Washing process stirring barrel for preparation of barium sulfate

A technology of barium sulfate and mixing barrels, which is applied to mixers with rotating stirring devices, dissolving, mixing machines, etc., can solve the problems of long time consumption and difficulty in fully stirring the slurry, and achieve fast stirring speed, high reliability, Wash evenly and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the specific drawings and embodiments.

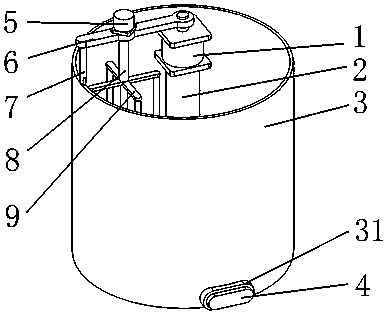

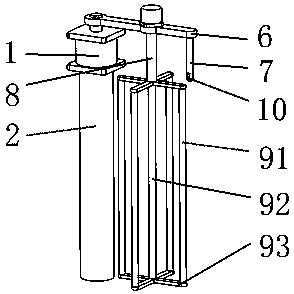

[0014] like Figure 1-2 As shown, the present invention mainly includes a barrel 3, an agitator 9, a second motor 5 for rotating the agitator 9, the bottom end of the barrel 3 has a discharge port 31 for finally discharging the slurry, and the inner center of the barrel 3 A mounting post 2 is fixed at the place, a first motor 1 is mounted on the mounting post 2, the output shaft of the first motor 1 is connected to one end of a rotary rod 6 for mounting the second motor 5, and the other end of the rotary rod 6 is mounted with a The supporting leg 7 of the rotating walking wheel 10, the middle of the rotating rod 6 is provided with a mounting hole and the second motor 5 is installed on this basis, and the output shaft of the second motor 5 is installed with a stirrer 9 through a double-ended threaded rod 8, and the stirring The device 9 includes four stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com