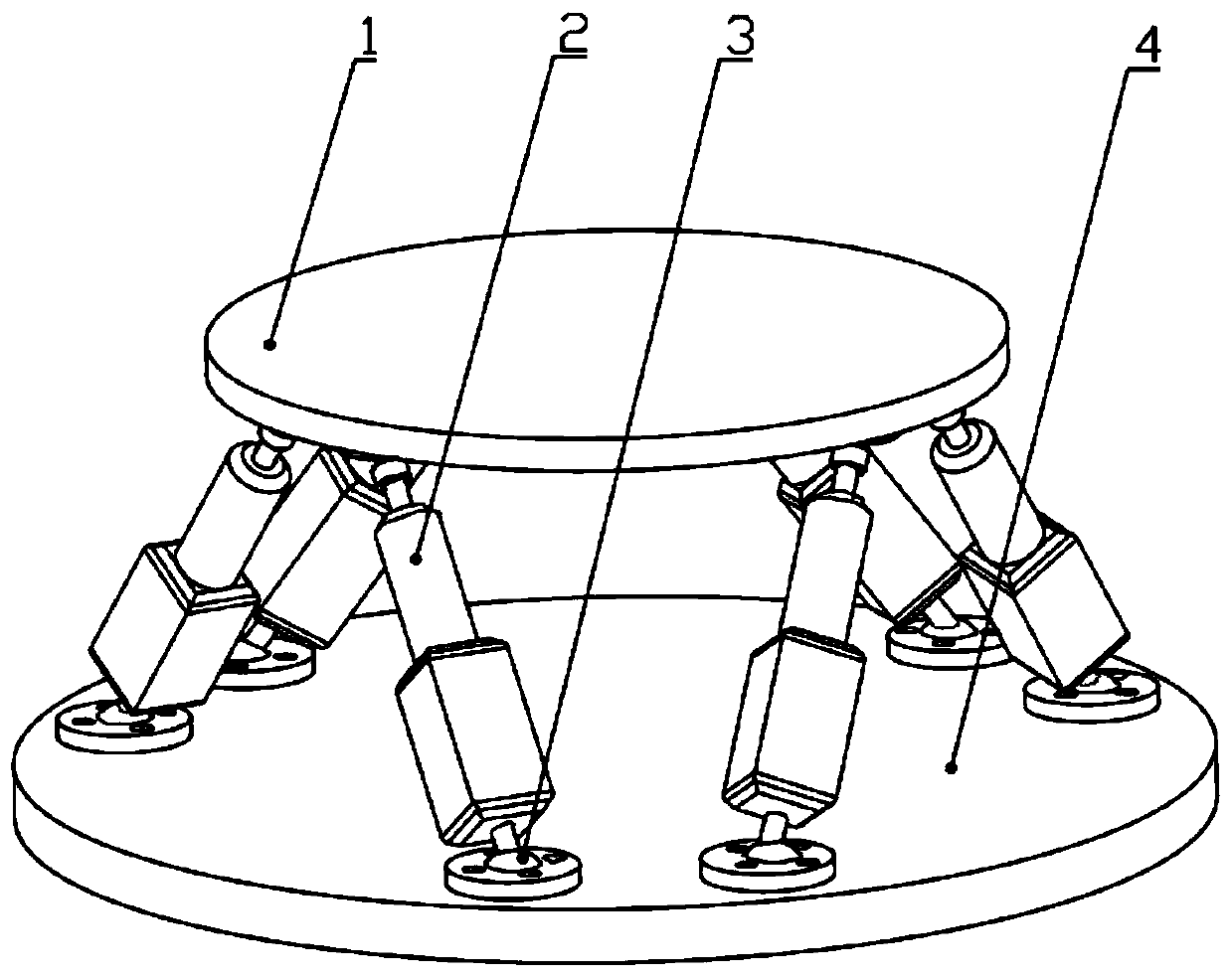

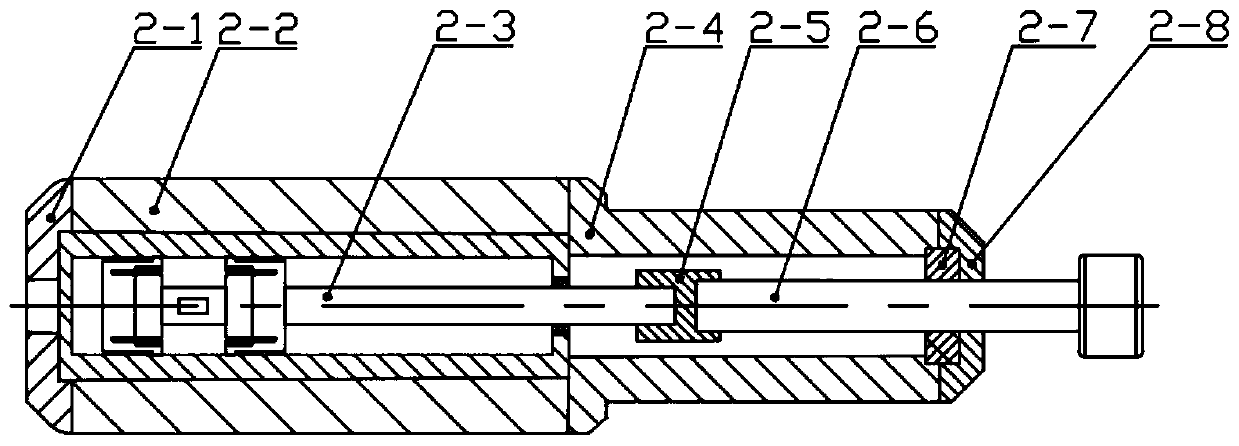

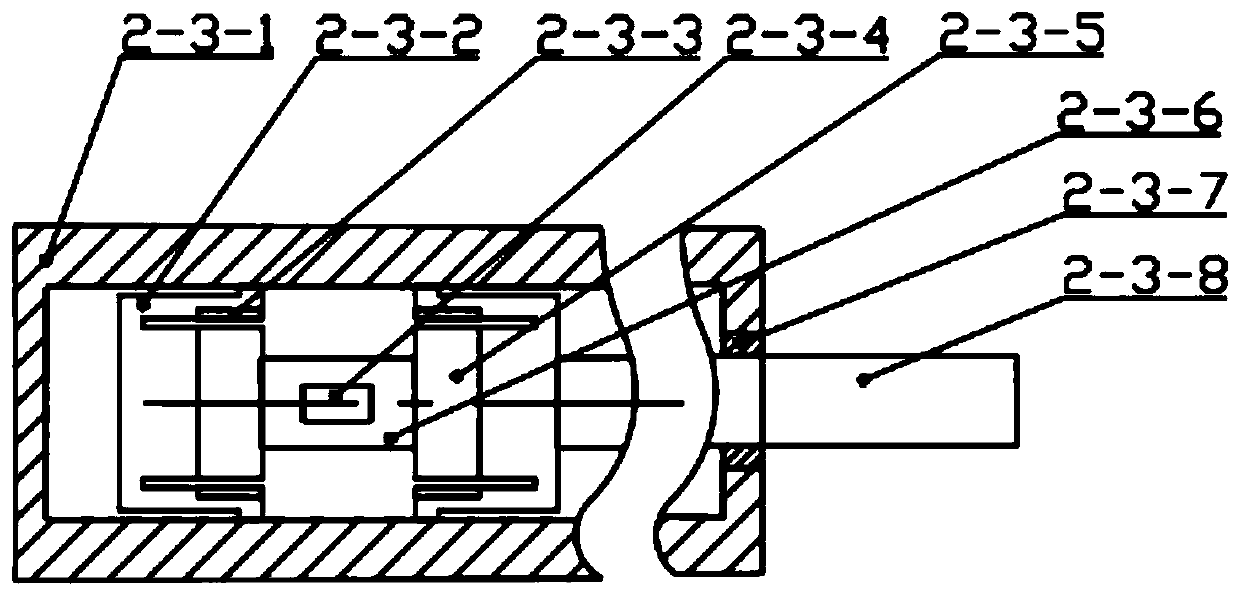

Multi-state parallel multi-degree-of-freedom motion platform based on piezoelectric driving

