Secondary balancer of vertical engine of outboard motor

a technology of vertical engine and balancer, which is applied in the direction of propulsive elements, marine propulsion, vessel construction, etc., can solve the problems of increased number of assembling steps, complicated structure of the driving system of the balancer, and easy vibration of the four-stroke cycle engine, so as to improve the assembling work, improve the effect of eliminating vibration, and ensure the effect of assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

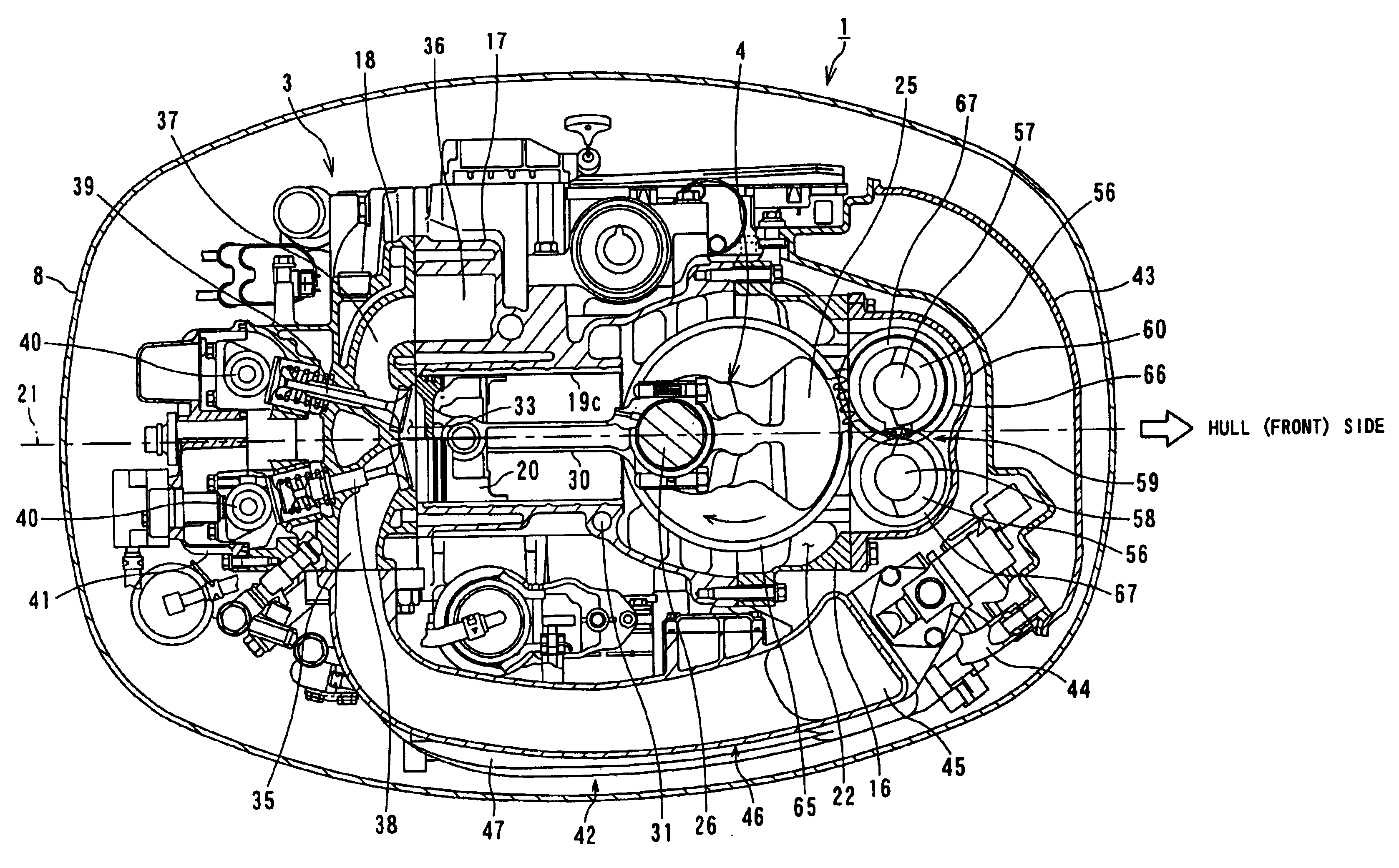

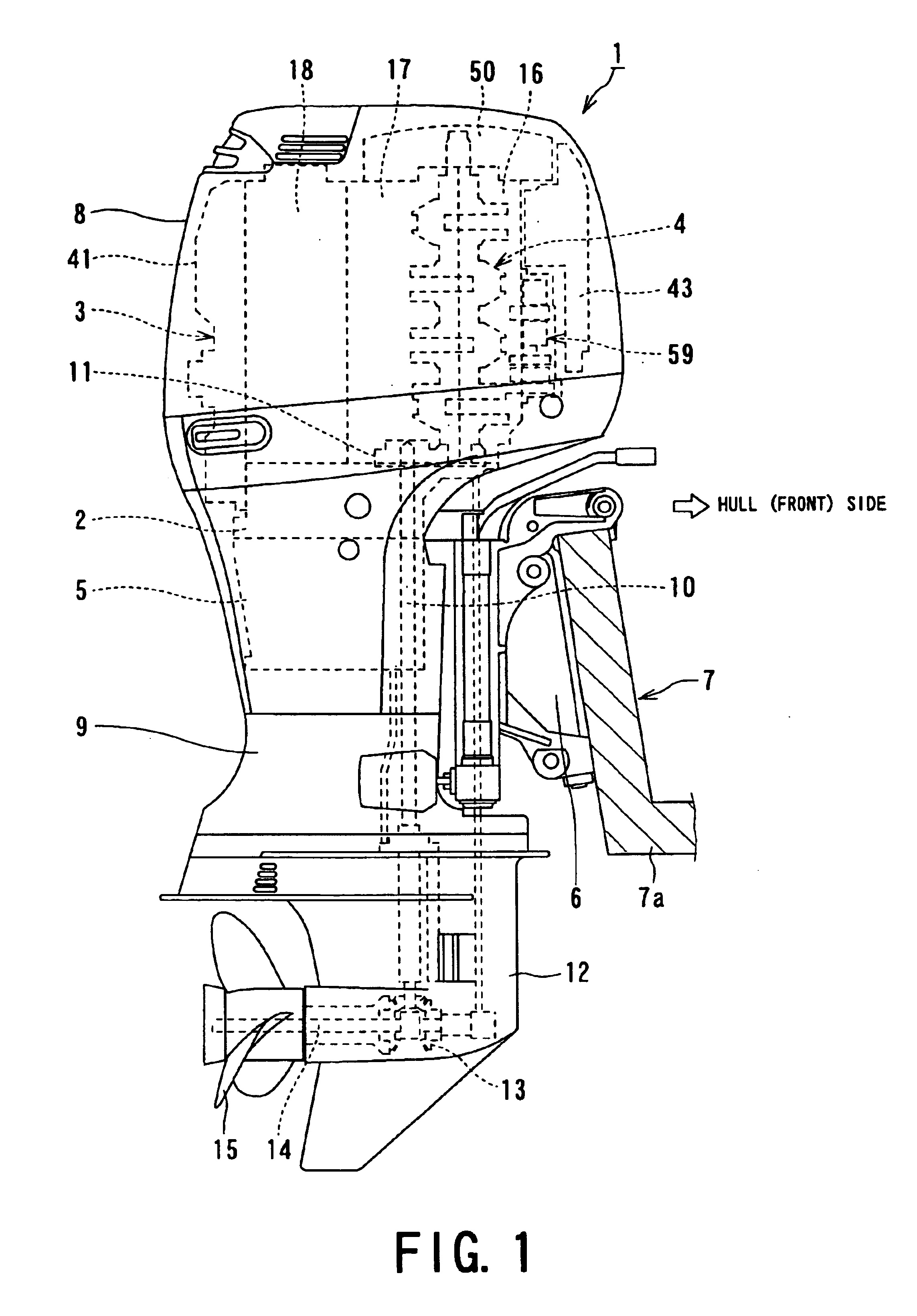

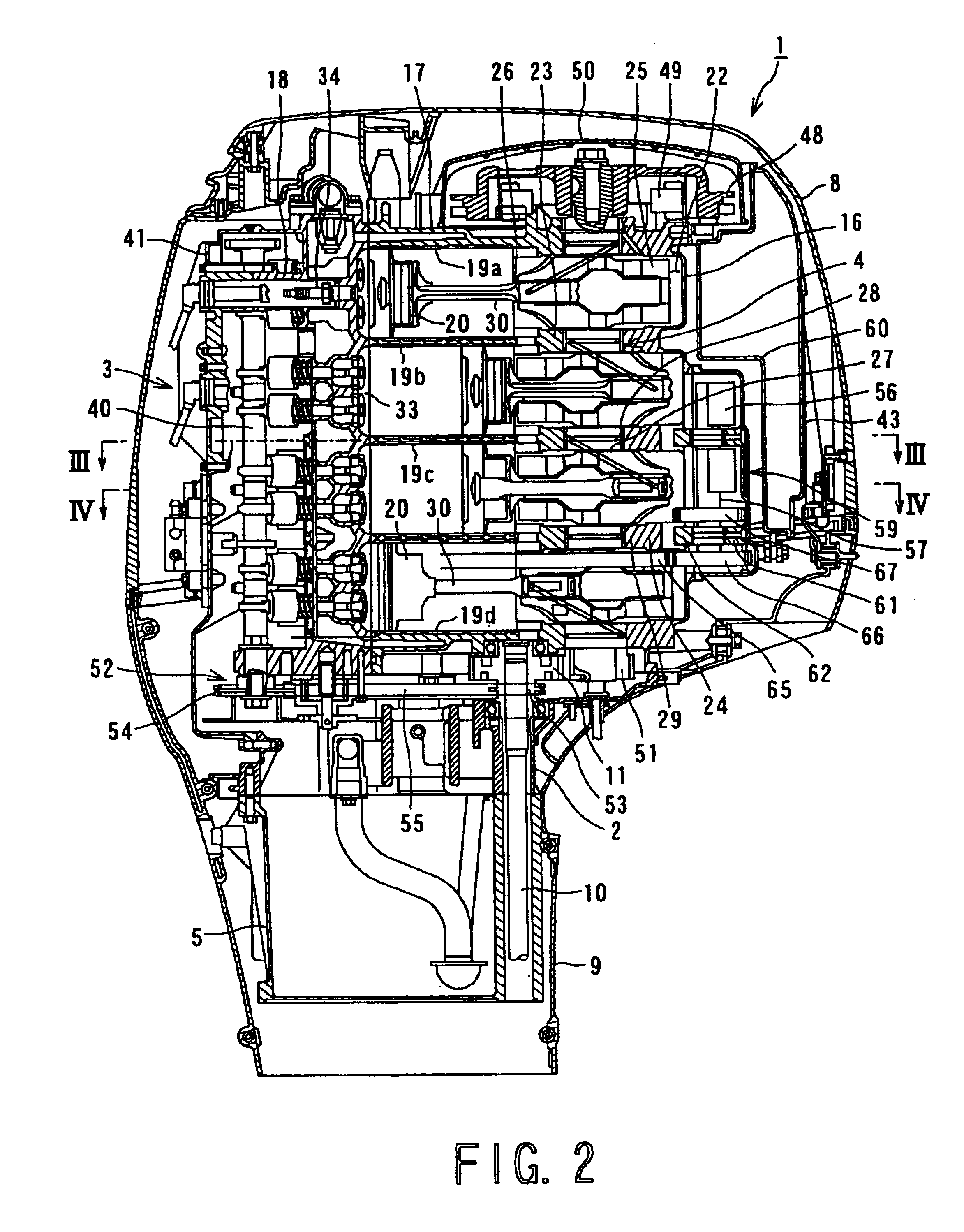

With reference to FIG. 1 illustrating the outboard motor mounted with a vertical in-line engine (vertical type engine) to which the present invention is applied, the outboard motor 1 is provided with an engine holder 2 and an engine 3 is mounted