Noise damping thermoplastic composition

A thermoplastic composition, damping technology, used in the field of noise damping products, noise components, can solve problems such as obstruction, insufficient rigidity, modulus strength or high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

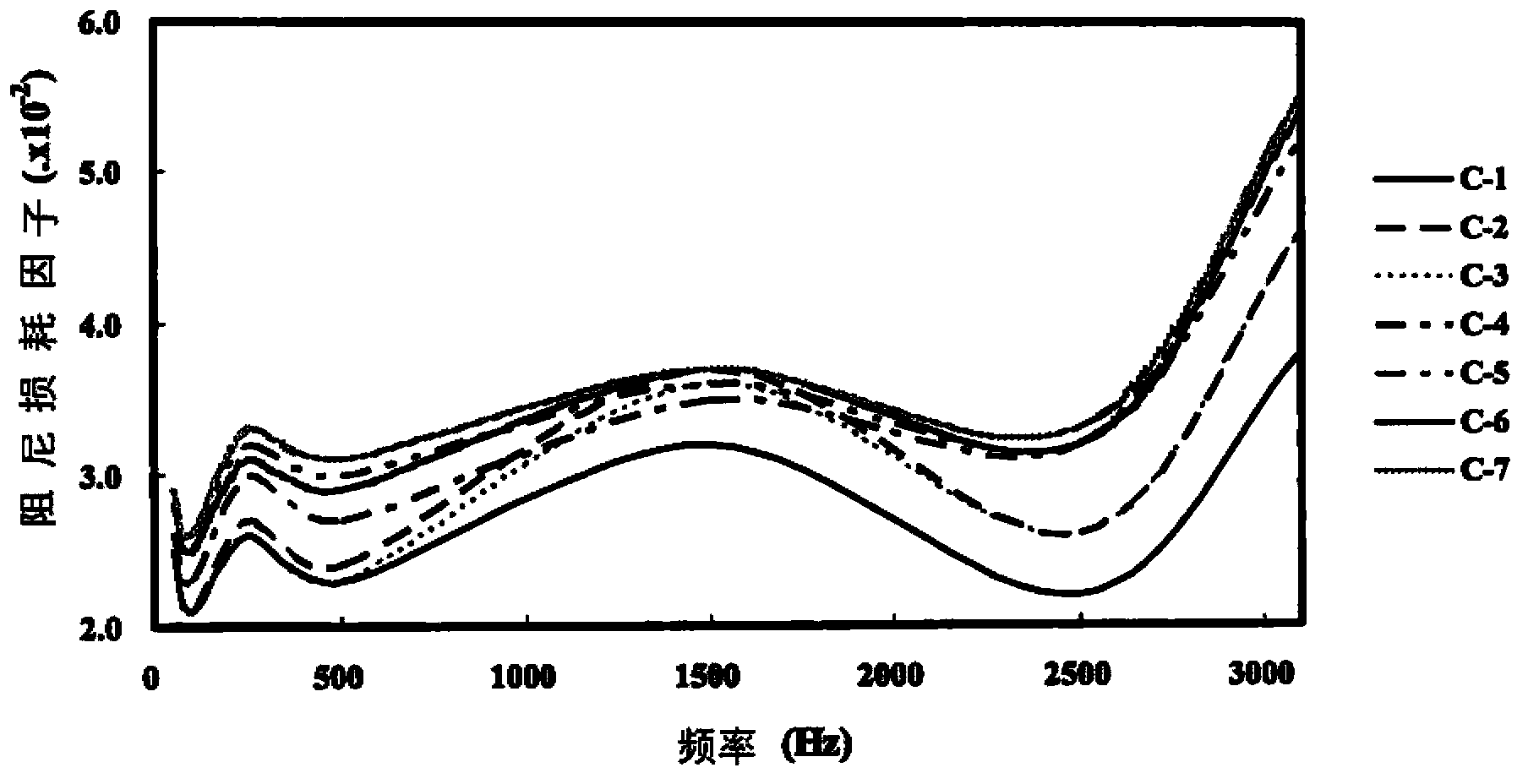

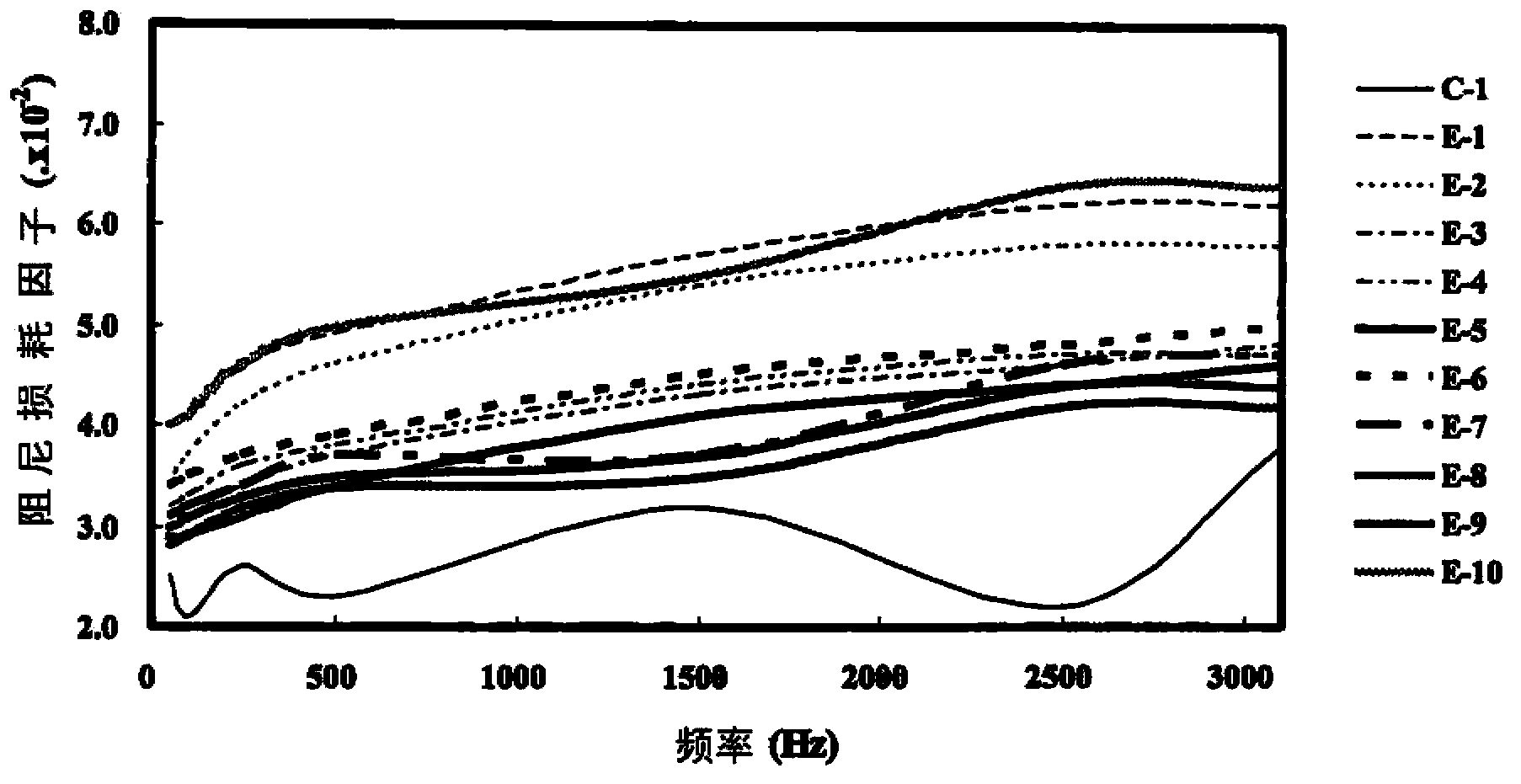

[0118] The abbreviation "E" means "Example", "C" means "Comparative Example", followed by a number indicating in which example the composition was prepared. All examples and comparative examples were prepared and tested in a similar manner. Percentages are by weight unless otherwise indicated.

[0119] Material

[0120] (a) PA / GF: manufactured by DuPont Co. under the trade name Polyamide 6,6 of PLS95G35 containing 35% by weight of glass fiber reinforcement. The general processing temperature and density of its melt extrusion are 280-300°C and 1.42g / cm 3 .

[0121] (b) SEBS-g-MA: produced by Kraton Polymer, USA, trade name FG1901G. FG1901G is a transparent linear ternary block copolymer based on styrene and ethylene / butylene, with a polystyrene content of 30%, modified with about 1.4 wt% ~ 2.0 wt% maleic anhydride. Its MFI and density are 14-28g / 10min (at 230°C and 5Kg load) and 0.91g / cm respectively 3 . in the melt mix For FG1901G, the maximum processing temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com