ActiveCN111216108ACompact structureReduce volumeProgramme-controlled manipulatorSpherical bearingDrive by wire

The invention discloses a multi-state parallel multi-degree-of-freedom motion platform based on piezoelectric driving, and belongs to the technical field of motion mechanics. The multi-state parallelmulti-degree-of-freedom motion platform based on piezoelectric driving has two motion states of stepping and scanning. The multi-state parallel multi-degree-of-freedom motion platform based on piezoelectric driving comprises a static platform, a moving platform placed coaxially parallel to the static platform and six linear driving assemblies disposed between the static platform and the moving platform, and two ends of each linear driving assembly are connected with the lower end surface of the moving platform and the upper end surface of the static platform through spherical bearings; the linear driving assemblies comprises end covers, actuator protective shells, piezoelectric inchworm-type actuators, couplings, bearings, output shafts, output shaft shells and bearing end covers. The piezoelectric inchworm-type actuators comprise tracks, flexible members, armatures, electromagnets, elongated piezoelectric stacks, strain gauges, axle sleeves and actuating shafts. Clamping mechanisms comprise electromagnets, armatures and flexible members. The strain gauges are pasted on the elongated piezoelectric stacks, one ends of the actuating shafts are fixed to the back of one of the clampingmechanisms, and the other ends of the actuating shafts are supported by the axle sleeves.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Noise damping composition

InactiveCN102558840BImprove vibration damping performanceEnhanced inhibitory effectMaterial nanotechnologyPolymer sciencePolyamide

Disclosed are thermoplastic compositions having excellent vibration damping and noise suppression properties and molded articles made therefrom that can be manufactured inexpensively. The noise damping compositions of the present invention being (a) about 50-85 weight % of a polyamide; (b) about 5-45 weight % of a fibrous reinforcing agent; (c) about 1-25 weight % of zinc oxide; and (d) about 0-15 weight % of other additive; wherein the weight % is based on the total weight of the noise damping composition, and provided that the composition has essentially no flame retardants.

Owner:EI DU PONT DE NEMOURS & CO

Vibration damping siloxane composition

InactiveCN1273541CImprove vibration damping performanceGood storage stabilitySpringsOther chemical processesEngineeringHydrophobic silica

A vibration damping silicone composition that exhibits an excellent vibration damping performance and long-term storage stability comprising a silicone oil, a silicone resin powder that is solid at room temperature, and a surface-hydrophobic silica powder having a pH of greater than 6 but less than 9. The composition is particularly useful in shock absorbers for electronic and / or electrical equipment such as compact disk players, compact disk changers, mini-disk players, and car navigation devices.

