Diaphragm structure used for pulse valve

A technology of pulse valve and diaphragm, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. It can solve the problems of increasing the sealing leakage point of the diaphragm assembly, wear and tear, and the limitation of the use of pulse valves, etc., and achieves a simple structure , Wide range of application fields, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

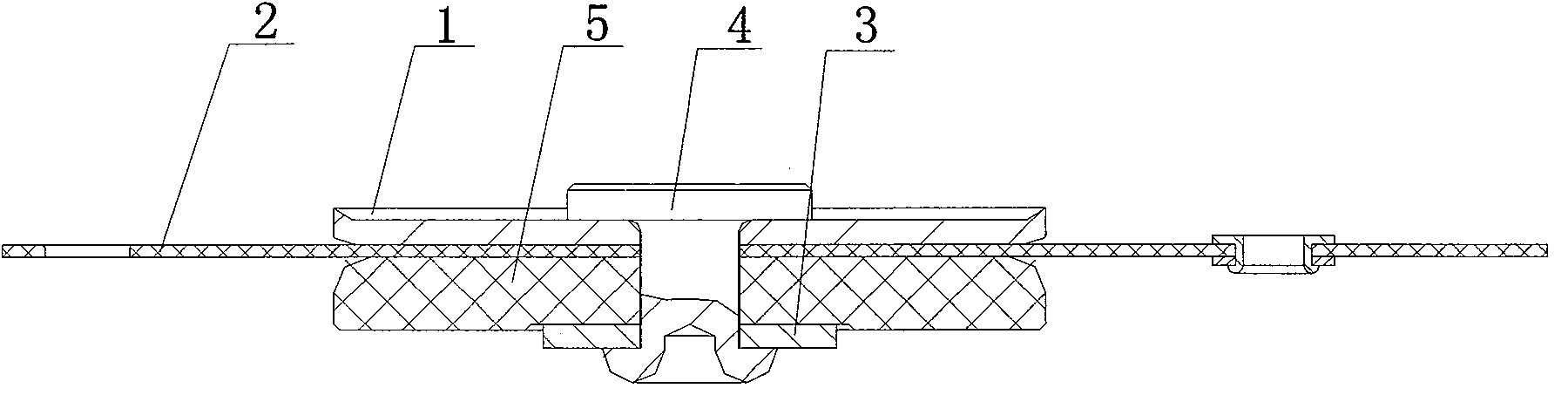

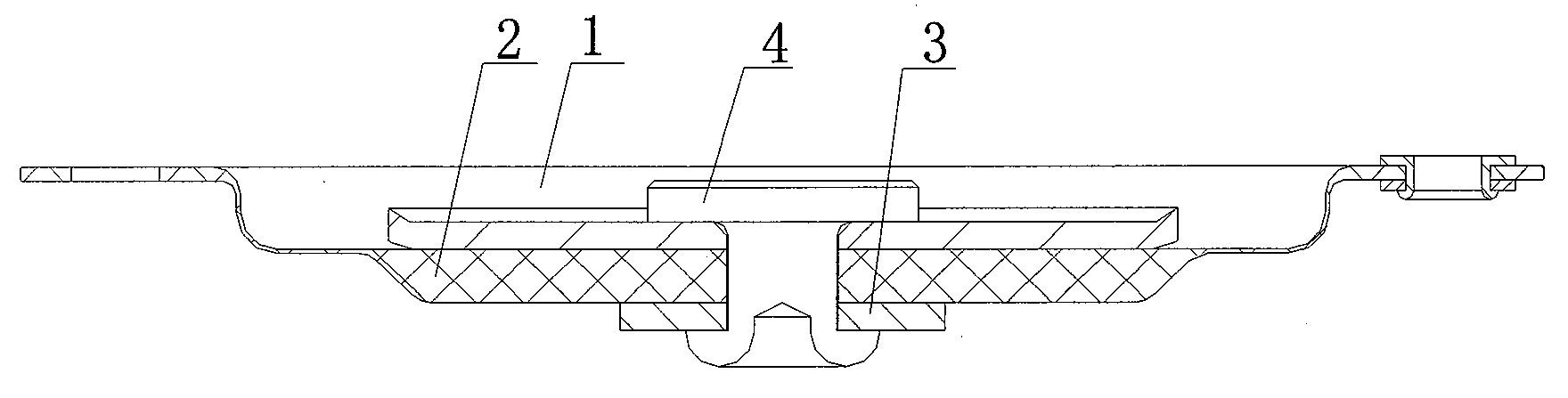

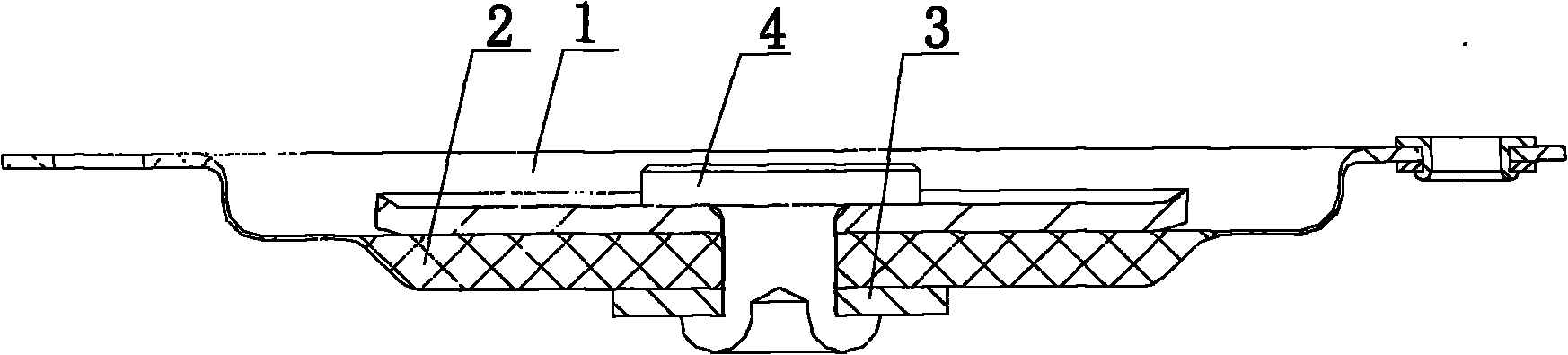

[0013] Such as figure 2 As shown, a diaphragm structure for a pulse valve includes a backing plate 1, a diaphragm 2, and a gasket 3 connected in sequence. The backing plate 1 is disc-shaped, and the front middle of the diaphragm 2 An annular protrusion 20 is provided for sealing, and the back side of the diaphragm 2 is attached to the peripheral wall and front side of the backing plate 1 to form a corrugated cross-section adapted to its stroke.

[0014] The diaphragm 2 is a polytetrafluoroethylene PTFE diaphragm; the backing plate 1, the diaphragm 2 and the gasket 3 are connected by rivets 4, or by threads.

[0015] The center of the diaphragm is used for the sealing of the valve body and seat of the pulse valve. The quality of the valve directly affects the performance of the pulse valve. The membrane assembly of the new structure makes the mechanical properties of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com