to an upper portion, in the illustrated state, of the engine holder 2. The engine 3 is a vertical type engine in which a crankshaft 4 is placed so as to extend in the vertical, i.e., perpendicular, direction.

An oil pan 5 is disposed below the engine holder 2. In addition, the outboard motor 1 has a clamp bracket 6 secured thereto, through which the outboard motor 1 is mounted to a transom 7a of a hull 7 of a boat to which the outboard motor is mounted. The engine 3 of the outboard motor 1 is surrounded by an engine cover, i.e., cowling 8.

A drive shaft housing 9, which is placed so as to cover the periphery and bottom of the oil pan 5, and a drive shaft 10 extends substantially vertically through the engine holder 2, the oil pan 5 and the dri...

second embodiment

FIG. 5, which shows the present invention, is a side view illustrating the crankshaft 101 and the secondary balancer 102. FIG. 6 is a side view of the crankshaft 101 and the secondary balancer 102, viewed from a direction “VI” in FIG. 5.

In the first embodiment of the present invention, the balancer shafts 57, 58 are driven by the balancer drive gear 65 of the crank-web 25, whereas in the second embodiment of the present invention, the crankshaft 101 is provided at its lower end with a balancer drive sprocket 103, one of the balancer shafts 104, 105 is provided at its lower end with a balancer driven sprocket 106, and a single endless balancer chain 107 is disposed so as to extend between these sprockets 103, 106. Balancer shaft gears 108 are provided on the respective balancer shafts 104, 105 in an operative connection to each other and received in a balancer shaft housing 109. A tension device 110 is also disposed so as to maintain a proper tension of the balancer chain 107.

The ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com