Pipe expanding equipment

A kind of equipment and tube expansion technology, which is applied in the field of tube expansion equipment, can solve the problems that the effective expansion of tube sheets cannot be satisfied, and the simultaneous expansion of multiple pipe fittings on two tube sheets cannot be realized, so as to reduce the cost of expansion joints , Simple structure, high expansion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

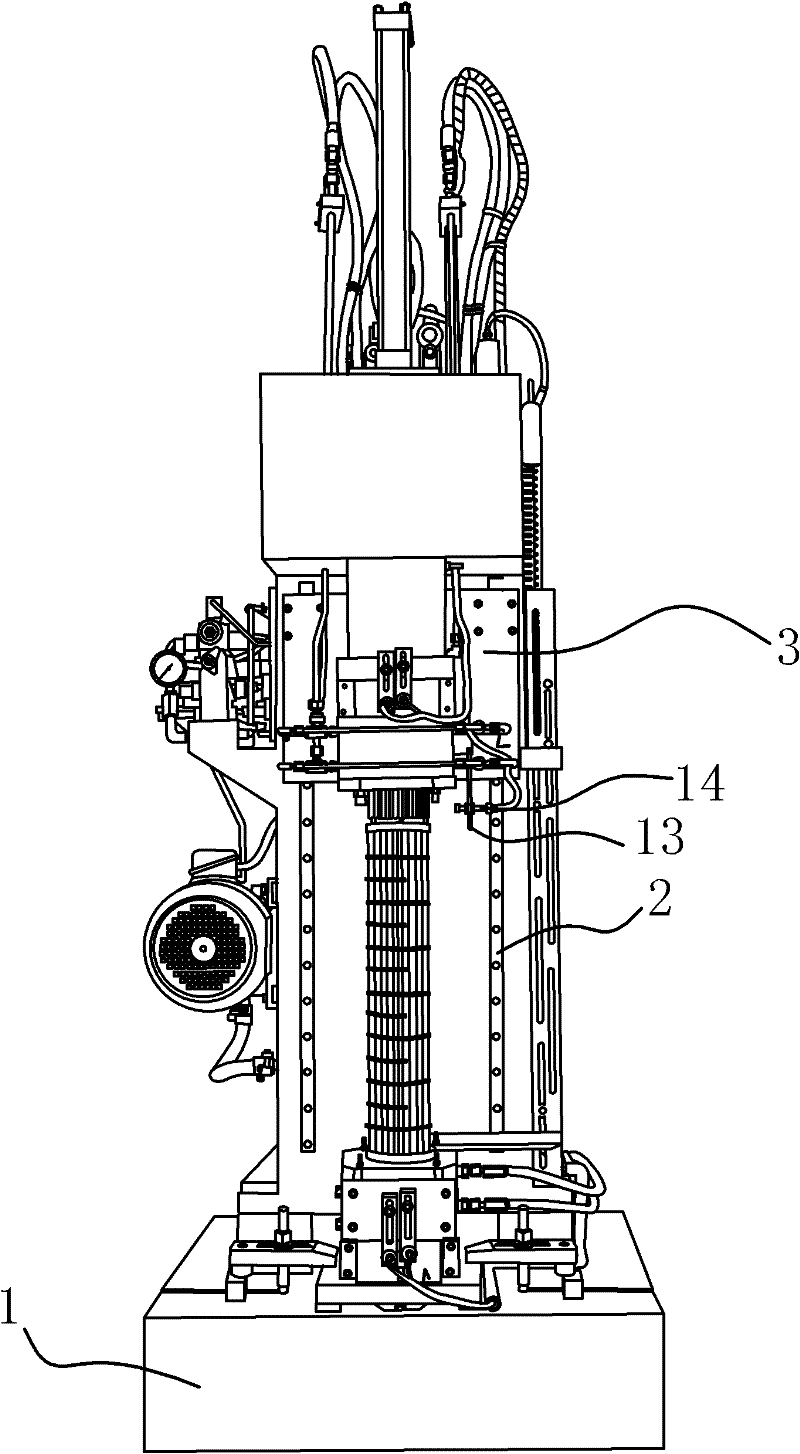

[0042] Such as figure 1 As shown, a tube expansion device is mainly divided into two types: vertical and horizontal. In the first embodiment, the tube expansion device is vertical, including a base 1, on which two The tube expander with the same structure is oppositely arranged, and the lower tube expander is fixed on the machine base 1 . On the machine base 1, a guide rail 2 is provided along the line direction of the two expansion devices. The guide rail 2 is provided with a carriage 3 that can slide along the guide rail 2. plate 3.

