Improved button cell

A button battery and battery assembly technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of reduced battery life, poor contact, deformation of sealing rings, etc., to improve quality stability and increase contact surface pressure. , the effect of large deformation of the sealing ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

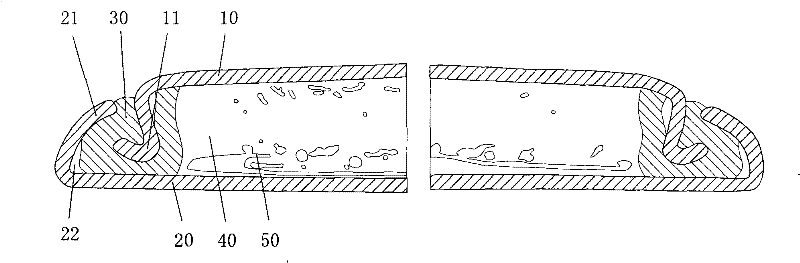

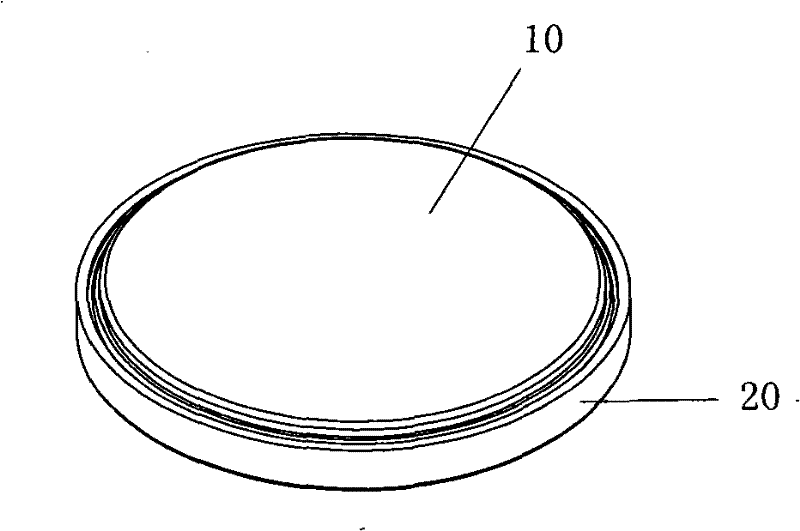

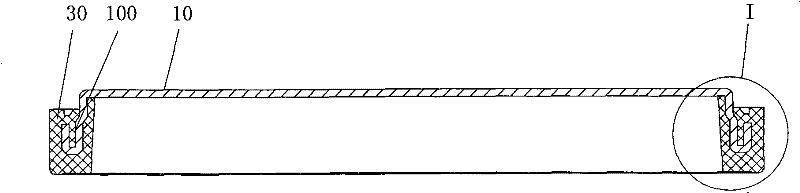

[0021] like figure 2 , 3 , 4, the button battery of the present invention includes an integrated negative electrode cover 100 in which a sealing ring 30 is integrated on the negative electrode cover 10, a positive electrode cover 20 which is insulated and snapped together with the integrated negative electrode cover 100, and is arranged on the positive electrode cover 20 and the integrated negative electrode cover 100. In the battery assembly (not shown in the figure) between the integrated negative electrode cover 100 , an annular groove 31 surrounding the negative electrode cover 10 is provided on the upper side of the seal ring 30 matching the flange of the positive electrode cover 20 . The part of the upper side of the sealing ring 30 outside the annular groove 31 is continuously and closely fitted with the flange of the positive electrode cover.

[0022] In this embodiment, the annular groove 31 is arranged in the middle of the cross section of the sealing ring 30 . In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com