Owner:DOW CORNING TORAY SILICONE CO LTD

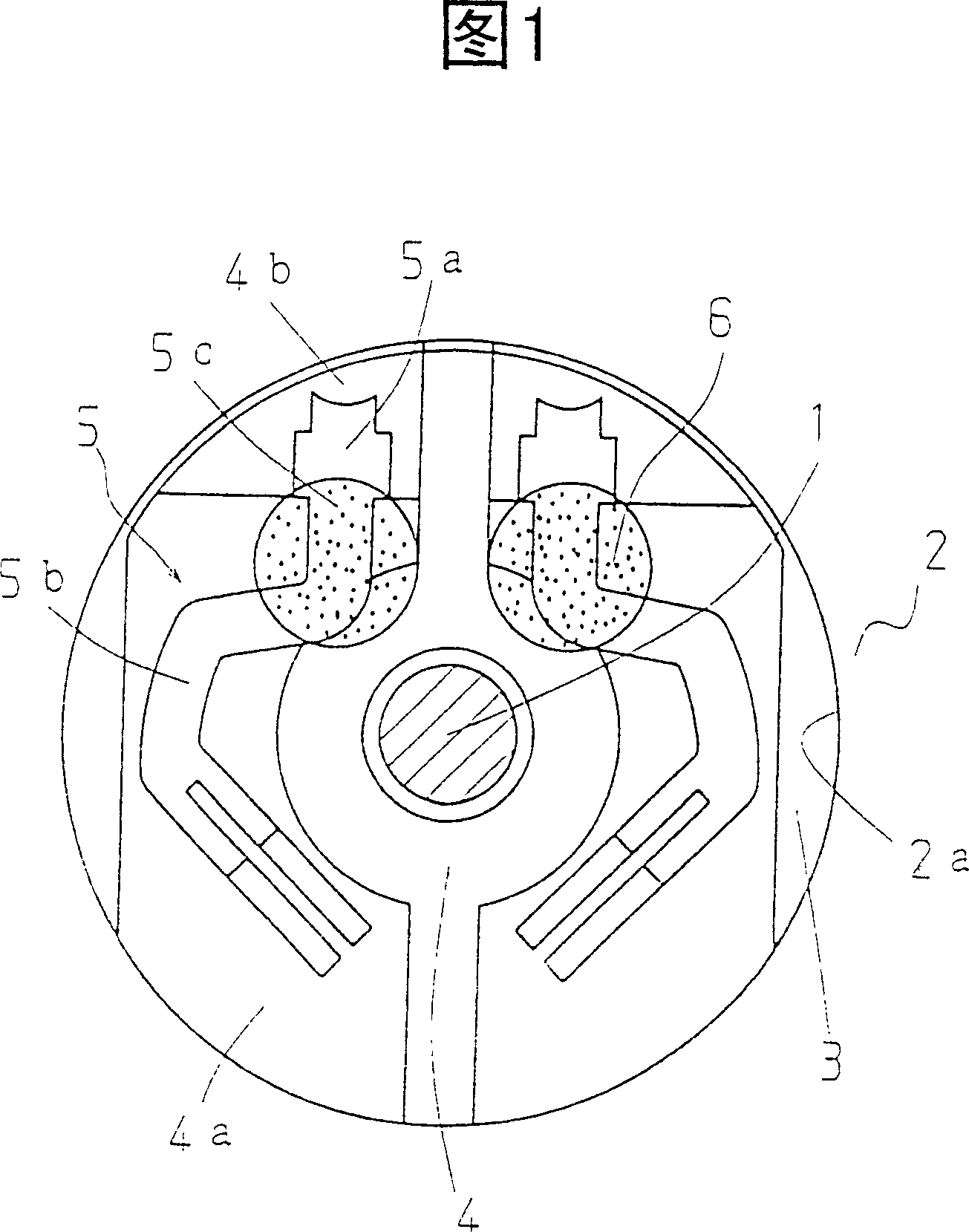

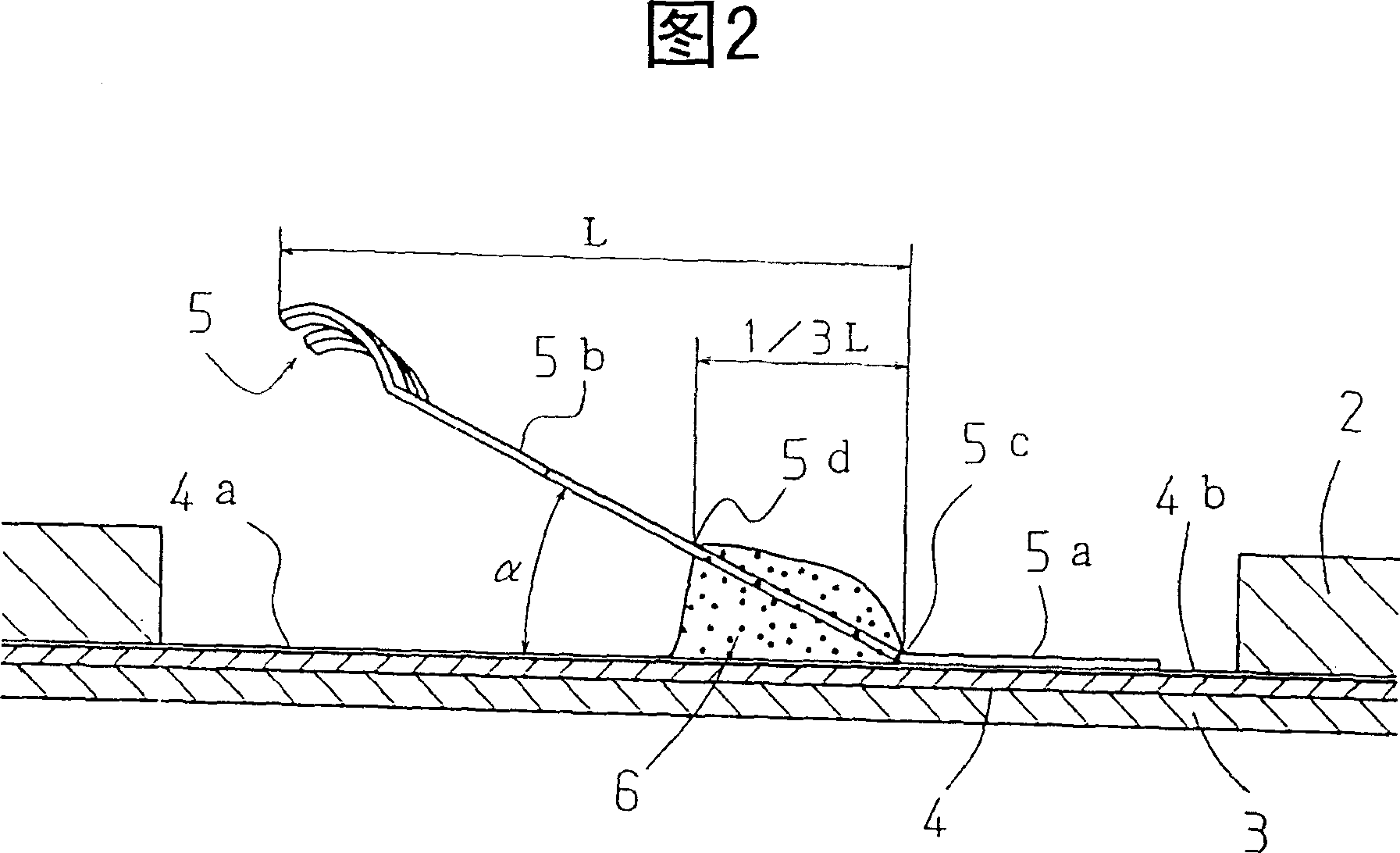

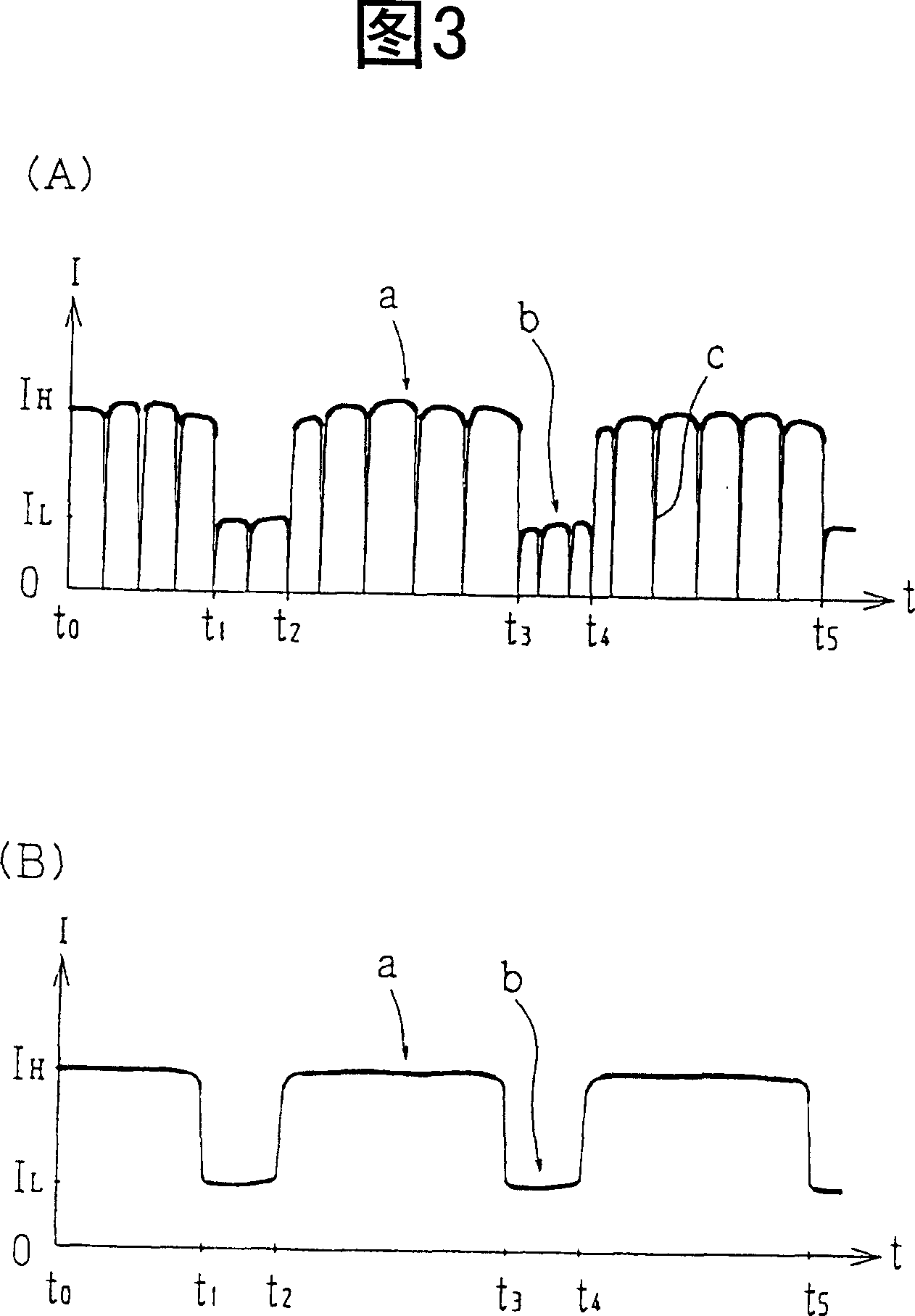

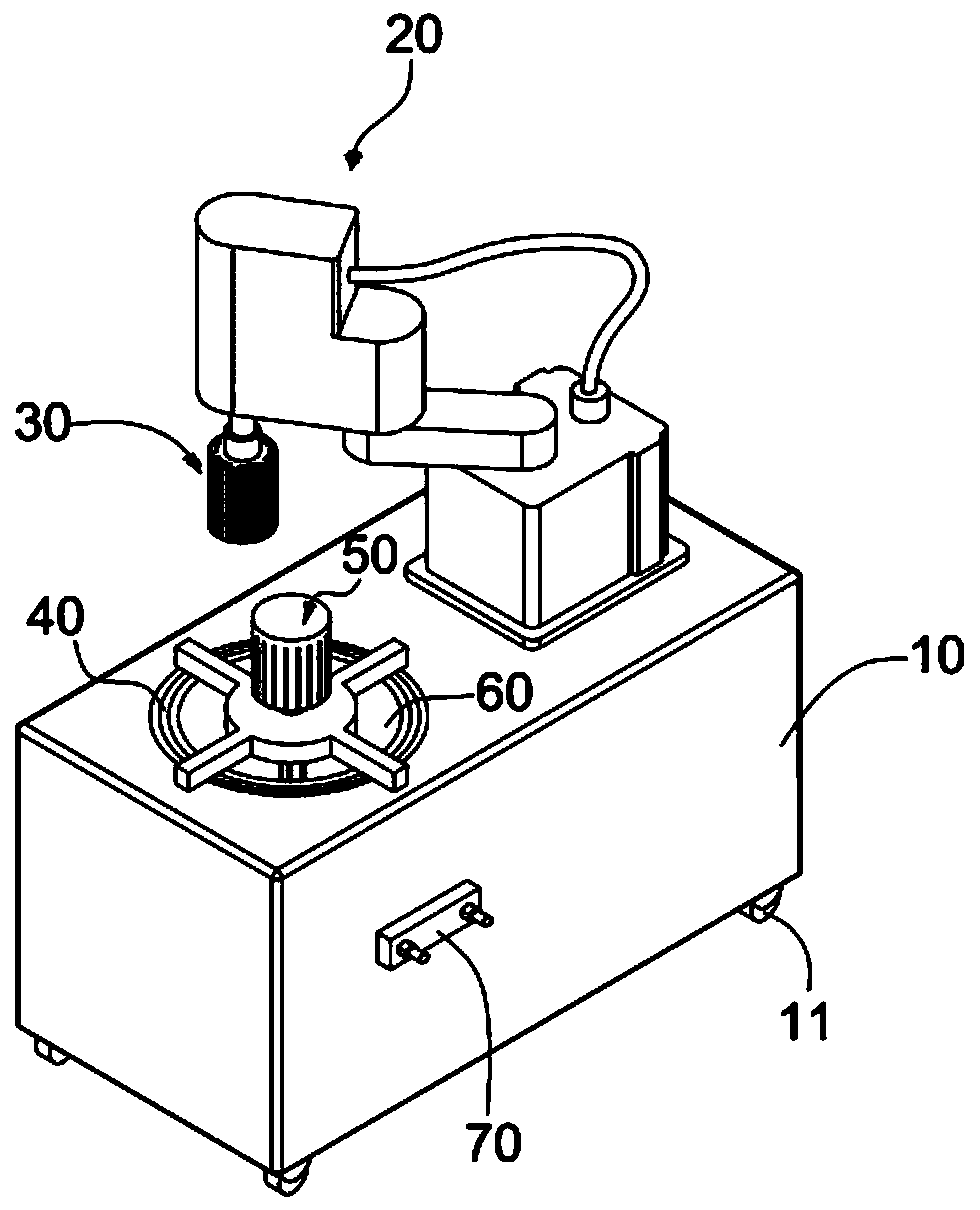

Axially sliding connection brush appliance, its mfg. method and dynamo set with same brush

InactiveCN1311610CImprove vibration damping performanceEasy softnessRotary current collectorDC commutatorElevation angleEngineering

The object of this invention is to prevent damage to the vibration damping property of a brush even for a violent vibration, and to enable frequently a stale contact between the brush and a commutator. The brush (5) is disposed at an elevation angle less than 45 degrees