Particle separate device

A divider and divider technology, applied in the direction of spaced quantitative sowing machinery, planter parts, etc., can solve the problems of seed waste, inaccurate seeding quantity, and inability to adapt to various crop seeding problems, such as particle dividers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

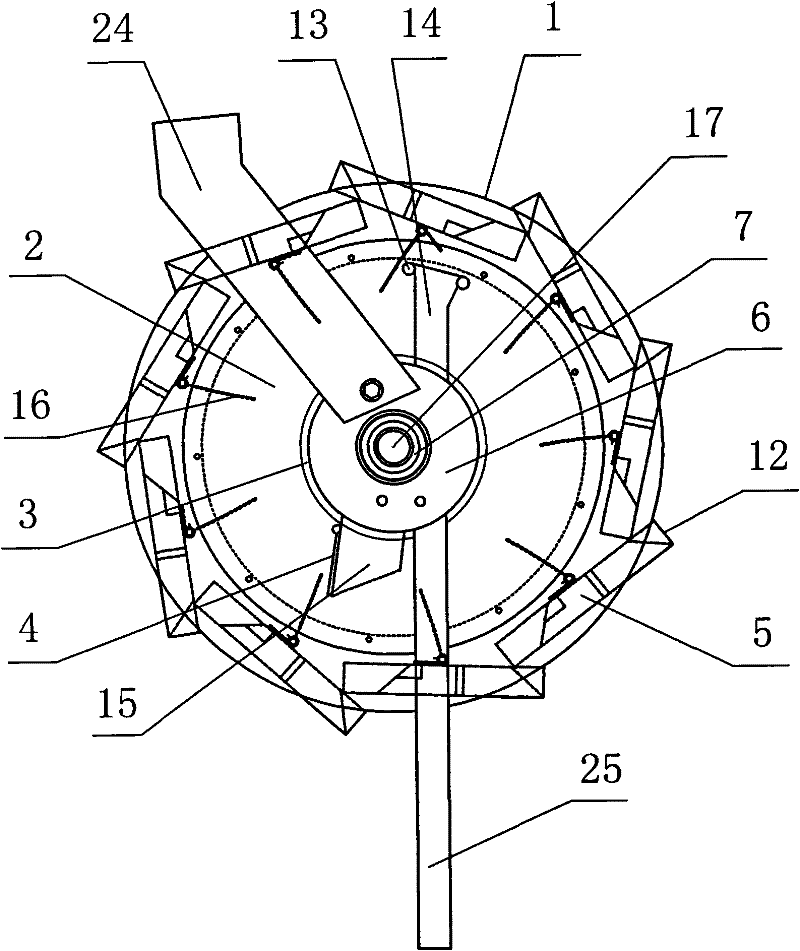

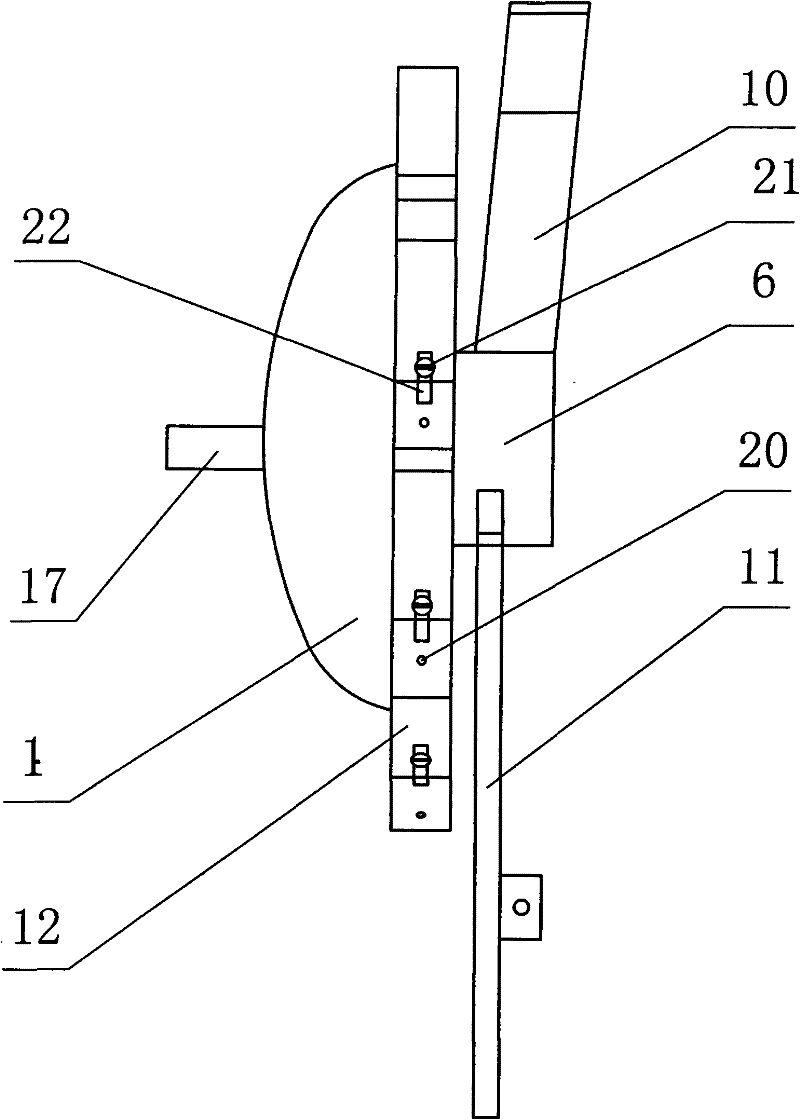

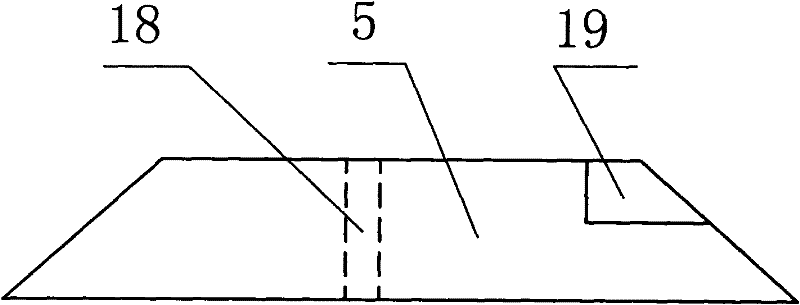

[0023] The particle divider is composed of a divider housing 1, a sealing cover plate 2, a classification adjustment plunger 5, and a guide diverter 6. The seal cover plate 2 is fastened on the divider housing 1 by screws, and the guide divider Cover plate sealing ring 3 is housed between 6 and sealing cover plate 2. The plunger installation chute 12 of the cylinder is made on the splitter housing 1, the upper part of the plunger installation chute 12 is made with a positioning groove 22, and the positioning screw 21 is housed on the positioning groove 22, and one side of the positioning groove 22 is made with a Lookout hole 20. One end of plunger installation chute 12 is equipped with control valve 8 and control rod 16, and return spring 9 is housed on control valve 8. The plunger installation chute 12 is equipped with a classification adjustment plunger 5, the two ends of the classification adjustment plunger 5 are made with a seed storage tank 19, the middle part is made w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com