Antistatic drum cloth for mine

An electrostatic cylinder, mining technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problem of unsuitable weaving density of mine anti-static cylinder cloth, and achieve the effect of reasonable mechanical properties and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

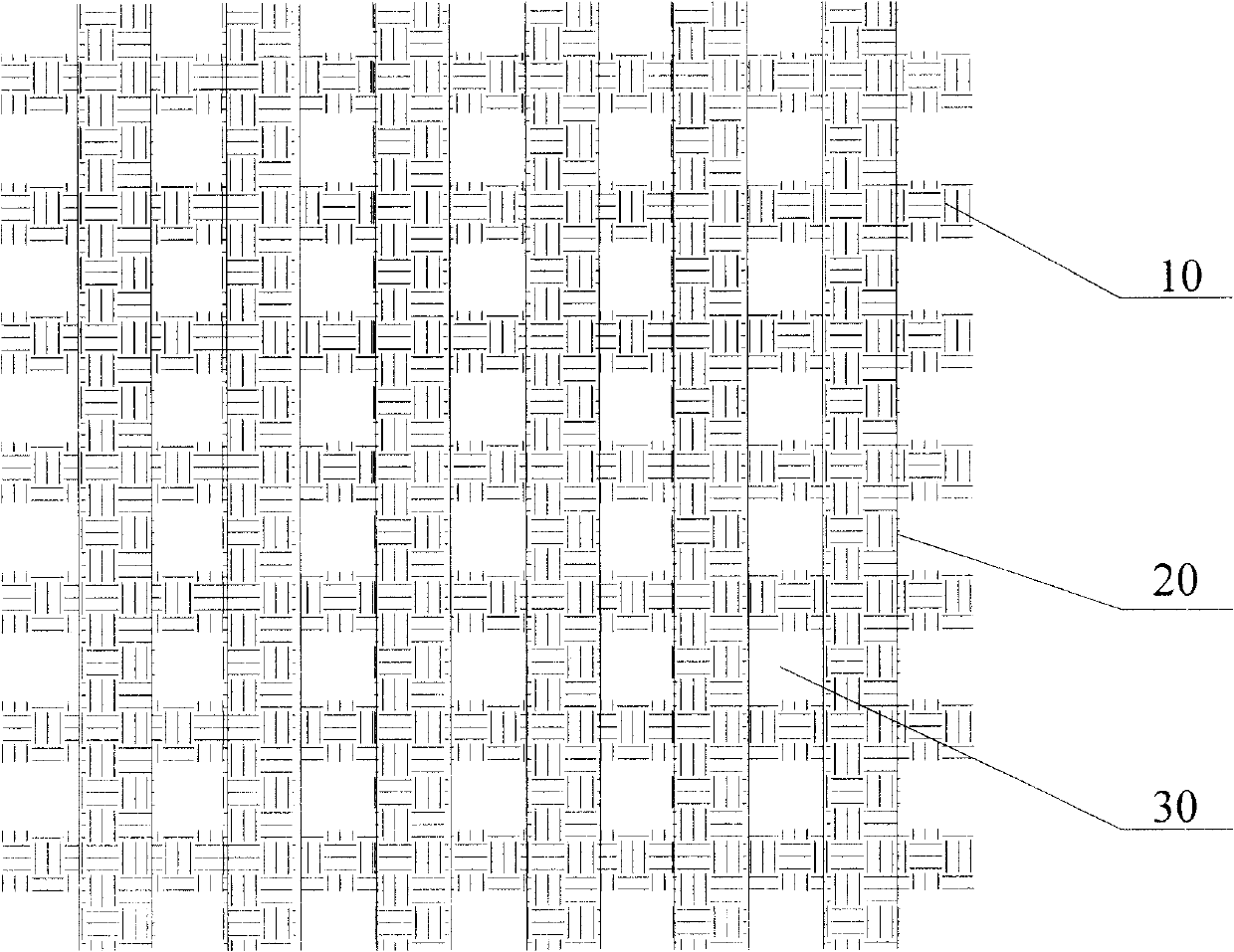

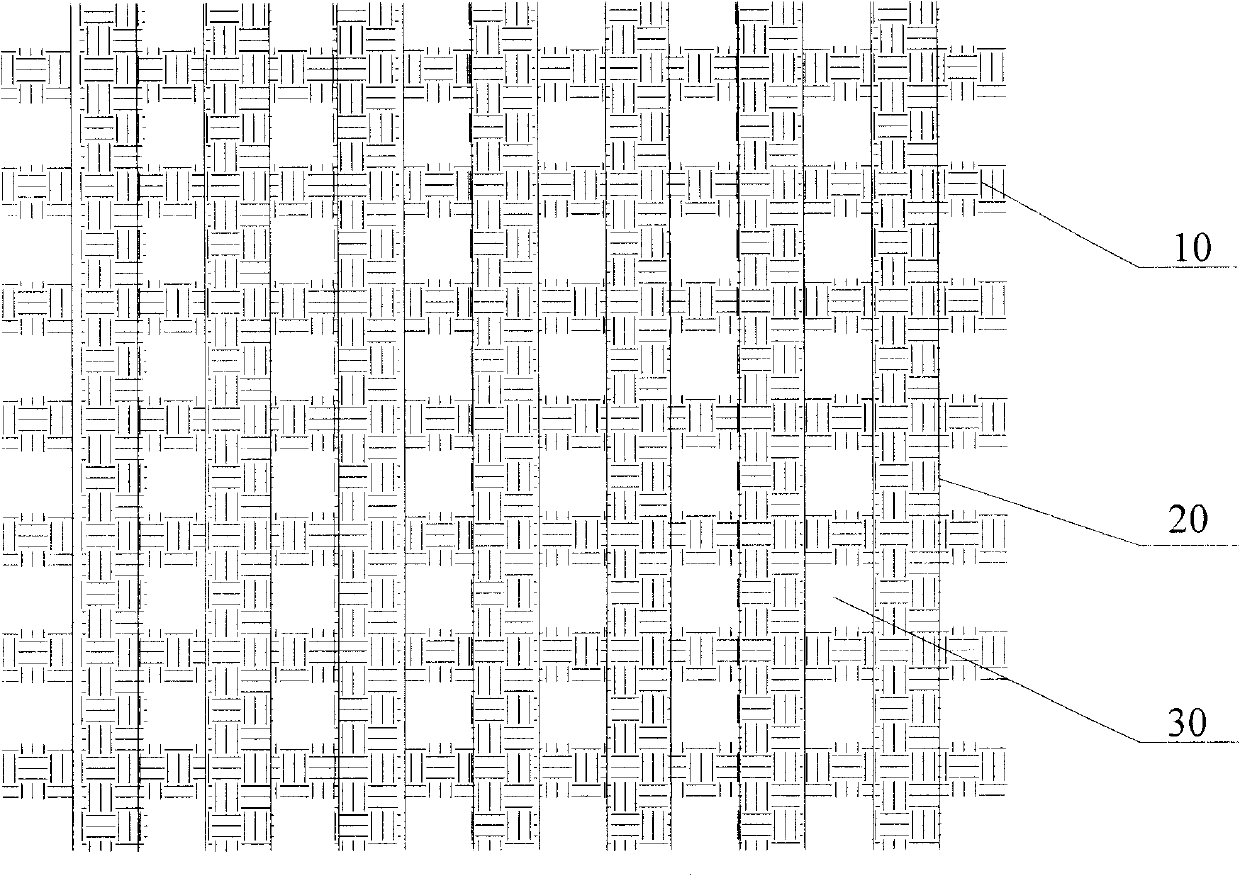

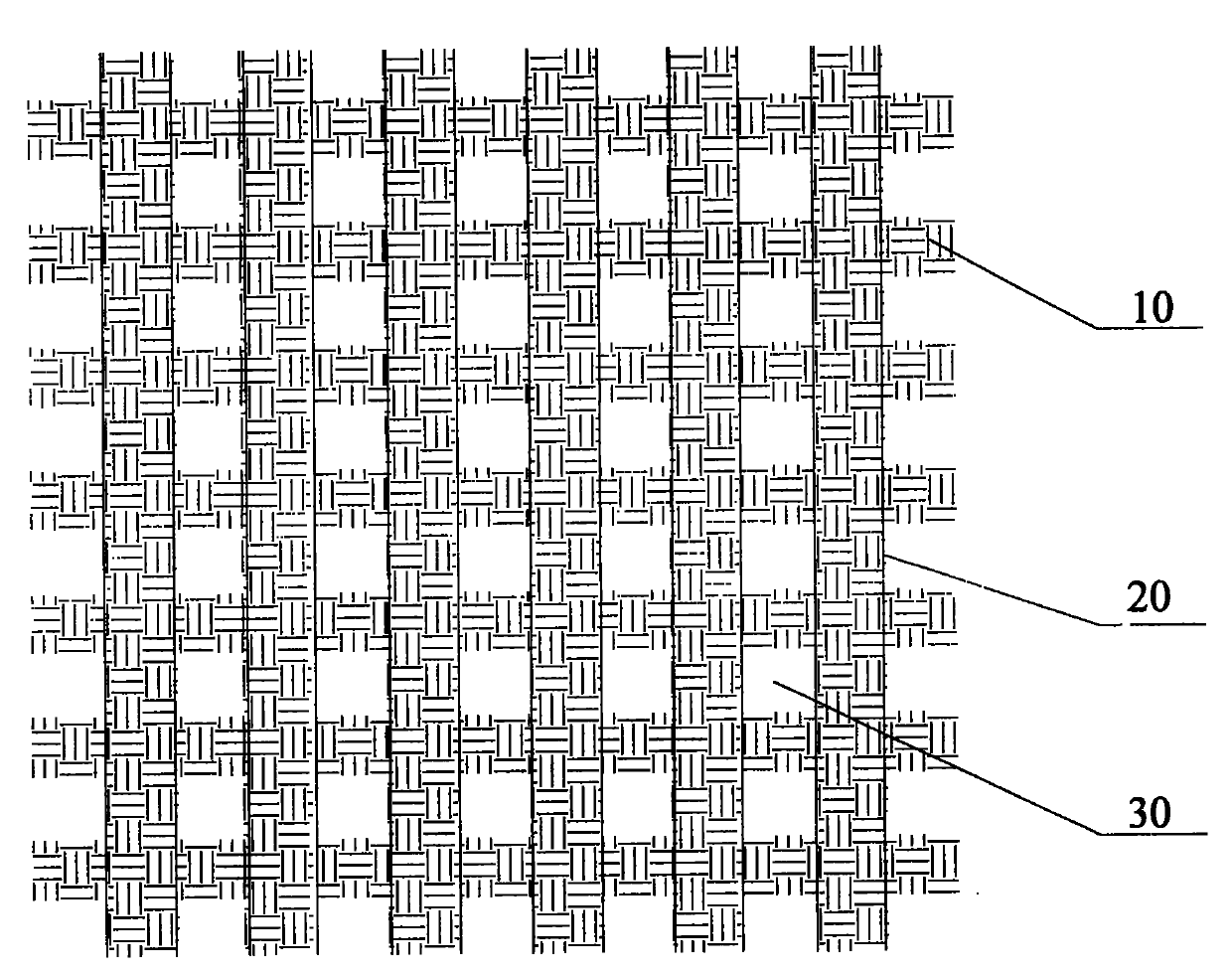

[0021] figure 1 and figure 2 The top view structure of the antistatic cloth for mines according to the embodiment of the present invention is shown. Such as figure 1 and figure 2 As shown, the mine antistatic cloth according to the embodiment of the present invention is formed by interweaving monofilaments in the warp and weft directions, and within a square area of 2.5 cm by 2.5 cm, the number of monofilaments in the warp direction is at least 7 , up to 12; the number of monofilaments in the weft direction is at least 6 and up to 11. For example, the weave density is 7×6 or 12×11. The material and structure of the monofilament 10 in the warp direction and the monofilament 20 in the weft direction are generally the same, so as to be common and easy to manufacture. Of course, different materials and structures can also be con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com