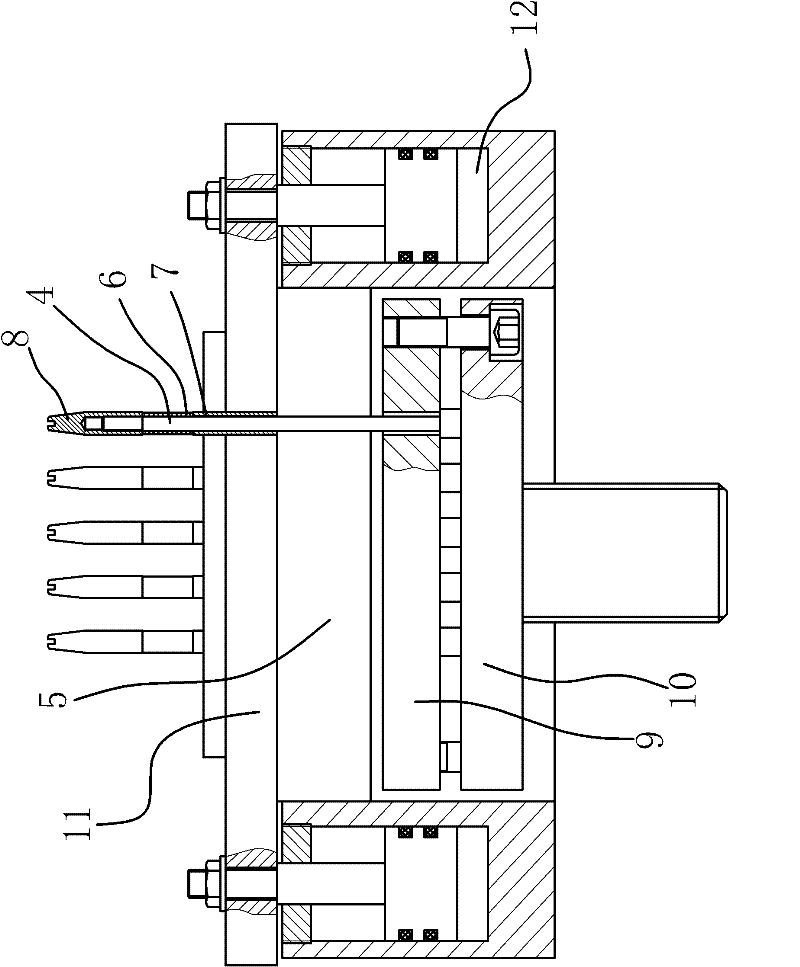

[0043] Such as figure 2 As shown, there are several expansion rods 4 with the same number and one-to-one correspondence on the two expansion devices. The expansion device also includes a support plate 5 and a power mechanism. 5 Clearance fit, one end of the expansion rod 4 protrudes from the support plate 5 and an expansion joint structure is provided at this end, the other end of the expansion rod 4 is connected to the power mechanism on t...

