Vibration damping material composition

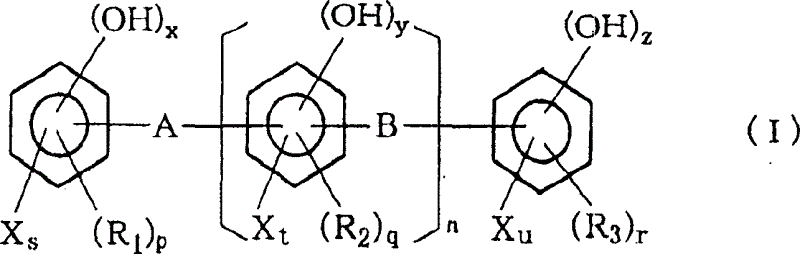

A vibration damping and composition technology, applied in the field of vibration damping material composition, can solve the problems of reduced reagent/polymer interaction, narrow usable temperature range, interaction dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

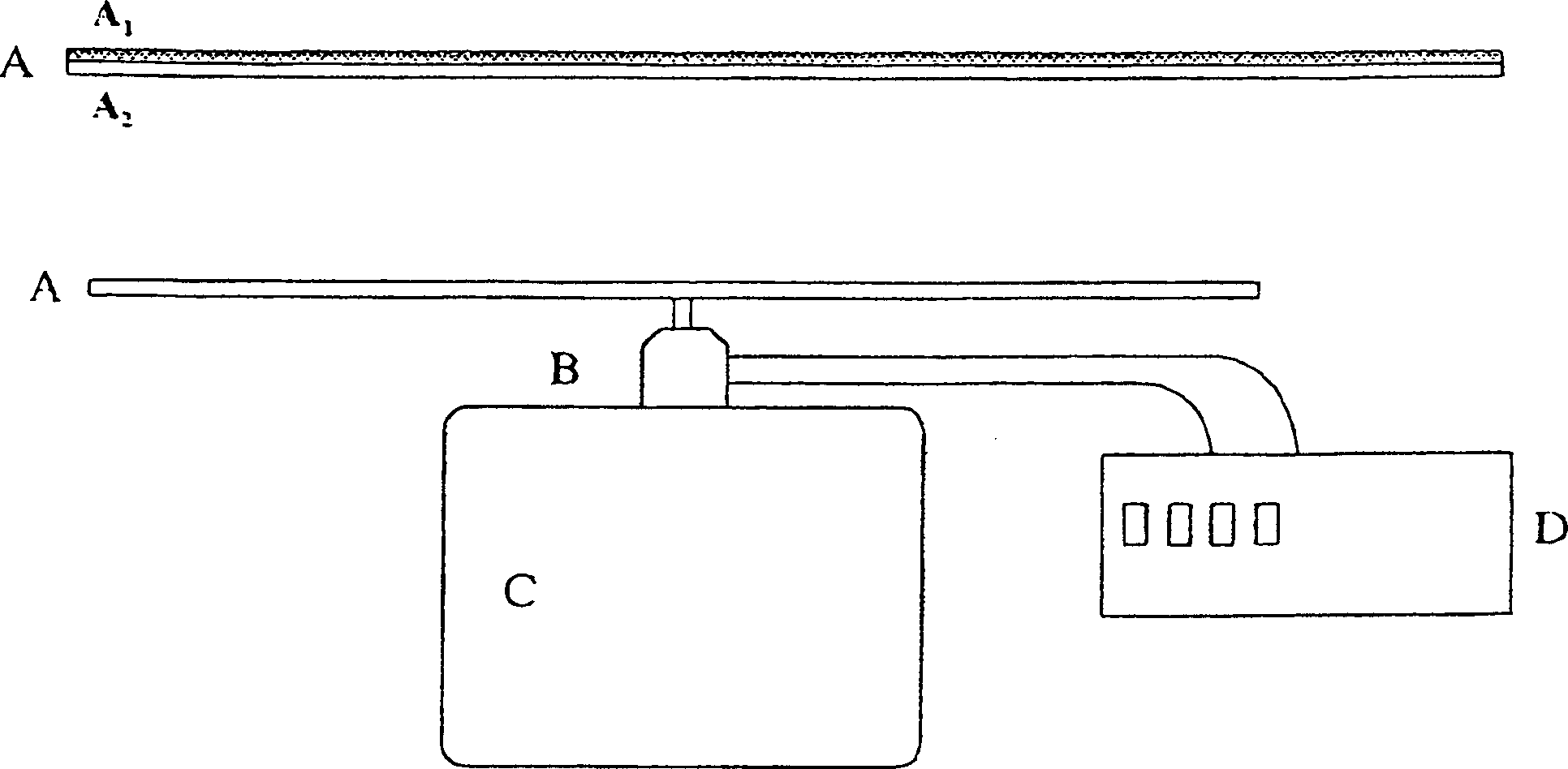

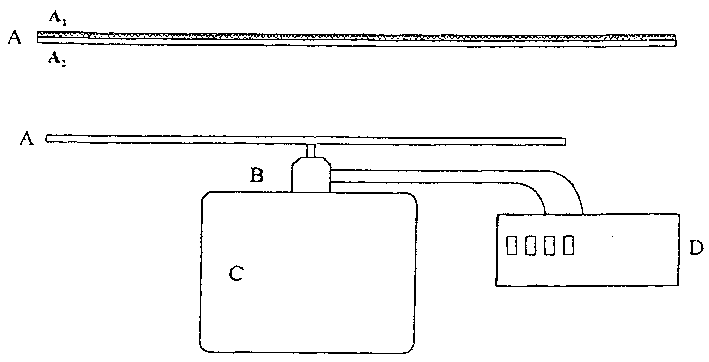

[0132] For each of the vibration damping material compositions prepared in Examples 1-6, wherein 100 parts by weight of acrylic rubber was incorporated as an organic polymer matrix material (hereinafter referred to as a polymer matrix) into the phenol-based compounds shown in Table 1, they were used as The vibration damping agent, the blending amount is also given in Table 1. At 200℃ and 200kgf / m 2 Each mixture was hot-pressed for 20 minutes to form a 1 mm thick sheet-like vibration damping material composition.

[0133] The maximum loss tangent (tan δ) and the temperature range in which tan δ remains greater than 1 were measured according to the above method. The results are shown in Table 1.

[0134] Example

1

2

3

4

5

6

polymer matrix

acrylic rubber 注1)

polylactic acid resin 注2)

100

-

100

-

100

-

100

-

100

-

...

Embodiment 11 to 18

[0153] The vibration damping material compositions in Examples 11 to 18 were prepared, wherein acrylic rubber as an organic polymer matrix, a phenol-based compound, and inorganic and organic fillers were mixed, all of which are given in Table 3, and the mixing ratios are also given in Table 3 out. The evaluation results are shown in Table 3.

[0154] Example

11

12

13

14

15

16

17

18

polymer matrix

acrylic rubber 注1)

100

100

100

100

100

100

100

100

Phenolic compounds

PH1 注2)

PH4 注3)

PH10 注4)

PH9 注5)

PH21 注6)

PH8 注7)

80

80

80

80

80

80

48

30

OF1 注8)

OF2 注9)

32

50

...

Embodiment 19

[0166] A vibration damping material composition was prepared using the same starting materials as in Example 11 and under the same conditions, except that the acrylic rubber was replaced by a mixture of acrylic rubber and polycarbonate 80 / 20. The evaluation results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com