Centrifugal equipment for internal surface treatment of pipes

A centrifugal equipment and inner surface technology, which is applied in the field of pipe processing, can solve the problems of low removal efficiency of iron oxide scale and low surface quality of the inner pipe of the pipe, and achieve the effect of improving the processing efficiency of the pipe, reducing the labor intensity of the personnel and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

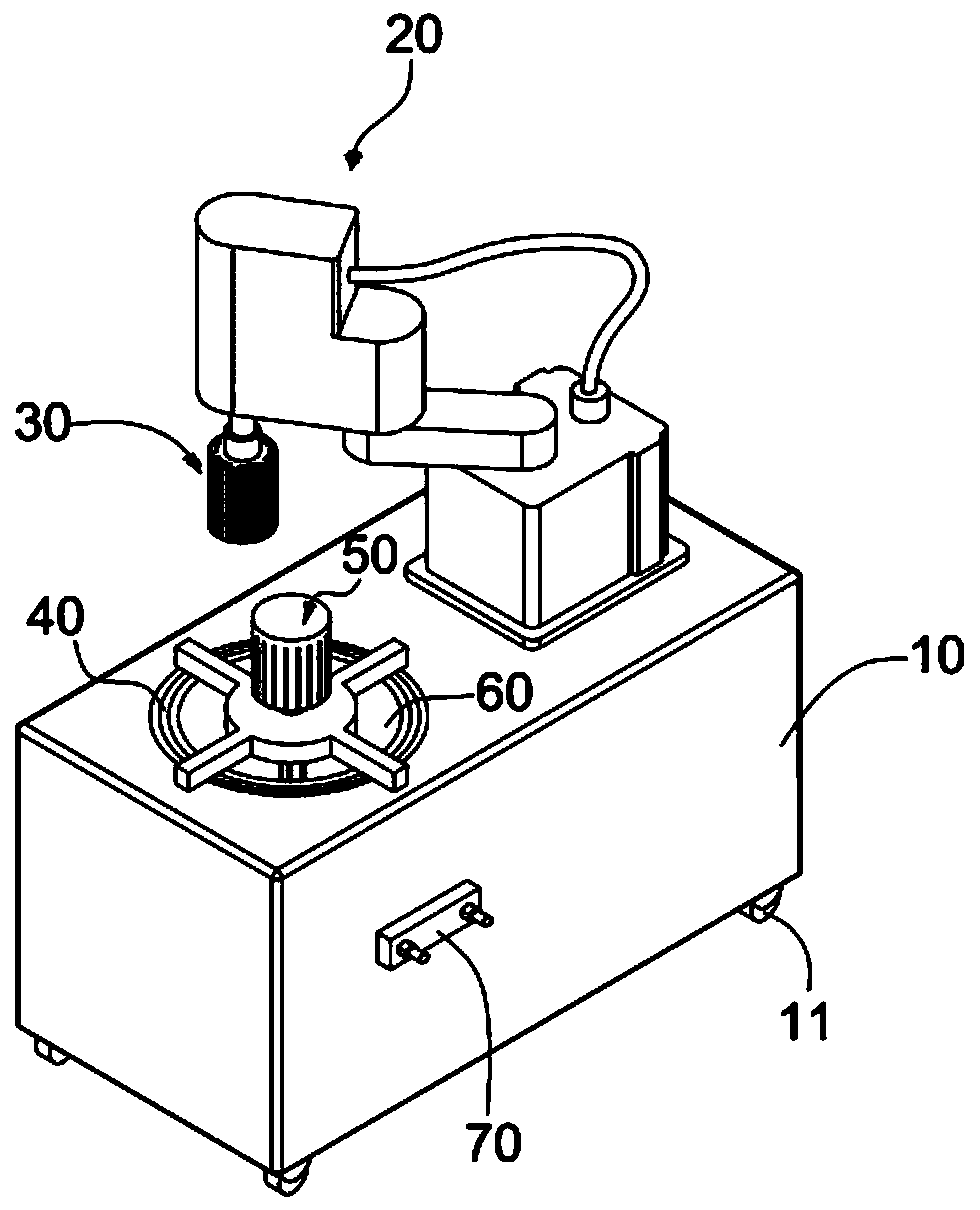

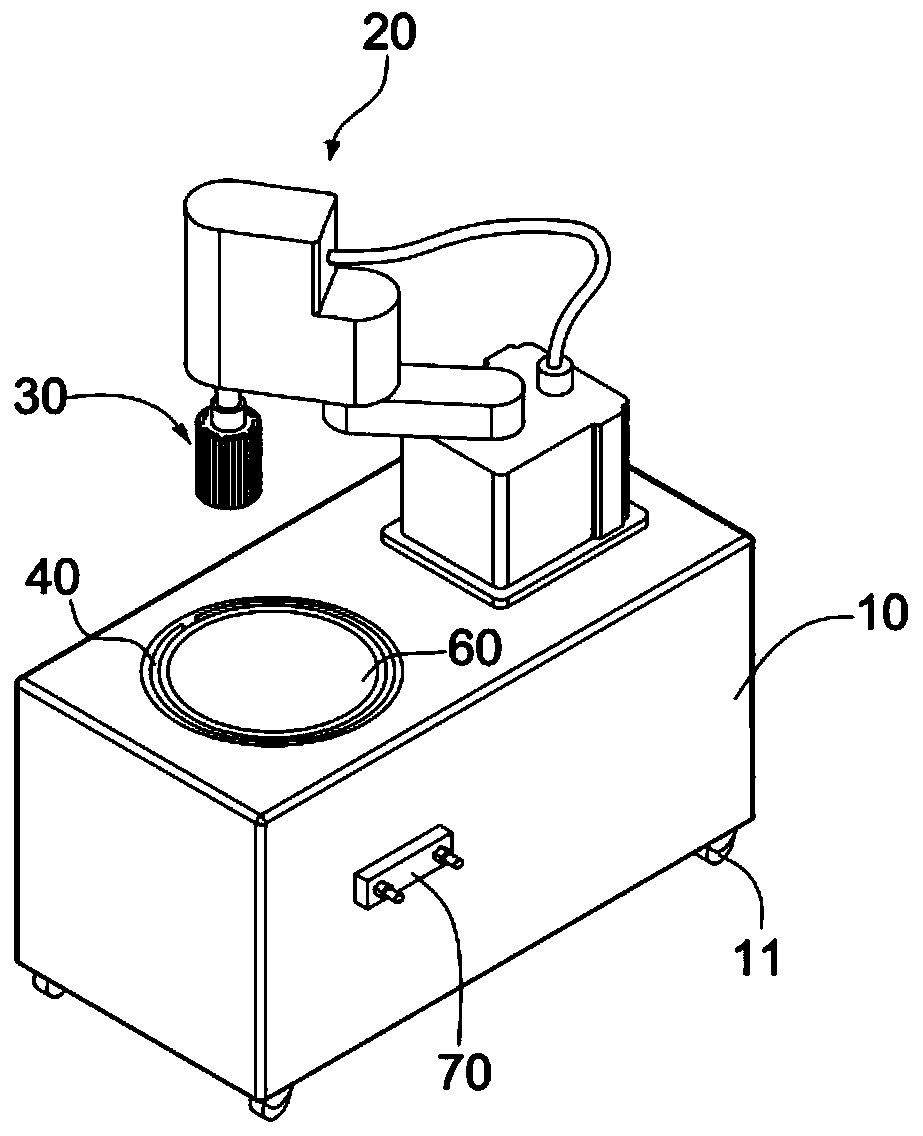

[0040] see Figure 1-9 As shown, the centrifugal equipment used for the inner surface treatment of pipes includes:

[0041] The base body 10 has a through hole for placing the pipe material 60 on the base body 10,

[0042] The manipulator 20 is installed on the substrate 10, and the manipulator 20 is used to clamp the grinding assembly 30 and drive the grinding assembly 30 to rotate to grind the inner wall of the pipe 60,

