Comprehensive performance test table for water-lubricated dynamic-static pressure radial sliding bearing

A technology of radial sliding and comprehensive performance, applied in the direction of mechanical bearing testing, etc., can solve the problems of single working condition and parameter, single temperature, pressure, no occurrence, etc., to achieve the effect of convenient operation, sensor protection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

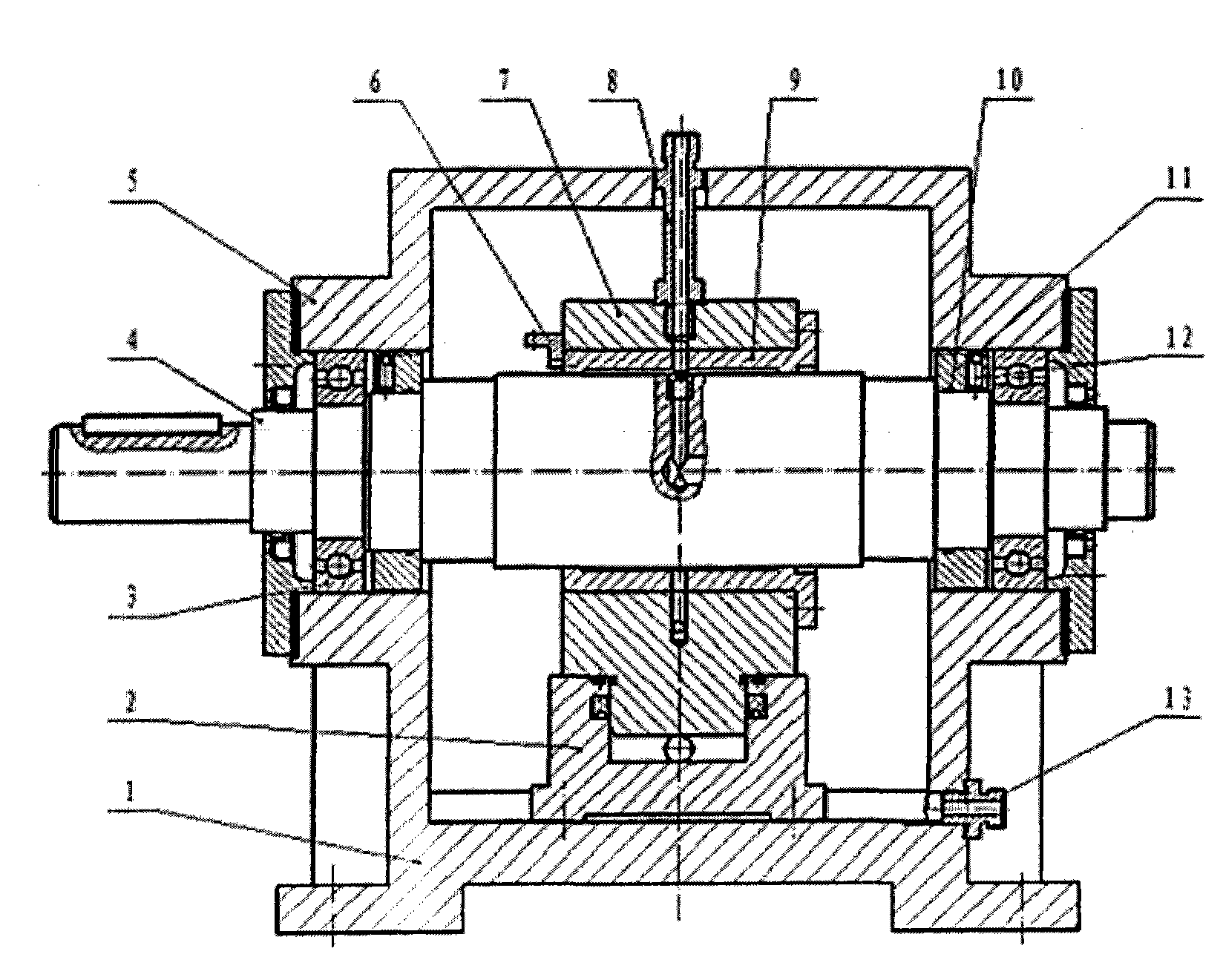

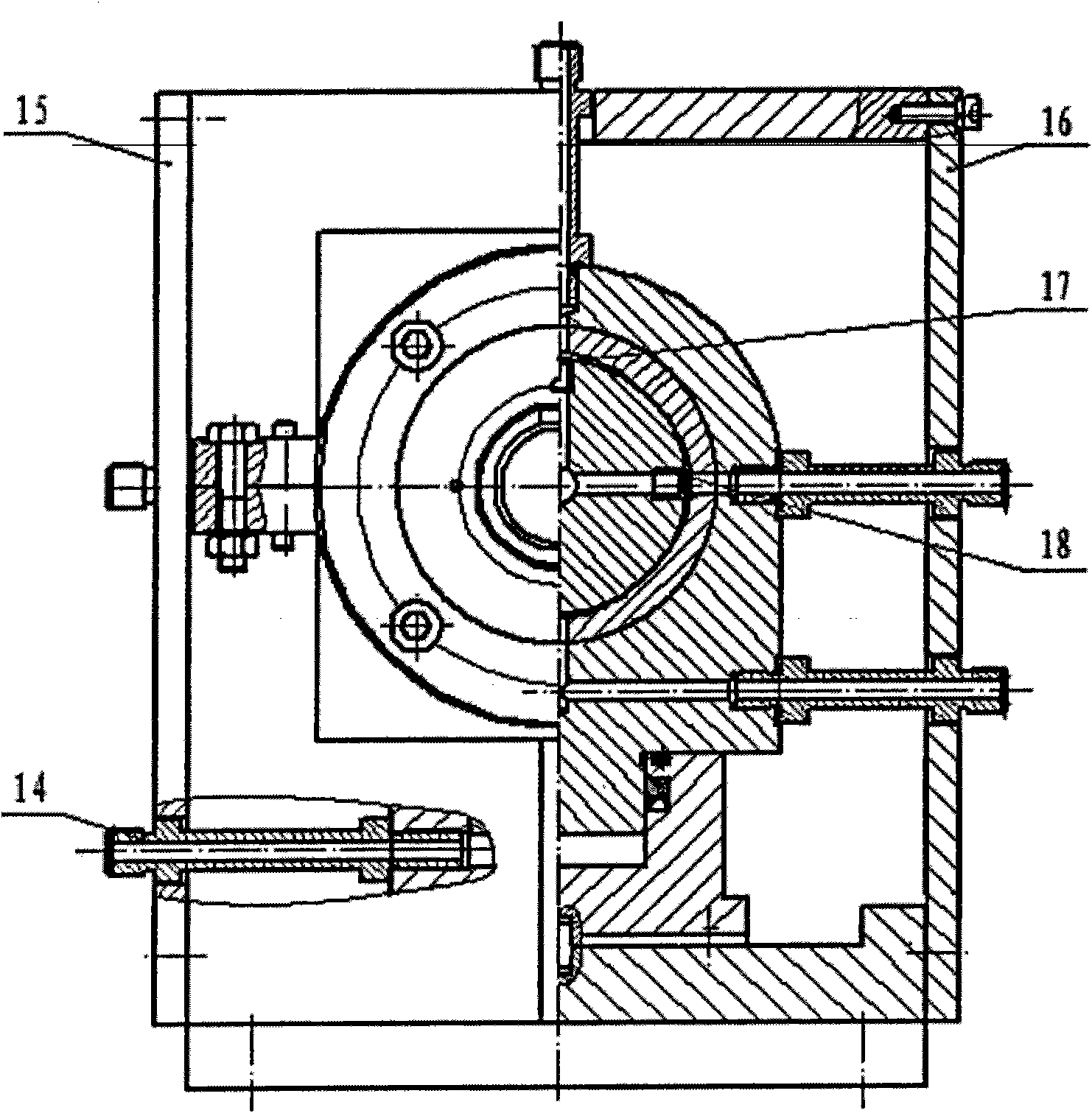

