A shock absorber for new energy vehicles

A technology of new energy vehicles and shock absorbers, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of elastic attenuation, unstable shock absorption effect, and reduce the service life of parts, and achieve Avoid elastic attenuation, good shock absorption effect, and improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

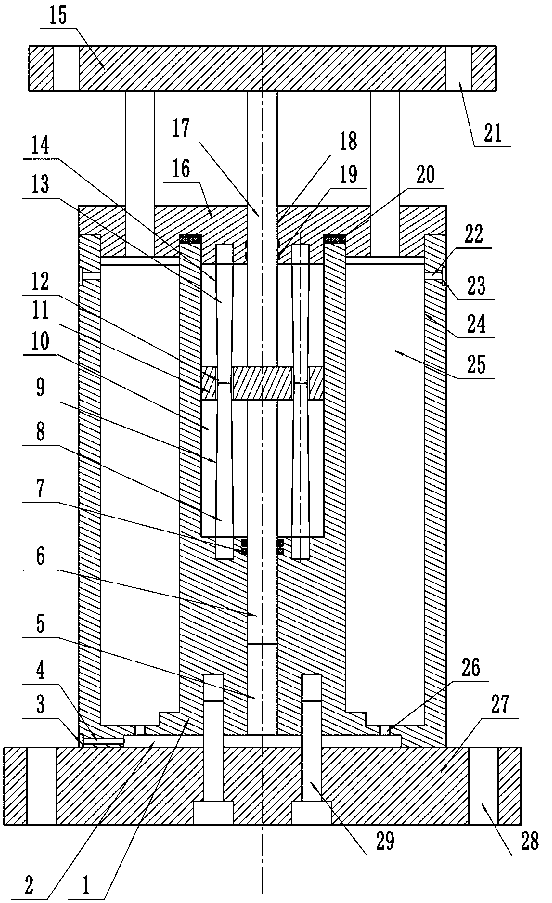

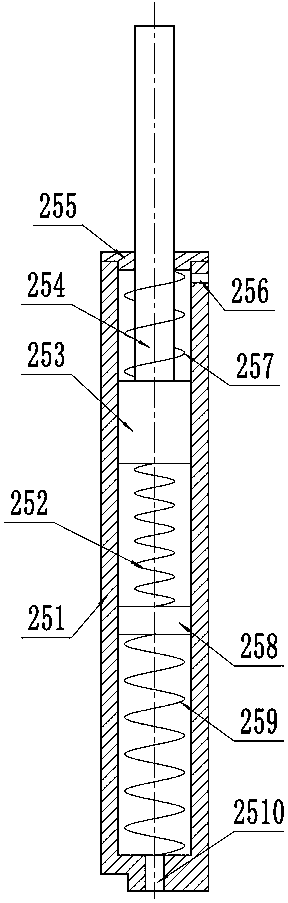

[0020] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a shock absorber for new energy vehicles, including a housing 1, a groove 2, a filter screen-3, a breathing hole-4, a guide hole-5, and a guide post-6 , seal ring one 7, shaft body one 8, cone surface one 9, oil chamber 10, piston 11, communication hole 12, shaft body two 13, cone surface two 14, upper connecting seat 15, top cover 16, guide post two 17. Guide hole 2 18, sealing ring 2 19 and sealing gasket 20; the bottom surface of the housing 1 is provided with a groove 2 in the center; the left side of the groove 2 communicates with the outside air through the breathing hole 1 4; the breathing A filter screen-3 is provided in the opening on the left side of the hole-4; the guide hole-5 is located in the lower center of the housing 1, and the lower opening of the guide hole-5 communicates with the inside of the groove 2. The opening on the upper side of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com