Microporous elastomer with high vibration reducing performance and preparation method thereof

A microporous elastomer and performance technology, applied in the field of microporous elastomer and its preparation, can solve problems such as unsatisfactory vibration damping performance, achieve dimensional stability, improve mechanical properties, and good vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

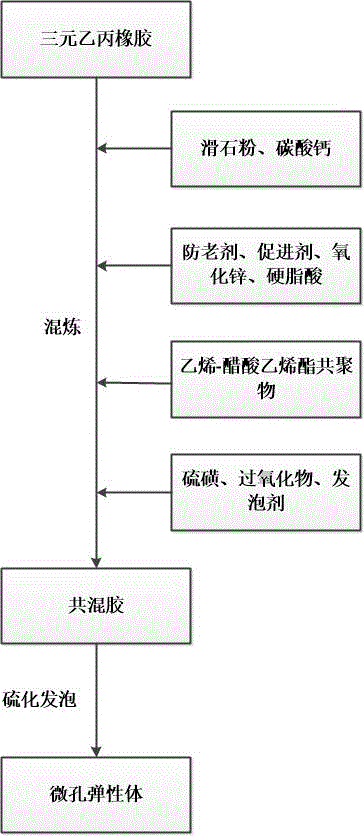

[0021] A kind of preparation method of the microporous elastomer with high damping performance of the present invention, comprises the following steps:

[0022] Step 1: After blending EPDM rubber, talcum powder, and calcium carbonate on an open mill, adding anti-aging agent, accelerator, zinc oxide, and stearic acid and mixing to obtain EPDM rubber compound;

[0023] Step 2: After blending the EPDM rubber compound prepared in Step 1 with ethylene-vinyl acetate copolymer on an open mill, add sulfur, peroxide, foaming agent, and pass through to obtain a blended rubber ;

[0024] Step 3: After the blended rubber prepared in Step 2 was parked for 24 hours, the curing time and foaming time were measured with a vulcanizer, and molded and foamed with a flat vulcanizer. Porous elastomer.

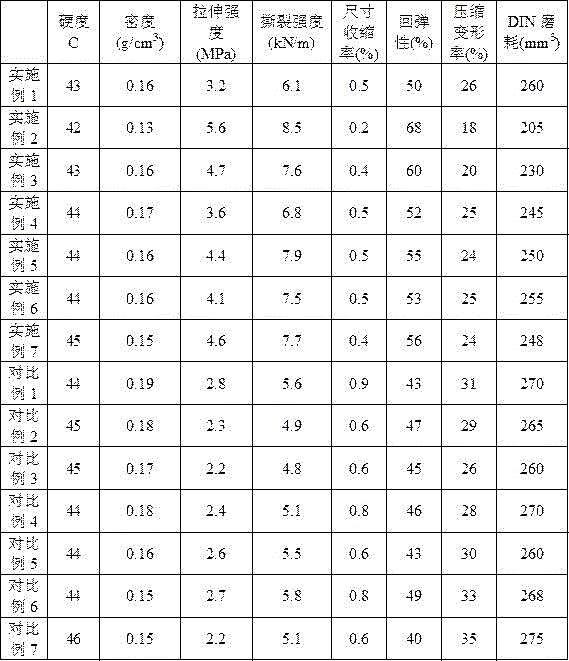

[0025] The prepared microcellular elastomer with high damping performance was subjected to the following performance tests.

[0026] (1) Tensile properties:

[0027] According to the GB / T528-200...

Embodiment 1

[0042] Mix 55 parts of EPDM rubber, 10 parts of 13 μm talc powder, and 5 parts of 18 μm calcium carbonate on an open mill for 20 minutes, add 2 parts of anti-aging agent 264, 3 parts of anti-aging agent RD, 5 parts of zinc oxide, and 3 parts of hard Fatty acid mixing to obtain EPDM rubber compound; blend it with 45 parts of ethylene-vinyl acetate copolymer on an open mill, add 0.5 parts of accelerator DM, 0.5 parts of accelerator CZ, and 3 parts of sulfur , 0.5 parts of dicumyl peroxide, 8 parts of azodicarbonamide, Botong, parked for 24 hours, measured the positive vulcanization time and foaming time with a vulcanizer, and then used a flat vulcanization machine to obtain a microcellular elastomer. The vulcanization temperature is 160°C. The preparation process is as figure 1 shown. The detailed properties of the microcellular elastomer are listed in Table 1.

Embodiment 2

[0044] Repeat the method of embodiment 1 by each component content of appointment, but adopt and contain 10 parts of 18 μ m talcum powders and 10 parts of 18 μ m calcium carbonates in formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com