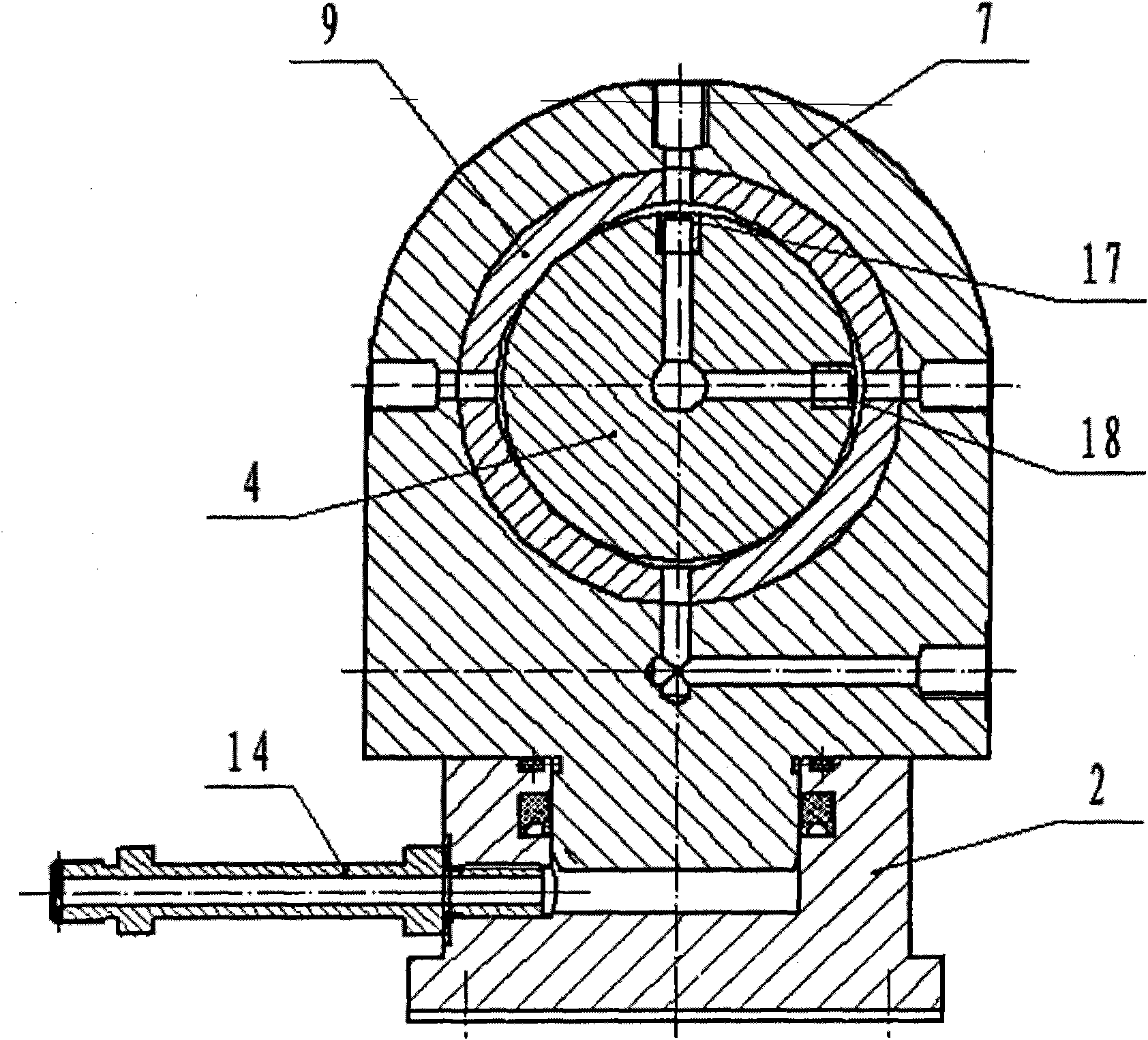

[0018] The design idea of the present invention is: the motor drives the main shaft to run, and the speed of the motor is adjusted by the frequency converter to adjust the different speeds of the shaft, so as to meet the working condition requirements of different linear speeds of the shaft during the test. The central part of the main shaft is supported by a sliding bearing installed in the bearing seat, and the pressure water in the hydraulic system acts on the bearing seat to realize the loading of the system. By changing the width of the sliding bearing and the matching bearing seat, and changing the width-to-diameter ratio of the experimental bearing, the performance test of bearings with different width-to-diameter ratios can be realized. By adjusting the relevant hydraulic components in the hydraulic system to meet the needs of dynamic pressure and static pressure lubrication, during the dynamic pressure test, the hydraulic system lubricates the sliding bearing with no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com