relative to a brush base (4) fixed to a bracket (3) such that the free end thereof is connected slidably to a flat commutator. The flat portion (5a) of the base portion of the brush is fixed to the exposed portion (4b) of the pattern (4a) of the brush base 4 by soldering. The base portion of the brush is coated with ultraviolet curable acrylic-based resin (6) to cover, at a maximum, about 1 / 3 of the projection length of the side face from the base portion to the brush arm portion of the brush.

Owner:TOKYO PARTS IND CO LTD

Centrifugal equipment for internal surface treatment of pipes

ActiveCN110370109BConsistent round beatingNo fallingGrinding machine componentsRevolution surface grinding machinesEngineeringPipe

The invention discloses a centrifugal device for treating the inner surface of a pipe, and belongs to the technical field of pipe processing. The device comprises a base body and a mechanical arm; thebase body is provided with a through hole for placing the pipe; the mechanical arm is mounted on the base body and is used for clamping a polishing assembly and driving the polishing assembly to rotate to polish the inner wall of the pipe, and a gap between the pipe and the through hole in the base body is filled with a fastening piece; and the fastening piece comprises a first ring body connected to the outer wall of the pipe in a sleeving manner, the first ring body is connected with a coaxial second ring body, the upper and lower ends of the second ring body are unequal in diameter, the end with the smaller diameter is connected to the first ring body and is equal to the first ring body in diameter, the second ring body is divided into a plurality of segments from a notch, and a notchin the first ring body corresponds to the notch in the second ring body. According to the centrifugal device, in the process of treating the inner surface of the pipe, the vibration of the pipe is effectively reduced, the rate of adhesion between cleaning debris on the inner surface of the pipe and the inner wall of the pipe is low, and the quality of the inner surface of the processed pipe is high.

