Electromagnetic variable force shock absorber

A shock absorber, electromagnetic technology, applied in vibration suppression adjustment, non-rotation vibration suppression and other directions, can solve the problems of complex structure and assembly, good smoothness, many valves, etc., to achieve improved safety and reliability, fast response, The effect of reducing the risk of driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

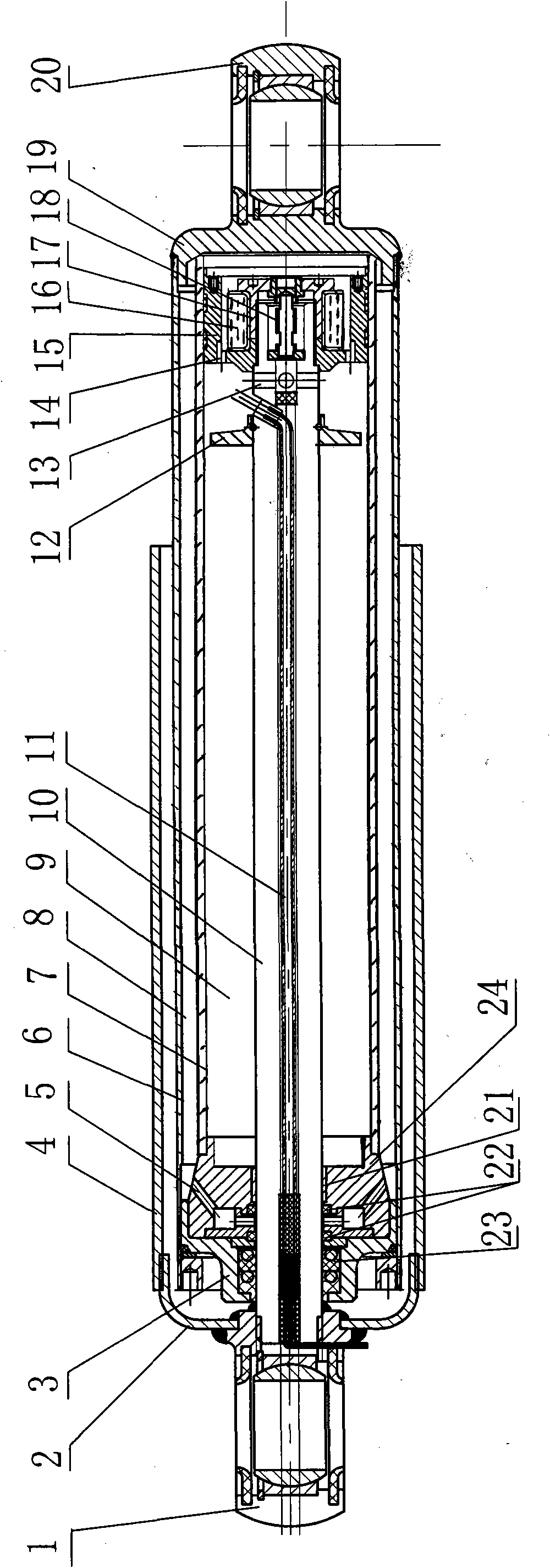

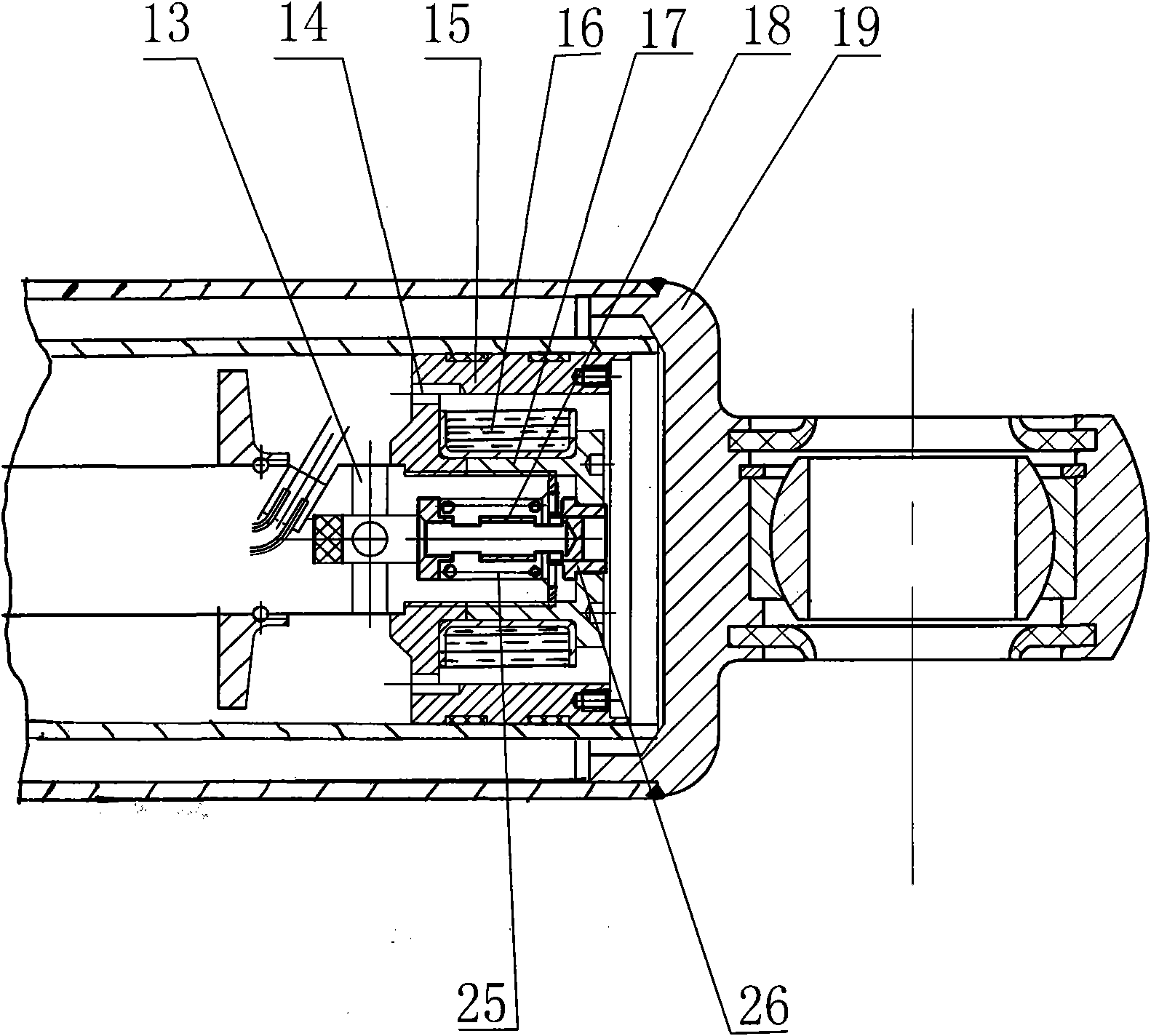

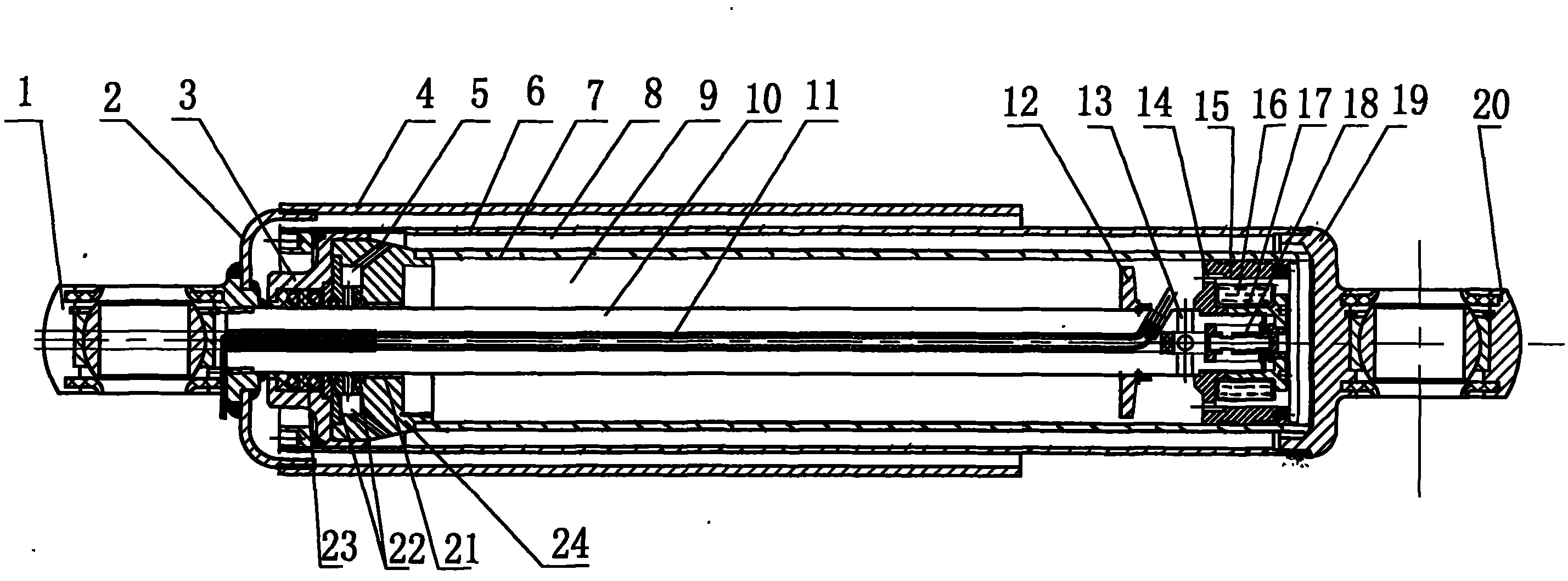

[0009] See figure 1 , 2 , The specific structure of the present invention is as follows: the oil storage cylinder 6 and the working cylinder 7 are welded on the base 19, and an annular oil storage chamber 8 is arranged between the oil storage cylinder 6 and the working cylinder 7. Inside the working cylinder 7 is a working chamber 9 . The upper ends of the oil storage cylinder 6 and the working cylinder 7 are fixedly connected with the oil seal cover 3 and the guide seat 24 respectively. An oil passage 5 is opened on the guide seat 24, and the oil passage 5 communicates with the annular oil storage chamber 8 and the working chamber 9. The piston rod 10 is mounted on the oil seal cover 3 and the guide seat 24 , and oil seals 23 and 22 are arranged between the oil seal cover 3 , the guide seat 24 and the piston rod 10 . The upper end of the piston rod 10 is connected with the upper connecting ring 1 and connected with the dust cover 4 through the welding cap 2 . The lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com