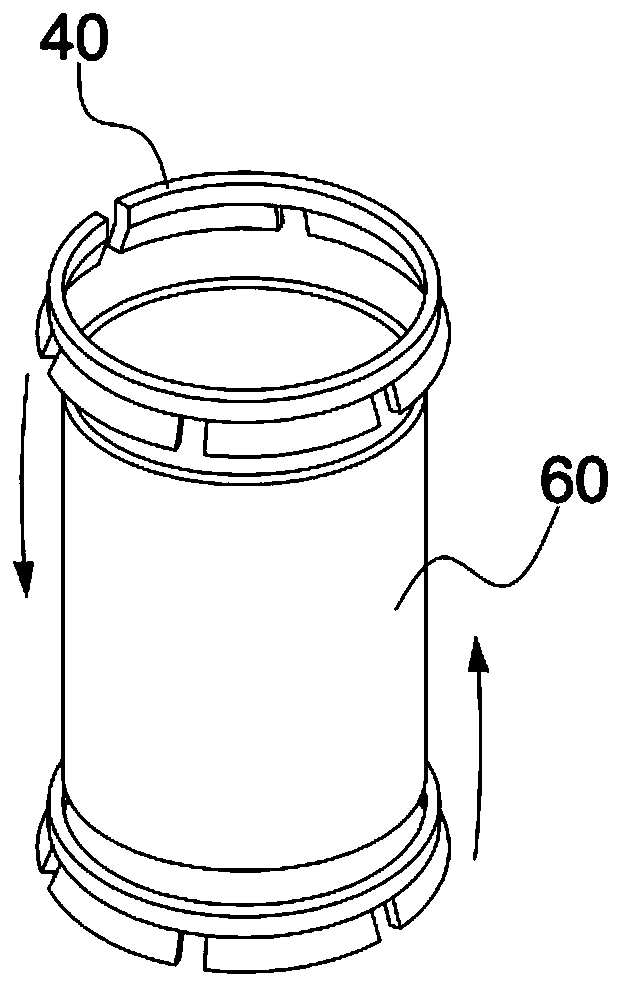

[0043] Wherein, the gap between the pipe material 60 and the through hole on the base body 10 is filled with the fastener 40, the fastener 40 includes a first ring body 41 sleeved on the outer wall of the pipe material 60, the first ring body 41 is connected with a coaxial second The ring body 42, the diameter of the upper and lower ends of the second ring body 42 is not equal, the smaller diameter end is connected with the first ring body 40 and is equal in diameter, the second ring body 42 is separated by a notch 43 into several sections, and the first r...

Embodiment 2

[0060]The substrate 10 in the centrifugal equipment used for the inner surface treatment of pipes in the present invention can be a frame or other substrates for supporting and assembling parts, and should not be limited to its structural shape. The diameter of the through hole on the substrate 10 is larger than the processed pipe 60 Outer diameter, the specific size is selected according to the actual processing situation. The manipulator 20 referred to in the present invention is a manipulator with clamping and driving shaft workpiece rotation. This is an existing common technical means and should be understood by those skilled in the art , the material of the grinding sleeve 34 and the grinding bar 33 in the present invention should be reasonably selected according to the material of the pipe fitting 60 to be polished, for example, when the pipe 60 of 45 steel material is processed and the grinding sleeve 34 and the grinding bar prepared by diamond abrasives are selected. 33...

Embodiment 3

[0062] When the centrifugal equipment for the inner surface treatment of pipes of the present invention is actually used: after the fastener 40 is sleeved on the outer surface of the pipe 60, the pipe 60 is pressed into the through hole on the base 10, and a rubber hammer can be selected during the pressing process. Knock the pipe 60 to make it easy to enter the through hole in the base body 10, and then tighten the nut on the outside of the clamping block 70 to reduce the gap between the clamping block 70 and the pipe 60 during the nut tightening process. After clamping the pipe 60, after the positioning and clamping of the pipe 60 are completed, the manipulator 20 clamps the grinding assembly 30 and drives the grinding assembly 30 to rotate to grind the inner wall of the pipe 60. After finishing the grinding process, the inner wall of the pipe is brushed by the brush assembly 50 Carry out oiling or painting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com