Owner:杭州富阳锋拓机械有限公司

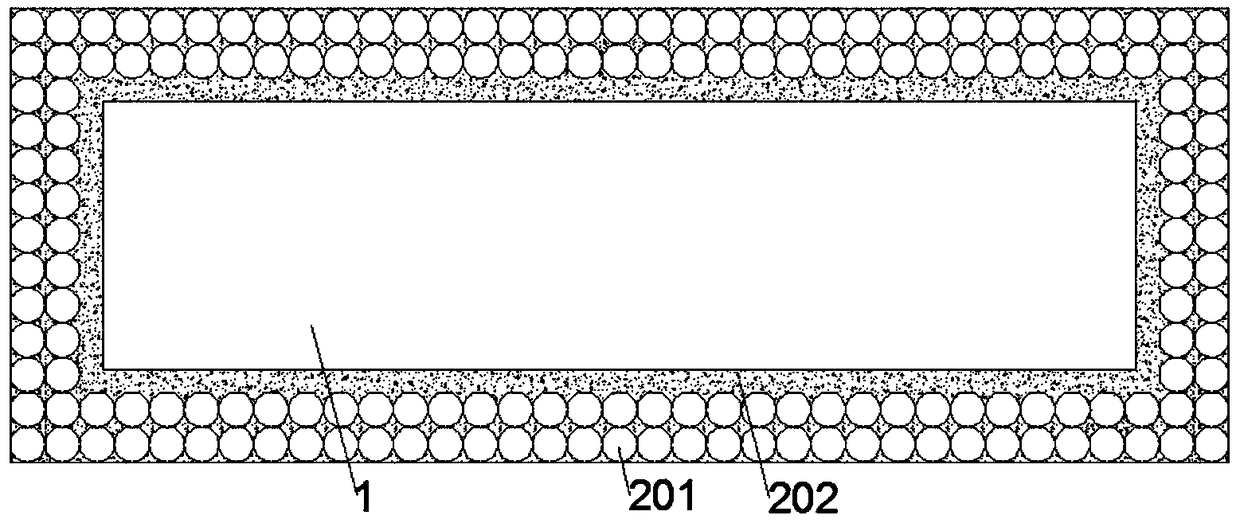

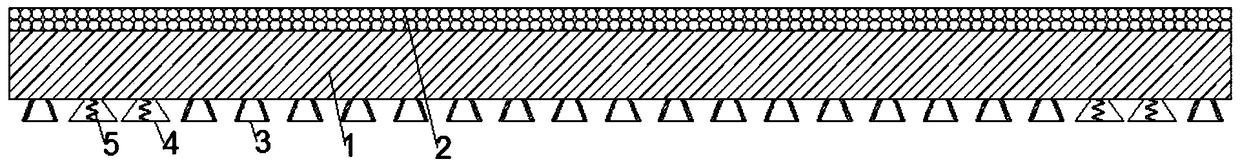

Shock absorbing pad for treadmill and preparation method thereof

PendingCN109260692AImprove vibration damping performanceImprove wear resistanceMovement coordination devicesCardiovascular exercising devicesHollow corePerlite

The invention discloses a shock absorbing pad for a treadmill and a preparation method thereof, belonging to the field of shock absorbing pads. A treadmill shock absorbing pad includes a rubber lay, asound-adsorbing layer and a buffer layer. The sound-absorbing layer is arranged at the upper end of the rubber layer, the buffer layer is arranged at the lower end of the rubber layer, the rubber layer is rectangular, the buffer layer comprises four groups of rubber seats and a plurality of adsorption disks, the four groups of rubber seats are respectively arranged at four right angles of the lower end of the rubber layer, and each group of rubber seats comprises 4-8 round table-shaped rub bases, wherein a spring is arranged in that round table-shaped rubber bases, the adsorption disk is uniformly arranged at the lower end of the rubber layer, the sound-absorbing layer is in the shape of a square ring, and the sound-absorbing layer is composed of hollow glass micro beads and expanded perlite. The treadmill shock absorbing pad has excellent vibration absorbing performance and sound absorbing performance, and is suitable for use in a gym and a treadmill in a family.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com