Noise damping composition

A damping and composition technology, applied in the field of noise damping products, can solve problems such as increasing weight, and achieve the effects of low cost, excellent vibration damping performance, and excellent noise suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

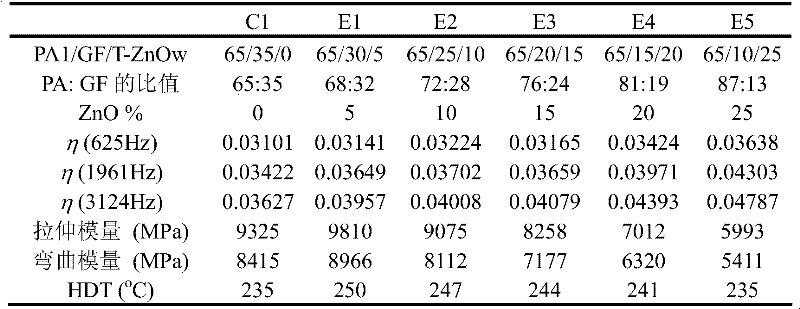

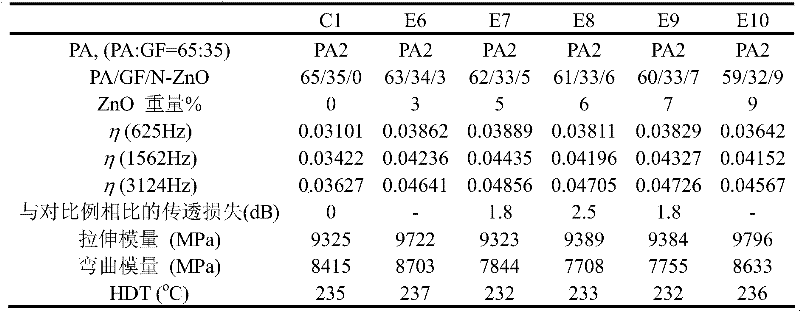

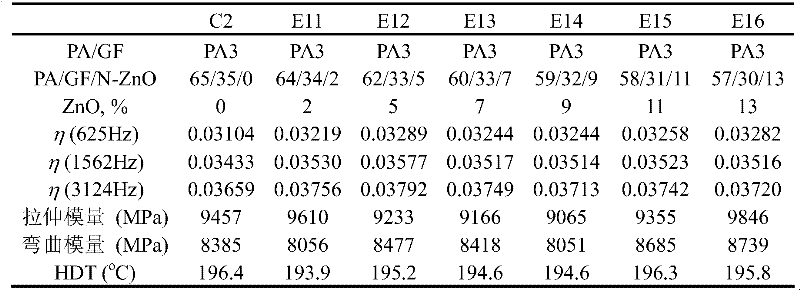

[0094] The abbreviation "E" means "Example", "C" means "Comparative Example", followed by a number indicating in which example the composition was prepared. All examples and comparative examples were prepared and tested in a similar manner. Percentages are by weight unless otherwise indicated.

[0095] Material

[0096] PA1: polyamide 66 resin, produced by DuPont, trade name 101LNC010.

[0097] PA2: polyamide 66, which contains 35% by weight of reinforced glass fibers, produced by DuPont under the trade name 70G35BK267.

[0098] PA3: polyamide 6, which contains 35% by weight of reinforced glass fibers, produced by DuPont under the trade name 73G35BK262.

[0099] N-ZnO: short for nano-zinc oxide, with an average particle size of about 30 nm, surface-modified with 2 wt% KH570; purchased from Hangzhou Wanjing New Material Co., Ltd., China. KH570 is a silane coupling agent, 3-(methacryloyloxy)propyltrimethoxysilane (cas number 2530-85-0).

[0100]T-ZnOw: Abbreviation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com