Embodiment 2

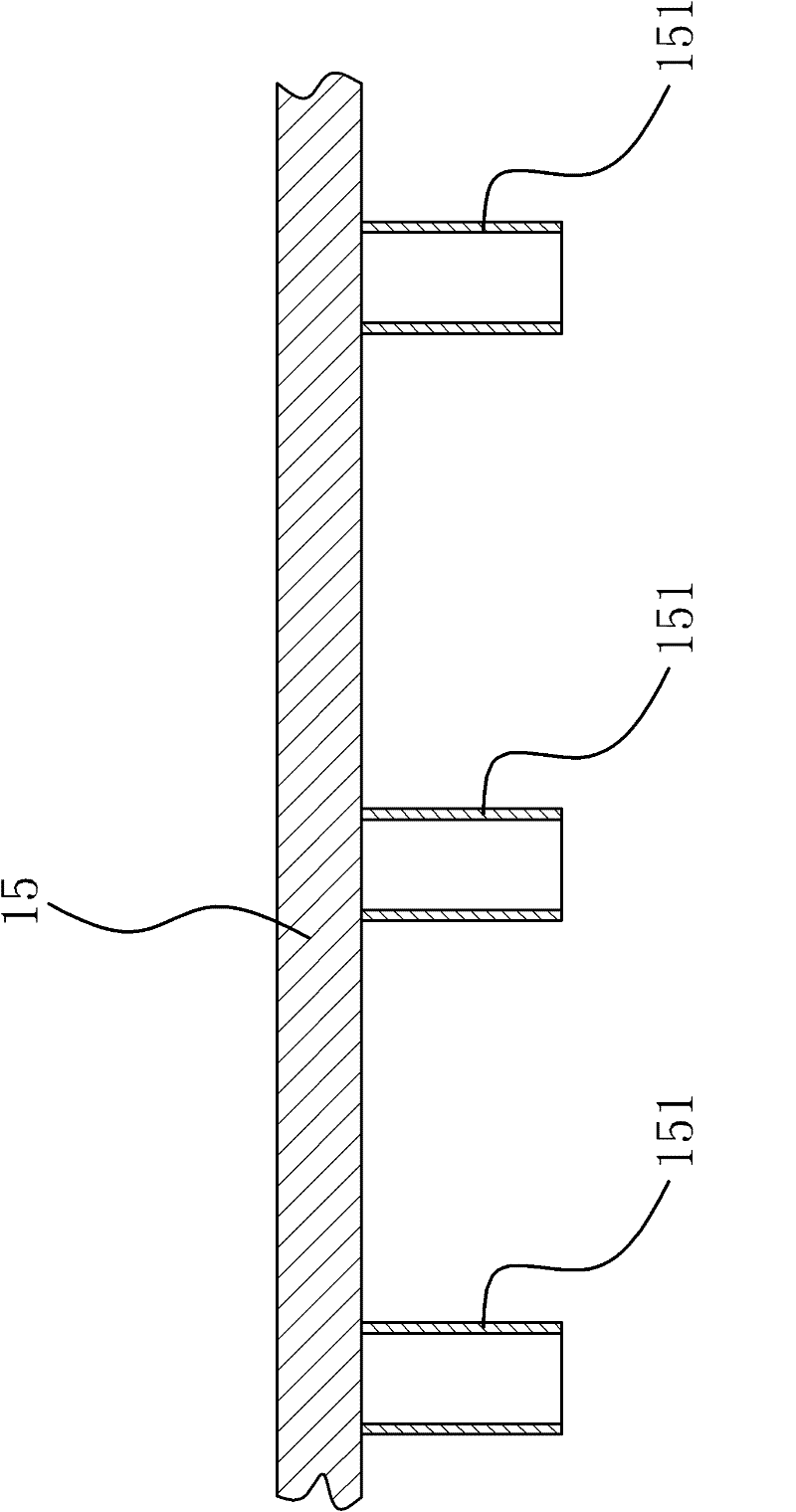

[0049] The content in the second embodiment is roughly the same as that in the first embodiment, the difference is that the tube expansion equipment in the first embodiment includes an upper tube expansion device and a lower tube expansion device, while the tube expansion device in the second embodiment The tube expanding device includes a tube expanding device and a positioning frame 15 for positioning the tube.

[0050] Specifically, the positioning frame 15 is fixed on the carriage 3, such as image 3 As shown, the positioning frame 15 has a number of positioning rods 151 which are the same in number as the expansion rods 4 and whose positions correspond to one-to-one. The positioning rods 151 are used to position the pipe fittings. The structure is simple and the positioning effect is good.

[0051]The tube expansion equipment in the second embodiment is used to expand several tube fittings on a tube sheet. The working principle of the tube expansion equipment is as follow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap