Vibration damping siloxane composition

A technology of vibration damping and composition, applied in the field of vibration damping siloxane composition, can solve the problems such as the reduction of vibration damping performance, and achieve the effects of low responsiveness, excellent storage stability, and excellent vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

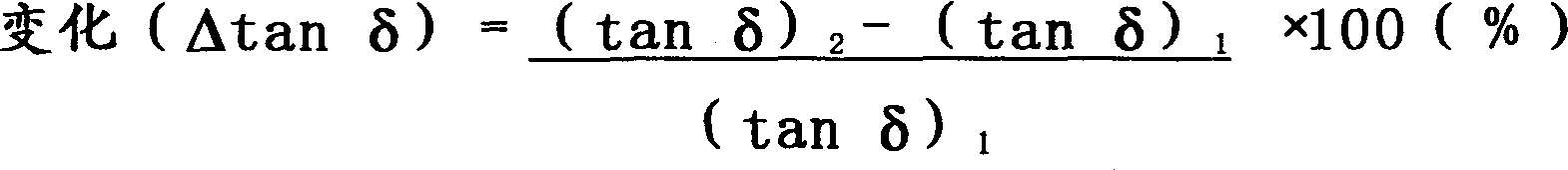

[0034] 1000g viscosity is 10,000mm 2 / s of trimethylsiloxy-terminated dimethylpolysiloxane, 460 g consisting only of CH 3 SiO 3 / 2 Methyl polysilsesquioxane powder (average particle diameter = 20 μm) composed of siloxane units and 30 g of surface hydrophobic wet-process silica powder (pH = 7) prepared in Reference Example 1 were added to the Ross mixer middle. The resulting mixture was homogenized by scraping with a Ross mixer at low speed (150 rpm). The homogeneous mixture was then further mixed and kneaded for 2 hours under reduced pressure (100 mmHg). The viscosity of the obtained silicone composition was 70 Pa·s. The vibration damping properties of the silicone compositions were measured at 25°C and 60°C. The silicone composition was then stored for 3 months before its vibration damping properties were measured at 25°C. The change in vibration damping performance can be calculated by the following formula. Various results are listed in Table 1.

[0035]

[0036] ...

Embodiment 2

[0040] 1000g viscosity is 30,000mm 2 / s of trimethylsiloxy-terminated dimethylpolysiloxane, 800g consisting only of CH 3 SiO 3 / 2 Methyl polysilsesquioxane powder (average particle diameter = 20 μm) composed of siloxane units and 25 g of surface hydrophobic wet-process silica powder (pH = 7) prepared in Reference Example 1 were added to the Ross mixer middle. The resulting mixture was homogenized by scraping with a Ross mixer at low speed (150 rpm). The homogeneous mixture was then further mixed and kneaded for 2 hours under reduced pressure (100 mmHg). The viscosity of the obtained silicone composition was 1000 Pa·s.

[0041] The vibration damping properties of the silicone composition were measured as described in Example 1 for immediate (tan δ) 1 and (tanδ) after a three-month aging period 2 To measure the change of its vibration damping performance (Δtanδ). These results are listed in Table 1. The viscosity of the silicone composition was measured after storage for ...

Embodiment 3

[0043] 1000g viscosity is 20,000mm 2 / s of trimethylsiloxy-terminated dimethylpolysiloxane, 500g consisting only of CH 3 SiO 3 / 2 Methyl polysilsesquioxane powder (average particle diameter = 20 μm) composed of siloxane units and 30 g of surface hydrophobic wet-process silica powder (pH = 7) prepared in Reference Example 1 were added to the Ross mixer middle. The resulting mixture was homogenized by scraping with a Ross mixer at low speed (150 rpm). The homogeneous mixture was then further mixed and kneaded for 2 hours under reduced pressure (100 mmHg). The viscosity of the obtained silicone composition was 500 Pa·s.

[0044] The vibration damping properties of the silicone composition were measured as described in Example 1 for immediate (tan δ) 1 and (tanδ) after a three-month aging period 2 To measure the change of its vibration damping performance (Δtanδ). These results are listed in Table 1. The viscosity of the silicone composition was measured after storage for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com